PCB performance detection jig with heat dissipation function and impurity removal function

A technology for PCB boards and testing fixtures, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve the problems of high temperature of PCB boards, residual dust and waste, and low detection accuracy, so as to improve test accuracy and quickly The effect of testing and detecting high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

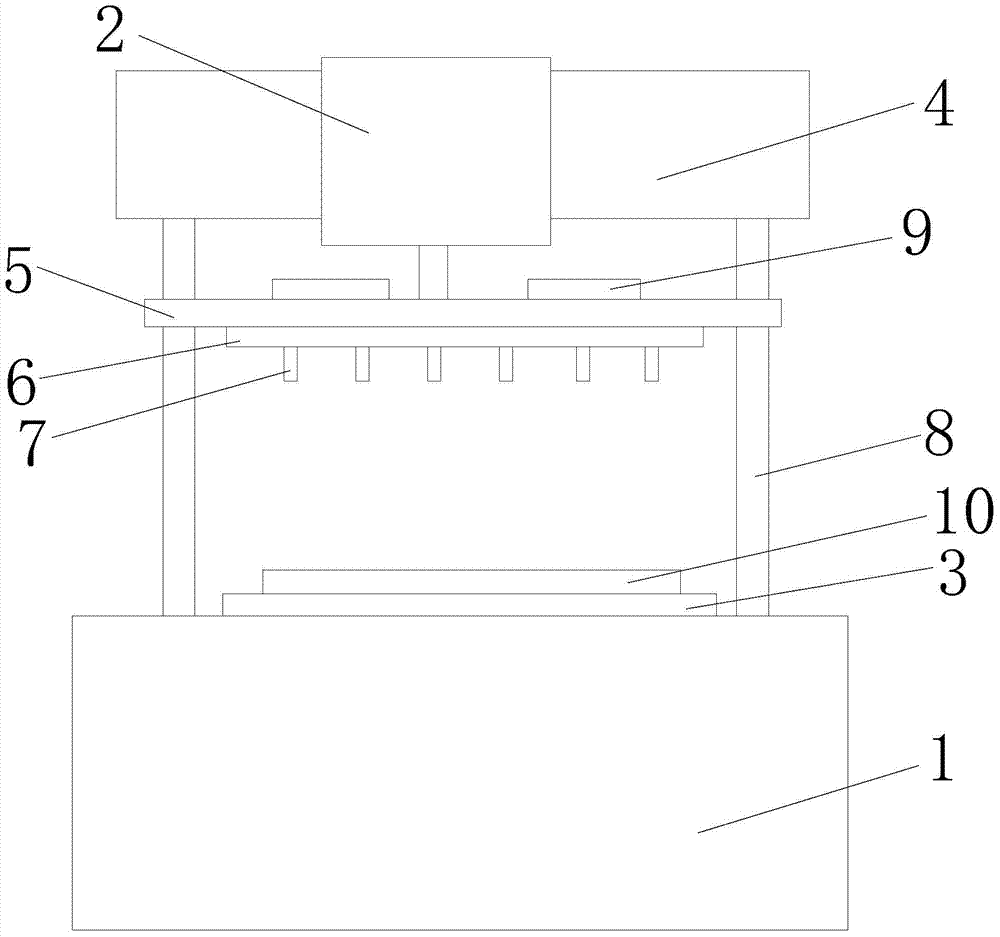

[0012] like figure 1 As shown, a PCB board performance testing fixture with heat dissipation and impurity removal functions includes a test bench 1, a servo motor 2, a placement board 3, an upper fixing board 4, a pressure board 5, a cushion board 6, a probe 7, and a guide rail 8 and blower 9, the top of test stand 1 is provided with the placement board 3 that is used to place PCB board 9, and described placement board 3 adopts copper to make, and described placement board 3 is provided with some water pipes, and described water pipe two ends A water inlet and a water outlet are respectively arranged.

[0013] An upper fixing plate 4 is arranged above the placing plate 3 , and a guide rail 8 is respectively arranged on both sides of the placing plate 3 between the upper fixing plate 4 and the test platform 1 . On the upper fixed plate 4, a servo motor 2 is arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com