Non-sintered slag soil wall body block and preparation process thereof

A preparation process and non-sintering technology, applied in the field of non-sintered slag wall blocks, can solve the problems of secondary pollution, emission, consumption of large heat energy, etc., and achieve the effect of protecting cultivated land, high compressive strength, and saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The main raw materials of the non-sintered muck wall, by dry weight, include the following components in parts by weight:

[0041] Engineering slag 81 parts by weight

[0042] 32.5 cement 12 parts by weight

[0043] Fine stone 7 parts by weight

[0044] Modification additive 0.05 parts by weight.

[0045] After the above-mentioned engineering dregs are treated, the particle size shall not exceed 3mm.

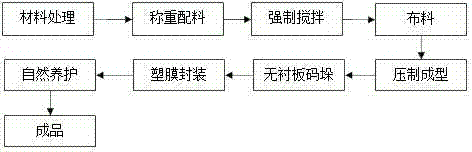

[0046] Such as figure 1 Shown, the preparation technology of described non-fired slag solid standard brick is:

[0047] The engineering slag is crushed to a particle size of no more than 3mm, and the moisture content is controlled to 3%-8% after natural air drying. Mix 81 parts of engineering slag, 12 parts of 32.5 cement, and 7 parts of fine stone, and add 0.05 part of modified The aqueous solution of the additive adjusts the water content of the mixture to 10%-15%. The brick adobe is pressed by machine, wherein semi-dry pressing is adopted during pressing, and the...

Embodiment 2

[0051] The main raw materials of the non-sintered muck wall, by dry weight, include the following components in parts by weight:

[0052] Engineering slag 79 parts by weight

[0053] 32.5 cement 13 parts by weight

[0054] Fine stone 8 parts by weight

[0055] Modification additive 0.03 parts by weight.

[0056] After the above-mentioned engineering dregs are treated, the particle size shall not exceed 3mm.

[0057] Such as figure 1 Shown, the preparation technology of above-mentioned non-sintered slag soil porous brick is:

[0058] The engineering slag is crushed and processed to a particle size of no more than 3mm, and the moisture content is controlled to 3%-8% by natural air drying. 79 parts of engineering slag, 13 parts of 32.5 cement, and 8 parts of fine stone are mixed and 0.03 parts of modification are added. The aqueous solution of the additive adjusts the water content of the mixture to 10%-15%. The brick adobe is pressed by machine, wherein semi-dry pressing i...

Embodiment 3

[0062] The main raw materials of the non-sintered muck wall, by dry weight, include the following components in parts by weight:

[0063] Engineering slag 81 parts by weight

[0064] 32.5 cement 10 parts by weight

[0065]Fine stone 9 parts by weight

[0066] Modification additive 0.04 parts by weight.

[0067] After the above-mentioned engineering dregs are treated, the particle size shall not exceed 3mm.

[0068] Such as figure 1 Shown, the preparation technology of above-mentioned non-sintered slag earth hollow brick is:

[0069] The engineering slag is crushed to a particle size of no more than 3mm, and the moisture content is controlled by natural air drying to 3%-8%. Mix 81 parts of engineering slag, 10 parts of 32.5 cement, and 9 parts of fine stone and add 0.04 parts of modified The aqueous solution of the additive adjusts the moisture content of the mixture to 10%-15%. The brick adobe is pressed by machine, wherein semi-dry pressing is adopted during pressing, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com