Cooling method and structure of closed type cooling system

A cooling system and cooling method technology, applied in cooling/ventilation/heating renovation, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of unstable output temperature, large setting capacity, insufficient cooler capacity, etc. The effect of stable output temperature, simplified system analysis, and improved system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

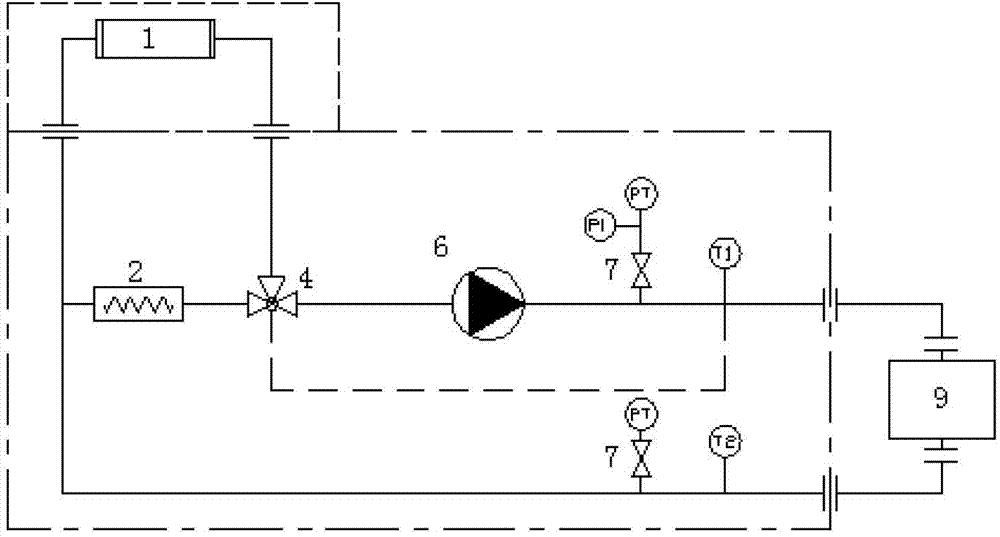

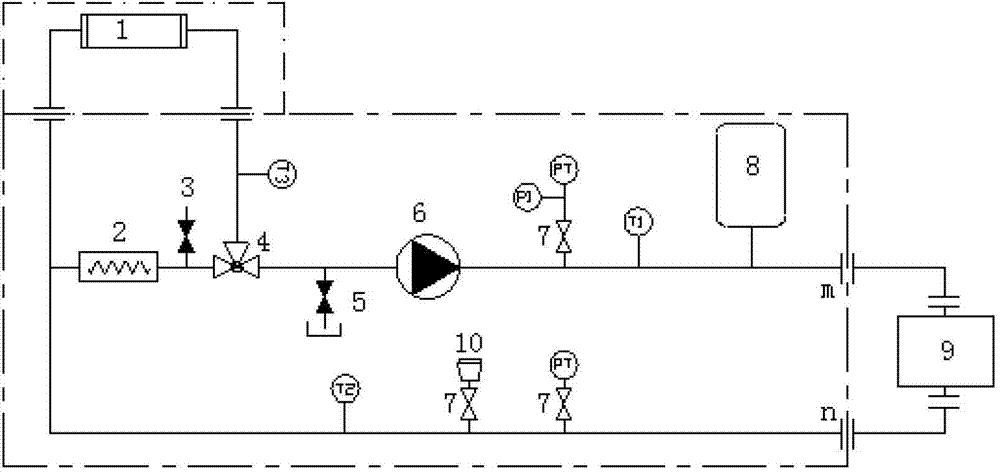

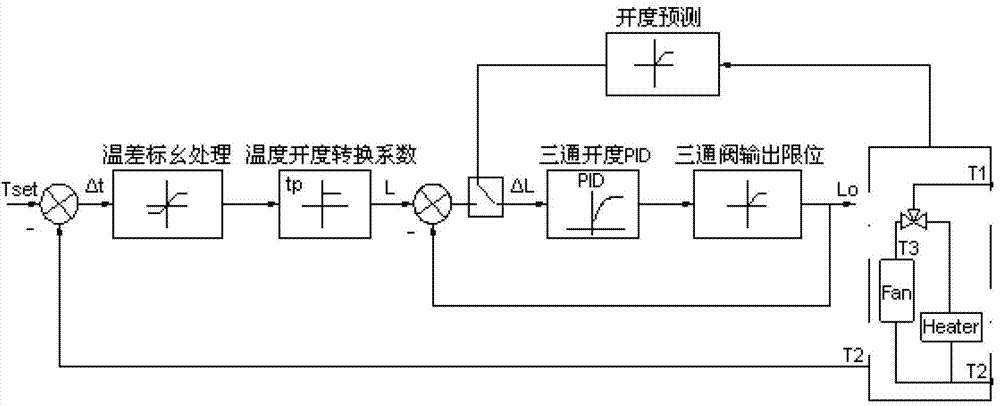

[0044] like figure 2 , 3 As shown, the closed cooling system of the present invention includes an air-water heat exchanger 1, a heater 2, an exhaust valve 3, a three-way valve 4, a sewage outlet 5, a circulating pump 6, an instrument shut-off valve 7, and a pressure regulator 8. Cool the object 9 and the measuring point joint 10. The cooling object 9 may be any object cooled by water, such as a fan converter and the like. The liquid circulated after the heat exchange of the cooling object 9 is pumped into the air-water heat exchanger 1 and the heater 2 through the circulation pump 6, and then merged through the three-way valve 4 and the flow ratio is controlled to prepare cooling liquid and supply it to the cooling object 9.

[0045] The present invention is a kind of cooling method of closed cooling system, and its concrete steps are:

[0046] (1) According to the calorific value of the cooling object 9, determine the fan that needs to be started in the air-water heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com