Trimethyl borate in epoxy resins

A technology of trimethyl borate and trialkyl borate, which is applied in the field of thermosetting products and can solve the problems of unsuitable prepregs or laminated materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

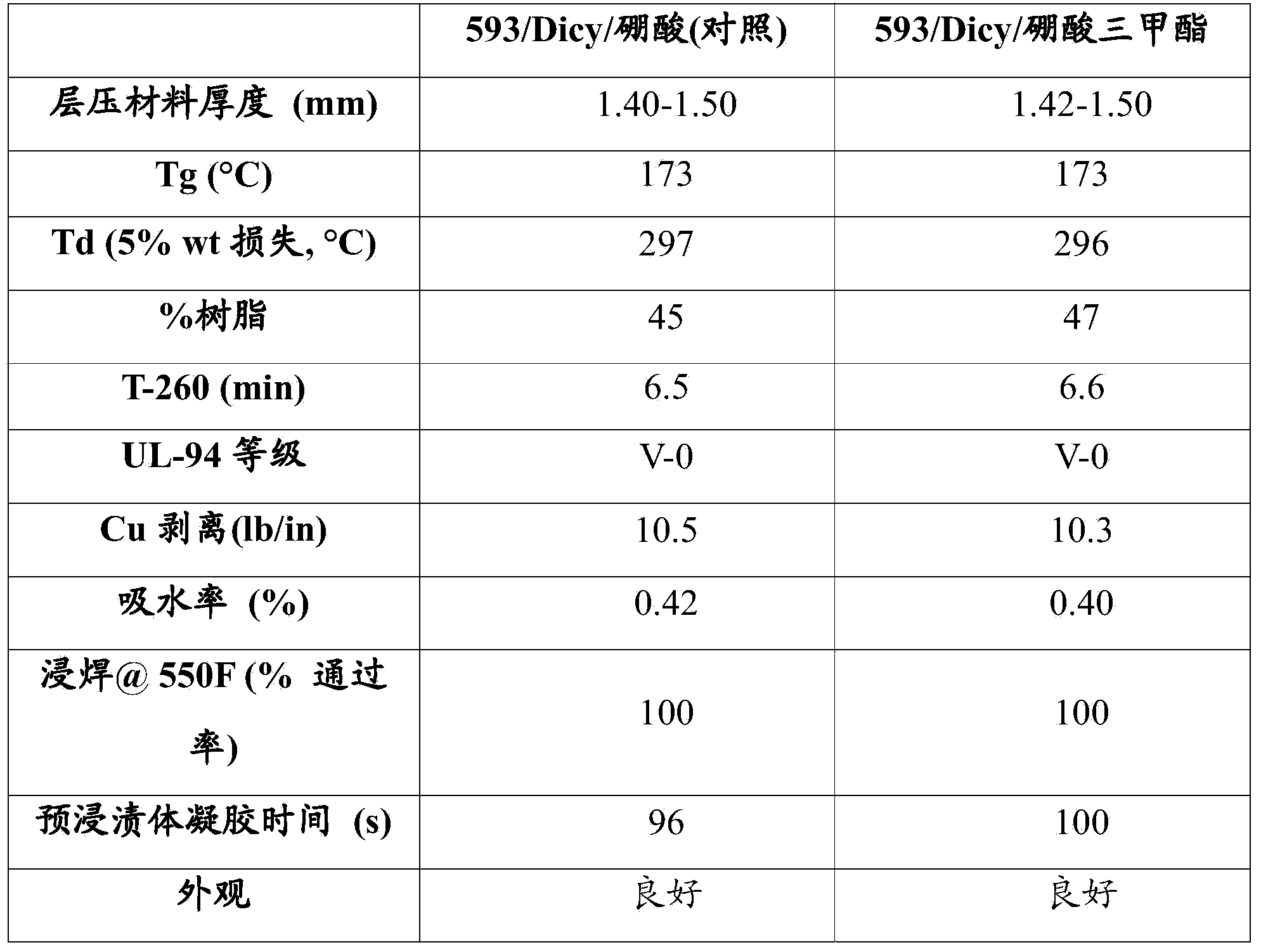

[0106] Boronic acid example by der TM 593 Use proper mixing ratio of DER TM 592A80, Dowanol PM, boronic acid in methanol (BAM), and methanol (6167 g) were prepared. The mixture was then added to a dicyandiamide solution (10 wt% in 50 / 50 Dowanol™ PM and dimethylformamide, 1480 g) and mixed for 15 minutes on a shaker or with a stirring blade. To this solution was added 2-methylimidazole (20 wt% solution in Dowanol PM, 86.14 g) and the mixture was allowed to mix at ambient temperature for 1 hour. The varnish can be used as is for further testing. A number of laminate qualities were tested on the varnishes prepared from the examples and are shown in Table 1 as a control.

Embodiment 2

[0108] Trimethyl borate Example by DER TM593 was prepared using DER592A80, Dowanol PM and pure trimethyl borate (4612 g) in appropriate mixing ratios. The mixture was then added to a dicyandiamide solution (10 wt% in 50 / 50 Dowanol PM and dimethylformamide, 1107 g) and mixed for 15 minutes on a shaker or with a stirring blade. To this solution was added 2-methylimidazole (20 wt% solution in Dowanol PM, 64.6 g) and the mixture was allowed to mix at ambient temperature for 1 hour. The varnish can be used as is for further testing. A number of laminate qualities were tested on the varnishes prepared from the examples and are shown in Table 1 as a control.

