Optical fiber patch cord for high-power laser transmission

A fiber optic jumper and high-power technology, which is applied in the field of SMA connector fiber jumpers, can solve the problems of poor heat dissipation of glue, burning out optical fibers, and difficult processing, and achieve the effects of reducing processing requirements, improving reliability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

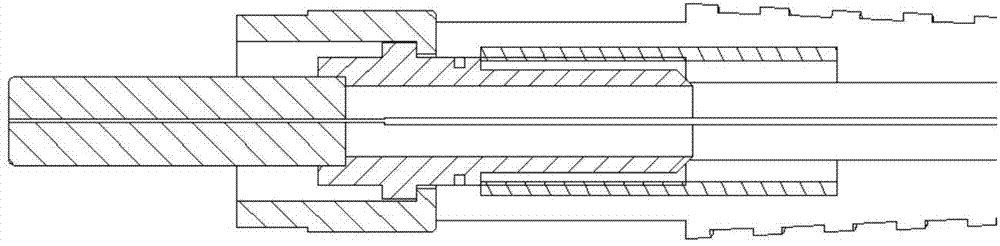

Image

Examples

Embodiment Construction

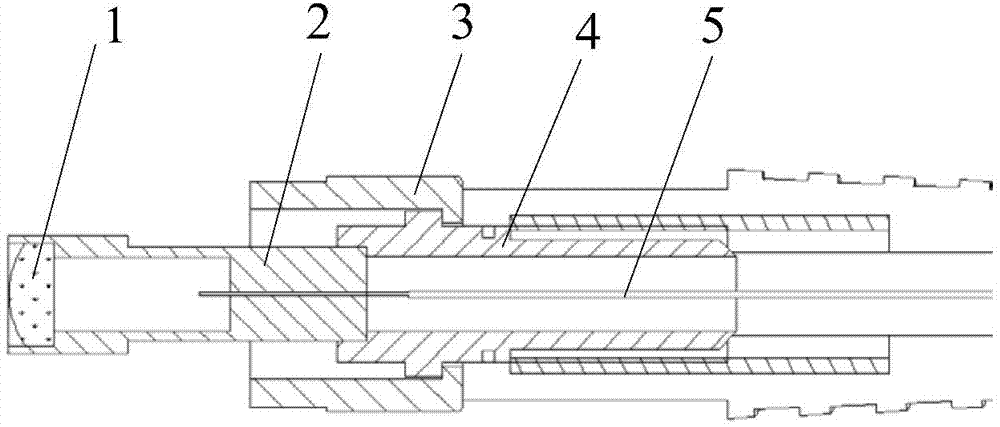

[0019] The present invention will be further described in conjunction with the accompanying drawings.

[0020] Such as figure 2 As shown, the present invention includes a collimating lens 1, a ferrule 2, a ferrule sleeve 4, a nut 3, and an optical fiber 5. One end of the ferrule 2 is fixed on the ferrule sleeve 4, and the center of the end of the ferrule 2 is provided with The hole with the same diameter as the optical fiber is used to fix the optical fiber 5; the ferrule sleeve 4 connects the ferrule 2 and the nut 3 together, and the optical fiber 5 passes through the ferrule sleeve 4 and is fixed in the hole of the ferrule 2; The straight lens 1 is fixed at the other end of the ferrule 2 , and the focal point of the collimator lens 1 is at the center of the end face of the optical fiber 5 . The optical fiber 5 is used to receive the light focused by the collimating lens 1 and transmit it. The collimating lens is a lens with a flat surface on one side and an aspheric surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com