Method for judging tobacco leaf yellowing degree and baking progress in tobacco backing and yellowing stage

A technology for tobacco leaves at the yellowing stage, which is applied in the field of judging the degree of yellowing of tobacco leaves during the yellowing stage of flue-cured tobacco curing and the curing process, and can solve the problems of inconsistent baking judgment standards, low relative chlorophyll content, and high carotenoid content. To achieve the effects of easy operation and handling, improvement of tobacco leaf quality, gloss and oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

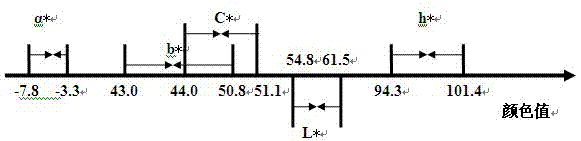

[0030]From 2011 to 2012, a flue-cured tobacco curing experiment was carried out at the curing room base of Fuquan City, Guizhou Provincial Tobacco Science Research Institute. Take 10 samples and use the colorimeter for rapid detection. Each leaf should choose to measure 6 points, that is, the middle position of the leaf tip, the middle part and the leaf base of the half leaf on both sides of the main vein, avoiding the main branch vein of the leaf, and then take the average value of the measurement. The average values of L*a*b*C*h* measured on 10 tobacco leaves are 65.2, 0.2, 53.6, 53.8, and 90.7. Three of the data in this group are in the range of 6 to 70% yellow value, and two values are close to , then the degree of yellowing is defined as 6-70% yellow; the average value of the pigment content and its ratio is 0.13, 0.11, 1.10 measured by taking 3 pieces, 2 of which are in the range of 6-70% yellow, and 1 value is close to , the degree of yellowing is defined as 6 to 7...

Embodiment 2

[0032] In 2013, a flue-cured tobacco (K326, Bina No. 1, Gui No. 2, Nanjiang No. 3, Jiucaiping No. 2 and other varieties) tobacco leaf curing test was carried out at the Longgang curing room base of Guizhou Tobacco Science Research Institute. During the curing process, 10 tobacco leaves were sampled during the yellowing stage, and the color difference meter was used to quickly detect the average values of L*a*b*C*h* of 10 tobacco leaves were 59.5, -4.9, 49.6, 50.1, 96.0, all If the values are all within the range of 2 to 3 percent yellow, then the degree of yellowing is defined as 2 to 3 percent yellow; at the same time, the average values of chlorophyll, carotenoid content and their ratio are 0.46, 0.20, and 2.33, and all values are in the If it is within the range of 2-30% yellowing area, the yellowing degree of tobacco leaves is defined as 2-30% yellowing; the two judgments are basically consistent. According to the method of curing, the top quality of the tobacco le...

Embodiment 3

[0034] In 2013, a tobacco leaf curing test in a flue-cured tobacco oven was carried out at the Kaiyang Longgang curing room base of Guizhou Tobacco Science Research Institute. Sampling was taken during the yellowing stage of the tobacco leaves during the curing process, and the color difference meter was used for rapid detection, and the tobacco leaf pigment content and its ratio were detected. Baking operation was carried out according to the measurement data results. As a result, the quality of tobacco leaves was increased by 3.28%, the appearance quality of tobacco leaves was improved, and the overall quality was significantly improved.

[0035] Experts have appraised this flue-cured tobacco curing technology, and the measured data results are consistent with the degree of yellowing of flue-cured tobacco leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com