[0109] Table 1

[0110]

[0111] As demonstrated in Table 1, compositions containing trimethyl borate (TMB) had qualities similar to those containing boric acid (BAM). There was no difference within experimental error between the two systems.

Embodiment 3

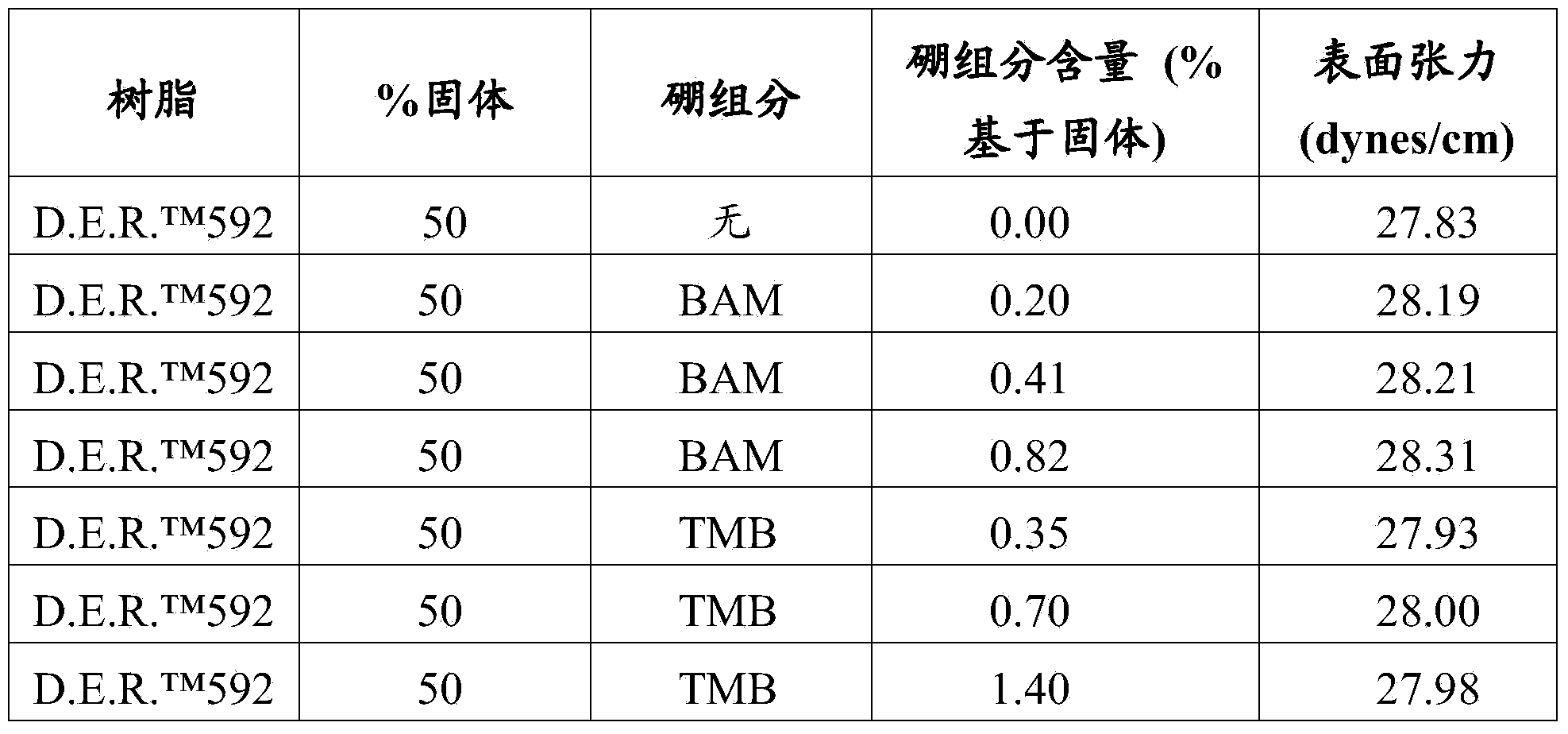

[0113] by submitting to DER TM 592 Epoxy Resin Added Methanol and Dowanol TM PM to prepare sample preparations. BAM and TMB were then added separately to the samples while maintaining the same solvent levels and mixing ratios. The resin mixture was then mixed well on a shaker at ambient conditions for 1 hour. Dowanol TM PM is used to dissolve the mixture. These samples were used for contact angle and surface energy measurements.

[0114] Surface tension and contact angle of samples containing BAM / TMB

[0115] Surface tension and contact angle measurements were done using a Cahn dynamic contact angle analyzer (DCA). By monitoring the change in force when one object touches another, DCA calculates the contact angle. A microscope coverslip 24mm x 30mm x 0.16mm was precisely measured and attached to the instrument. A 60mm diameter x 15mm deep glass dish was filled with the sample solution to a depth of approximately 6-8mm. Raise the base until the coverslip is approximate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com