Manufacturing method of glass fiber-reinforced plastic integrated septic tank storage pot

A manufacturing method and integrated technology, applied in the field of storage tank manufacturing, can solve problems such as difficult control, quality problems, and high equipment requirements, and achieve the effects of avoiding volatilization and splashing, improving material density, and evenly distributing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

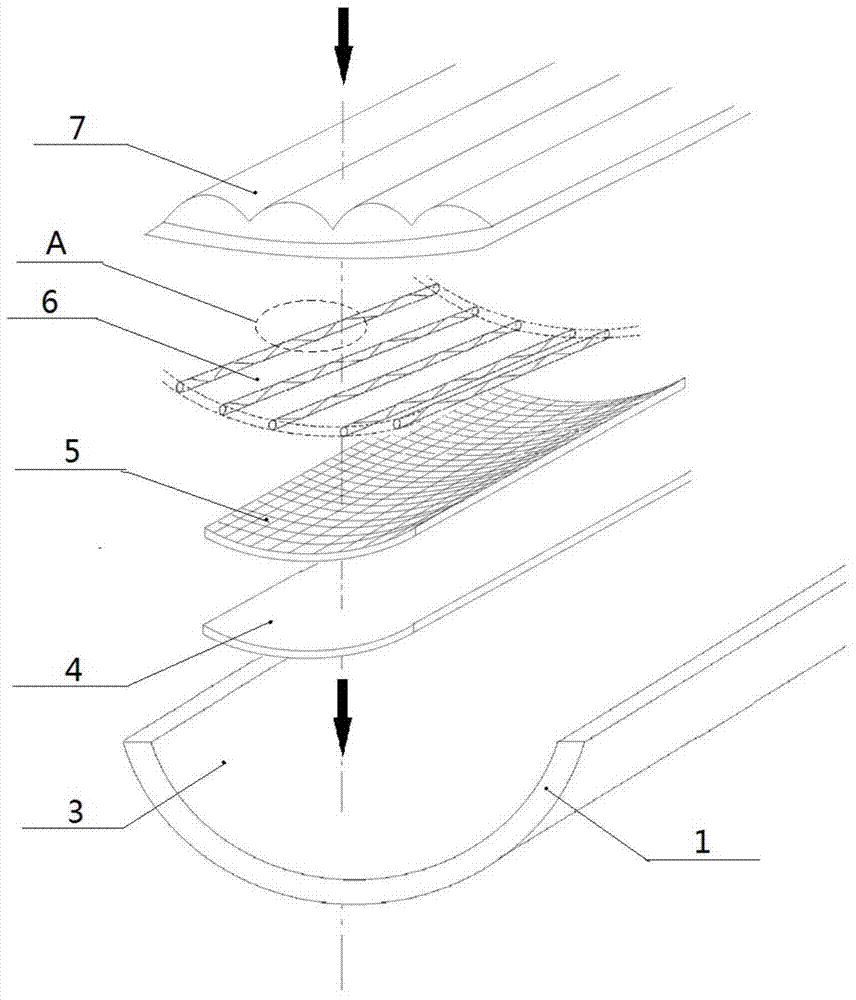

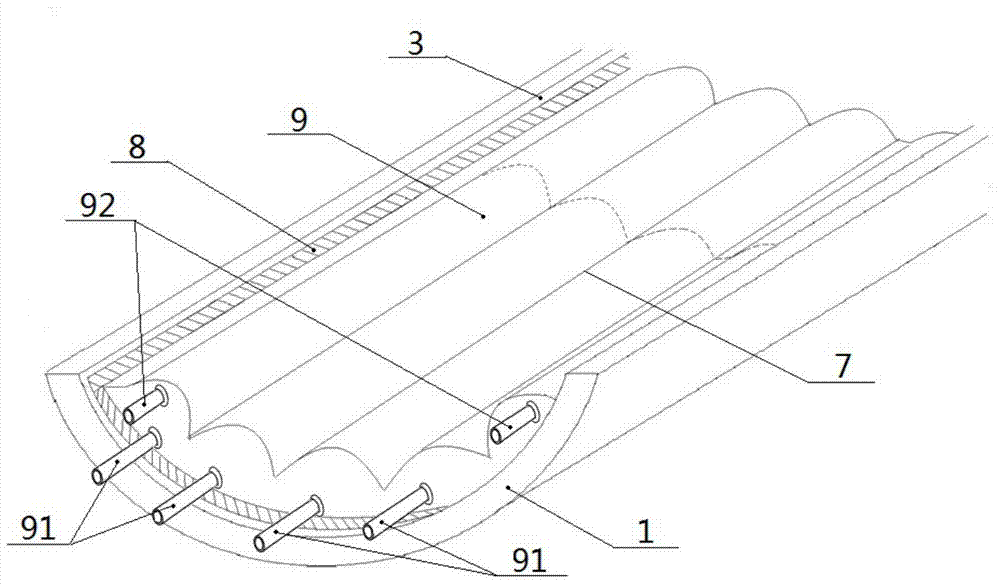

[0018] Figures 1 to 3 Shown is the first implementation of the present invention to make the cylinder and the head. The septic tank storage tank is usually composed of a hollow cylinder with a cylindrical shape and a spherical head at each end. Therefore, the first thing to do to manufacture a storage tank is to select the matching cylinder mold 1 and seal. Head Mold 2. Because the head is smaller than the cylinder and its geometric shape is simple, the manufacturing process of the cylinder is mainly explained.

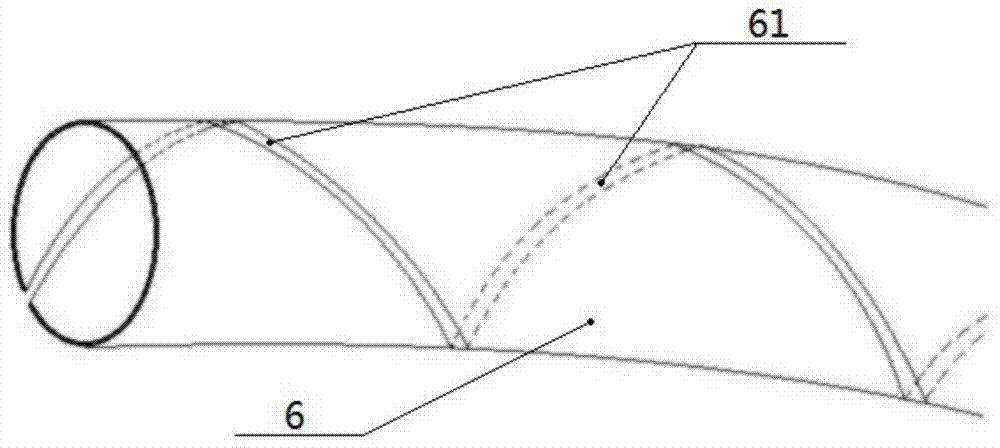

[0019] Before starting to make the barrel 10, first clean the inner wall 3 of the barrel mold and then spray a layer of gel coat to facilitate subsequent demoulding, and continue the process after the gel coat dries; figure 1 As shown, on the inner wall 3 of the cylinder mold, lay a dense glass fiber layer 4 according to the number of layers designed, and cling to the inner wall 3 of the mold, so that its shape is as consistent as possible with the inner wall. It s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com