A High-Precision Dual-Frequency Simultaneous Measurement of Laser Heterodyne Interferometry Phase Vibration Optical Path

A technology for measuring laser and heterodyne interference. It is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc. It can solve the problem of low accuracy and achieve the effects of high phase measurement accuracy, high precision and simple signal processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

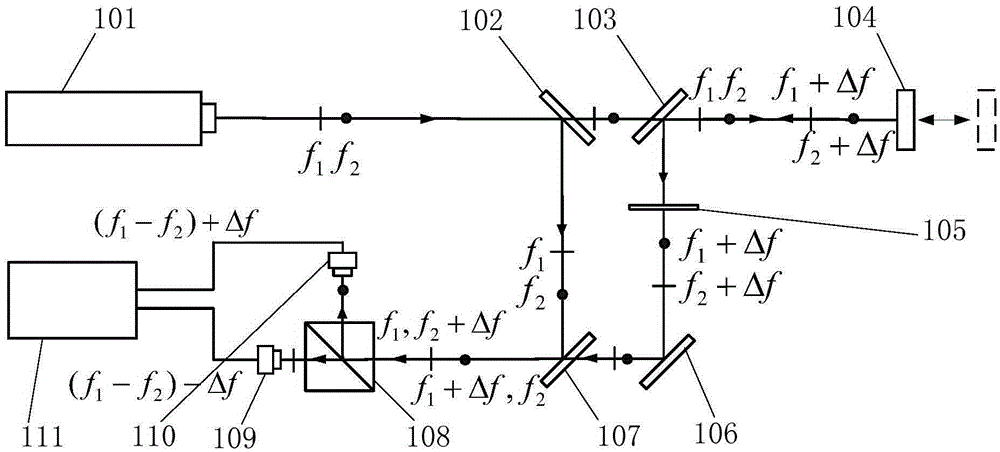

[0014] Please refer to the accompanying drawings, the dual-frequency laser source (101) adopts a transverse Zeeman dual-frequency laser with a frequency difference of 3MHz, and sends out a pair of linearly polarized light with a wavelength of 633nm orthogonal to each other, and its frequency components parallel and perpendicular to the paper surface They are f1 and f2 respectively, and the frequency difference is 5MHz. The first half-mirror (102) is k9 optical glass coated with a semi-permeable film, and the light beam is divided into two parts after passing through (102), both of which contain f1 and f2 frequency components. Wherein the reflected light is incident to the third half-mirror (107), (107) is the same product as (102), and the transmitted light is incident to the sample to be measured ( 104) Surface, (103) is also the same product as (102), (104) adopts a thin steel sheet driven by piezoelectric ceramics, and the vibration frequency is set to 500KHz. Due to the D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com