Oxygen supply system for engine reusing test

A technology for supplying systems and engines, applied in the field of aerospace engines, can solve problems such as test hazards, operator safety threats, waste of low-pressure oxygen, etc., to ensure safety, prevent low control accuracy, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below with reference to the drawings and embodiments.

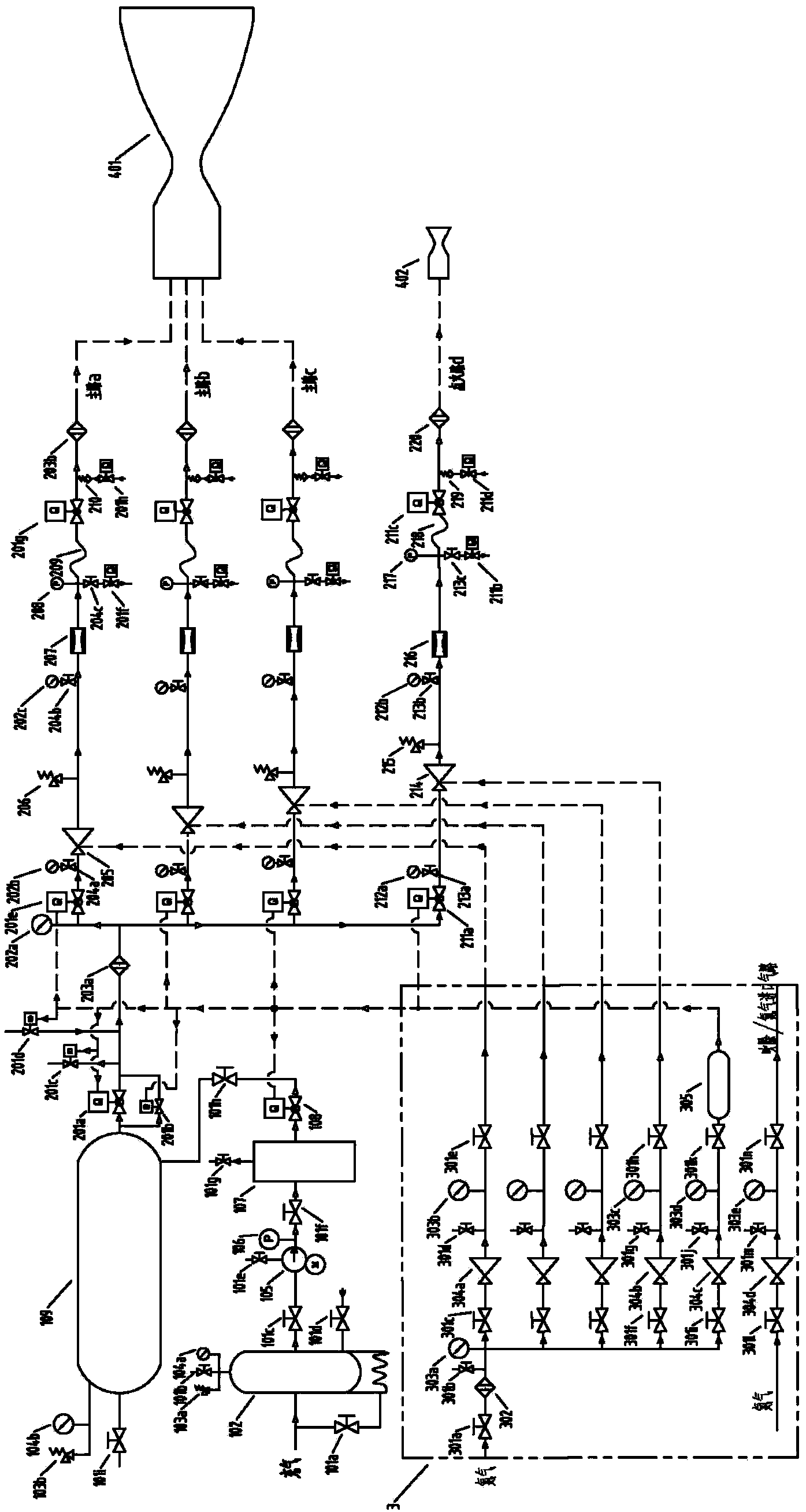

[0049] An oxygen supply system for repeated use of engine tests, such as figure 1 As shown, it includes an oxygen source system, an oxygen transport system, and a gas distribution table 3.

[0050] The oxygen source system includes manual shut-off valve (101a~101h), low pressure liquid oxygen storage tank 102, safety valve (103a, 103b), pressure gauge (104a, 104b), liquid oxygen pump 105, pressure sensor 106, vaporizer 107, pneumatic shutoff Valve 108, high-pressure oxygen storage tank 109 and pipelines.

[0051] The input of the low-pressure liquid oxygen storage tank 102 is connected to the inflation pipeline. The bypass of the inflation pipeline is provided with a manual shut-off valve 101a. The top of the low-pressure liquid oxygen storage tank 102 is connected to a safety valve 103a, a manual shut-off valve 101b, and a pressure gauge through a three-way conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com