Double-roll calendering machine for graphite radiating paper

A technology of calendering and graphite, which is applied in the direction of pressing rollers, etc., can solve the problems of low calendering precision and large roller runout, and achieve the effects of reducing roller runout, stable roller distance adjustment, and large reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

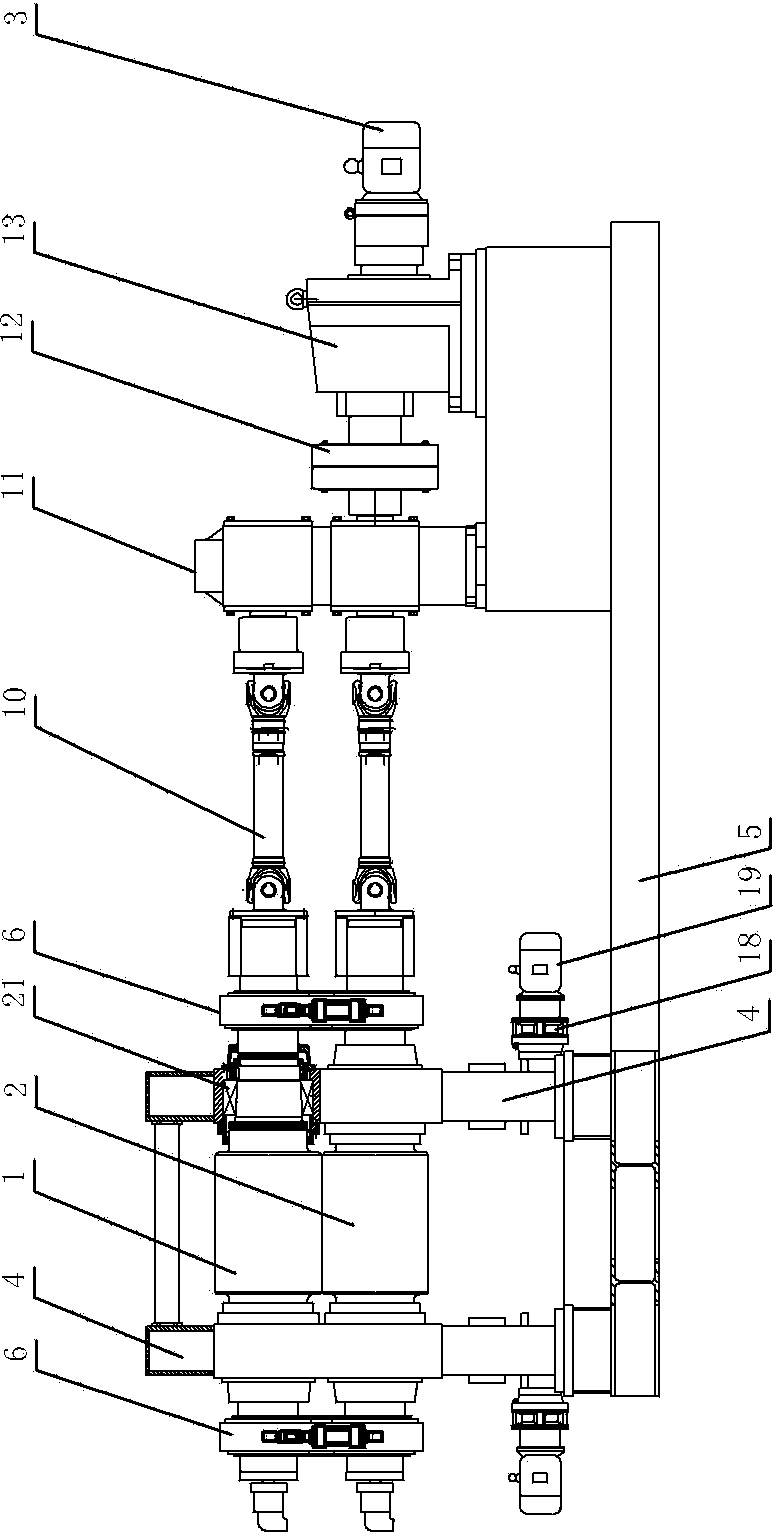

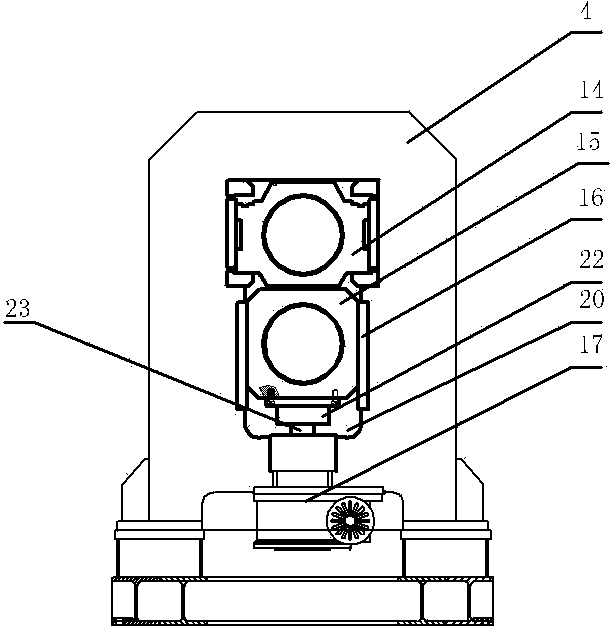

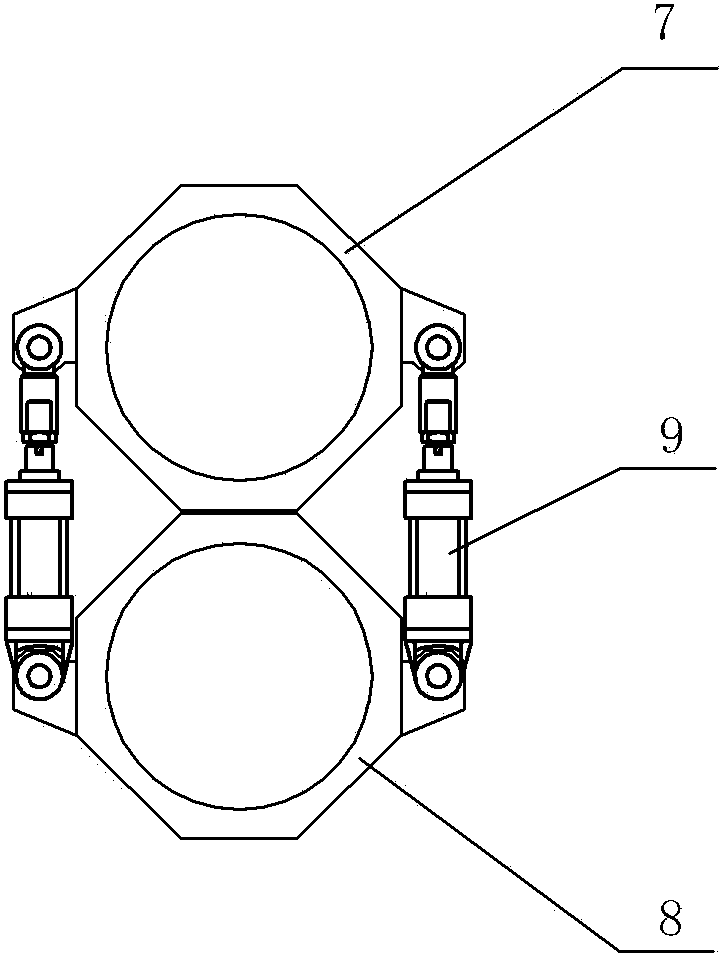

[0014] Such as figure 1 , figure 2 with image 3 As shown, the two-roll calender of graphite heat-dissipating paper includes an upper roller 1, a lower roller 2, a transmission device, a motor 3, a frame and a base 5. The upper roller 1 and the lower roller 2 are supported on the frame on both sides, and The upper roller 1 and the lower roller 2 are arranged in parallel, and the motor 3 drives the upper roller 1 and the lower roller 2 to move toward each other through a transmission device. The supporting ends of the upper roller 1 and the lower roller 2 are connected by the pre-load device 6. The pre-load device 6 includes an upper bearing seat 7, a lower bearing seat 8 and a hydraulic cylinder 9. The upper bearing seat 7 is installed on the supporting end of the upper roller 1, the lower bearing seat 8 is installed on the supporting end of the lower roller 2, and the two ends of the hydraulic cylinder 9 are respectively supported Upper bearing seat 7 and lower bearing seat 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com