Balance type hydraulic double-mold vulcanizer positioning-guiding device

A positioning-oriented, balance-type technology, applied in the field of positioning and guiding devices of a balance-type hydraulic dual-mode vulcanizer, can solve the problems of equipment accuracy damage, high equipment failure rate, and dynamic balance failing to meet requirements, and achieve stable equipment operation. Longer equipment life and better tire quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

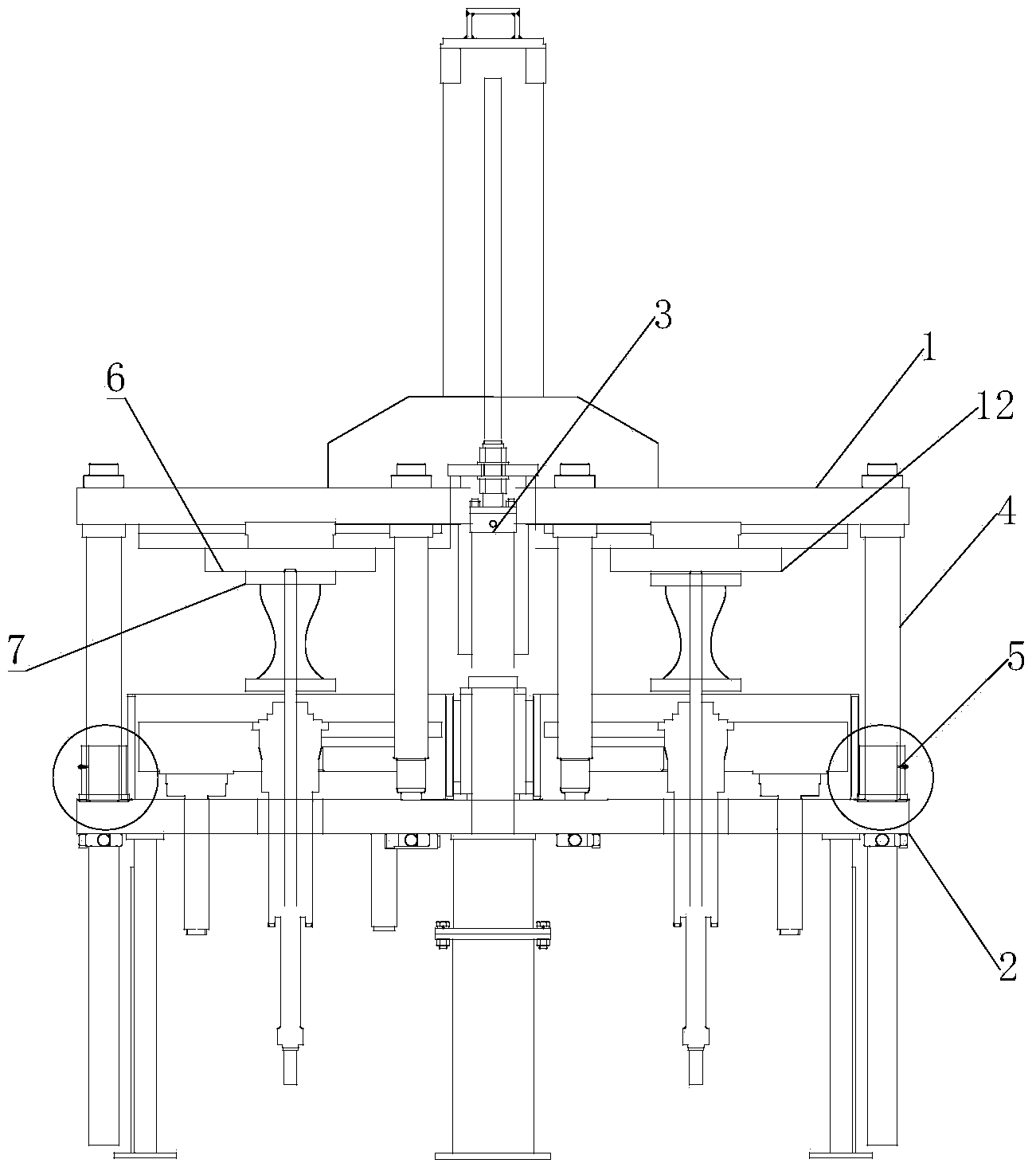

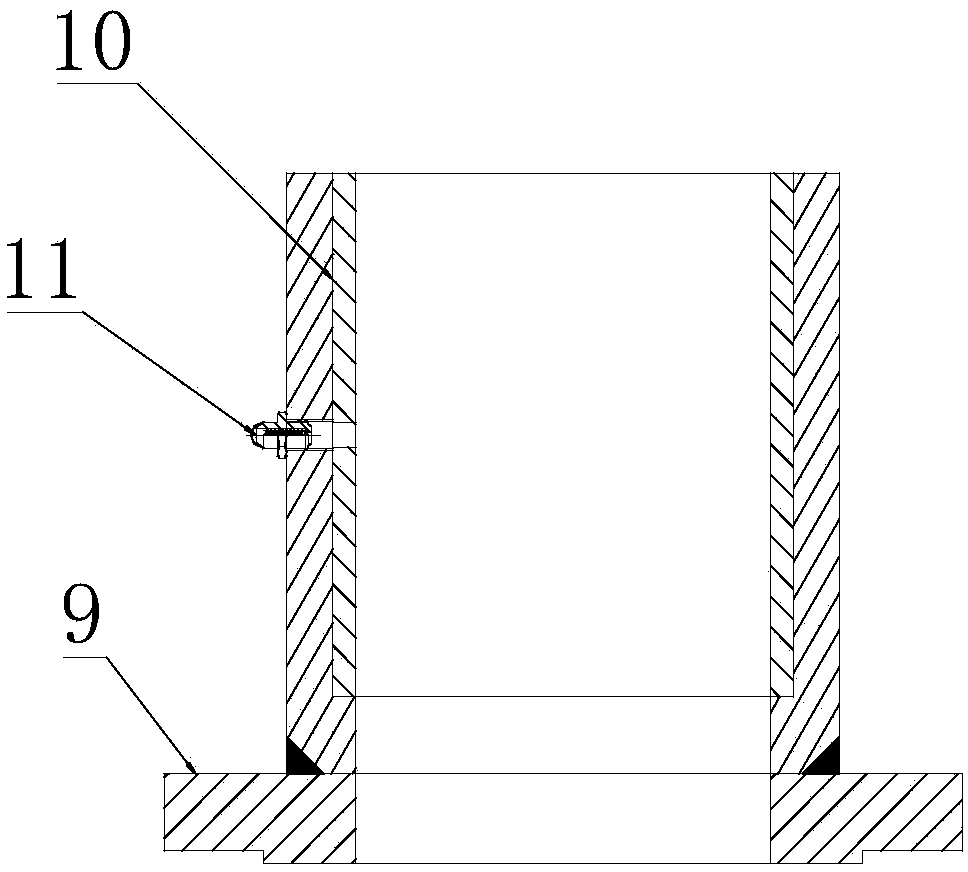

[0020] The positioning and guiding device of the balance-type hydraulic double-mode vulcanizing machine includes a frame on which an upper supporting plate 1 and a lower supporting plate 2 are arranged, and the upper supporting plate 1 is symmetrically provided with the lower supporting surface 6 of the upper left mold and the lower supporting surface of the upper right mold 12. The lower supporting surface 6 of the upper left mold and the lower supporting surface 12 of the upper right mold are provided with an upper capsule chuck 7, the upper supporting plate 1 and the lower supporting plate 2 are horizontal plates, and the upper supporting plate 1 and the lower supporting plate 2 are provided with a The linear guide rail, the linear guide rail includes the front linear guide rail 3 and the rear linear guide rail 8, the front linear guide rail 3 and the rear linear guide rail 8 are symmetrically arranged on the upper pallet 1 and the lower pallet 2; There are also two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com