Sensor for distinguishing whether corrosion defects belong to inner surface of pipeline or outer surface of pipeline

A technology of internal and external surfaces and sensors, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of inability to distinguish defects, the inability to distinguish the inner surface or the outer surface of defects, etc., and achieve simple structure and installation arrangement, Small size, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

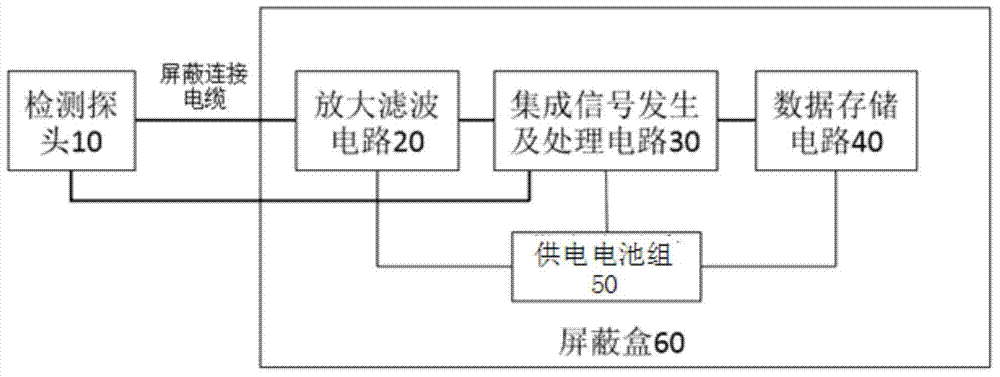

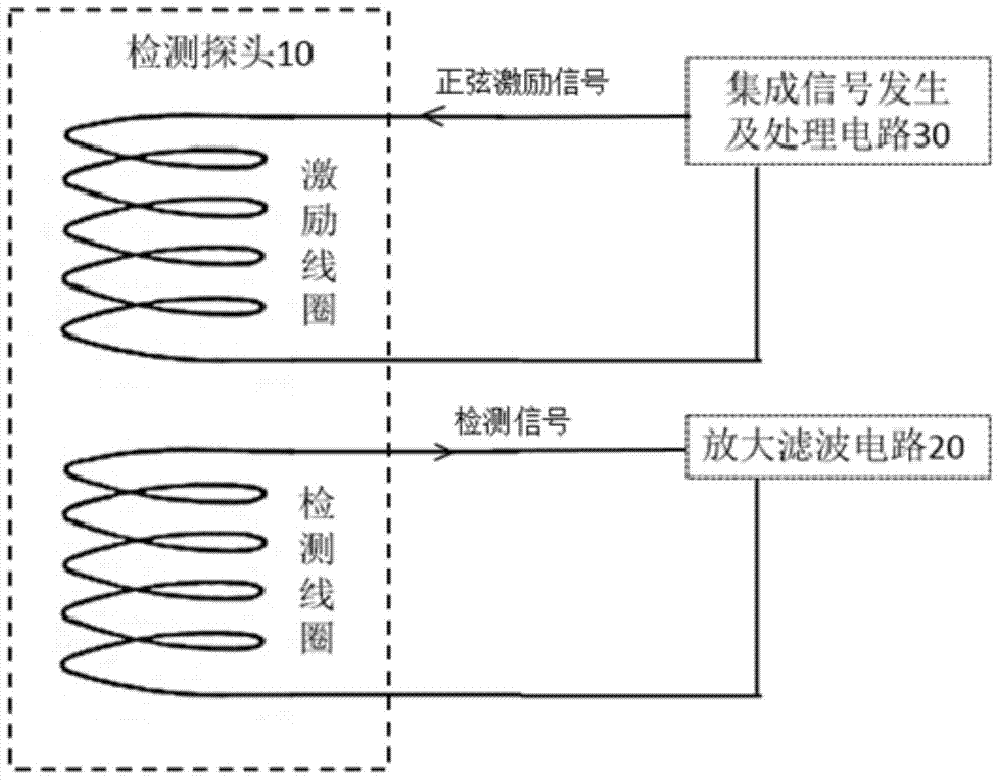

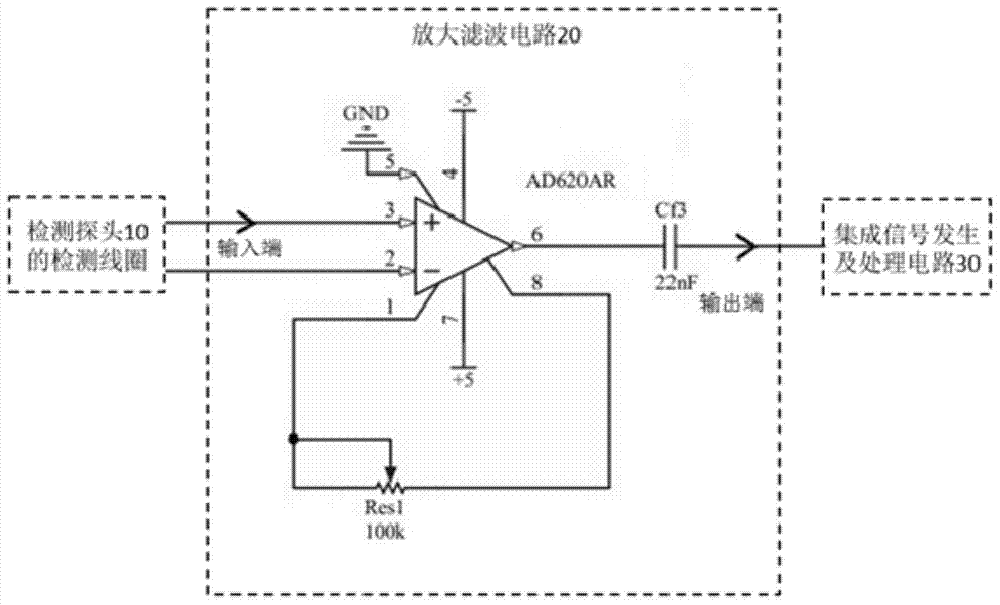

[0016] Such as figure 1 As shown, a sensor for distinguishing corrosion defects on the inner and outer surfaces of pipelines includes: a detection probe 10, an amplification filter circuit 20, an integrated signal generation and processing circuit 30, and a data storage circuit 40. The detection probe 10 includes two sets of coils, which are excitation coils and induction coils, such as figure 2 As shown, the excitation coil is connected with the integrated signal generating and processing circuit 30 for generating a spatial alternating electromagnetic field; the induction coil is connected with the amplification and filtering circuit 20 for detecting the electromagnetic signal of the inspected pipeline under the eddy current effect and inducing To output electrical signals, in this embodiment, the detection probe adopts a 50-turn hollow enameled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com