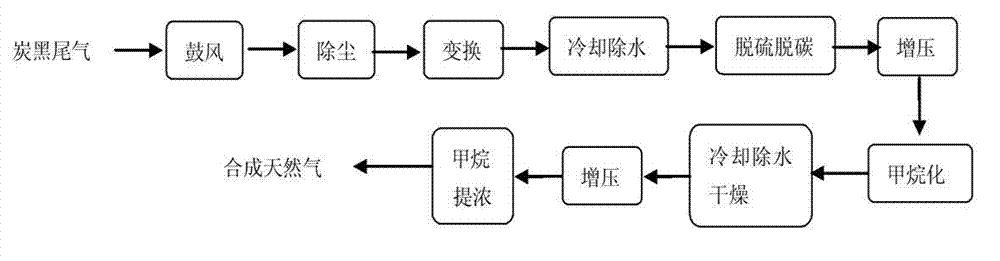

Process of preparing synthetic natural gas by carbon black tail gas

A technology for synthesizing natural gas and tail gas, applied in the petroleum industry, gas fuel, fuel and other directions, can solve problems such as environmental pollution, and achieve the effects of high heat utilization rate, high reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] According to the current production process of carbon black by the oil furnace method, after passing through the three-stage cyclone separator and the pulse bag filter, the temperature of the carbon black tail gas drops to 80-140°C, and this gas is the raw material gas of the present invention.

[0053] The carbon black tail gas from the carbon black plant at about 140°C (see Table 1 for the composition) is pressurized to 80kpa by the blower, and after dust removal by the bag filter, it enters the shift reaction preheater and is heated to 200°C, and the outlet temperature of the shift reaction gas is 250°C , the gas residence time is 50s. The shift reaction preheater uses the heat released by the shift reaction to heat the shift reaction intake air, and then enters the sulfur-tolerant shift reactor. Under the action of a common sulfur-tolerant shift catalyst, 42% of the CO and water in the gas The steam undergoes a sulfur-tolerant shift reaction (see equation 1). At the...

Embodiment 2

[0070] The carbon black tail gas from the carbon black factory at about 101°C (see Table 2 for the composition) is separated from gas and water, pressurized by a blower to 50kpa, and enters the ceramic filter. The filter time of the ceramic filter is 5 minutes, and the blowback is 1 minute. Blow alternately. After passing through the ceramic filter, the dust content of the gas is reduced to 5-10mg / Nm 3 .

[0071] The dedusted gas enters the shift reaction preheater and is heated to 250°C, and then enters the shift reactor. Under the action of the catalyst (QSC-3 sulfur-resistant shift catalyst commercially available from a domestic company), 52% of the CO and water vapor in the gas Sulfur tolerance shift reaction occurs (see reaction formula 1). The outlet temperature of the shift reaction gas is 320° C., the gas residence time is 30 s, and the start-up and heat utilization methods of the shift reaction are the same as those in Example 1. The cooled mixed gas enters the coo...

Embodiment 3

[0084] The carbon black tail gas from the carbon black plant at about 120°C (see Table 5) is pressurized by the blower to 70kpa, enters the bag filter for dust removal, enters the shift reaction preheater to be heated to 250°C, and then enters the shift reactor. Under the action of K8-11 conversion catalyst), 48% of CO in the gas undergoes a conversion reaction with water vapor (see reaction formula 1), the outlet temperature of the conversion reaction gas is 310°C, and the gas residence time is 40s. The heater preheats the raw material mixture, and the start-up and heat utilization methods of the shift reaction are the same as those in Example 1. The main components of the mixed gas exiting the shift reaction system are CO, CO 2 、H 2 , N 2 and water vapor, the mixed gas enters the cooler to be cooled to normal temperature and then enters the gas-water separator to separate the liquid water and then enters the chemical solvent alcoholamine absorption method desulfurization a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com