Novel transmission device of combined machine

A transmission device and combination machine technology, which is applied to transmission device parts, mechanical equipment, belts/chains/gears, etc., can solve the problem that the concentricity and runout of the upper and lower dies cannot be guaranteed, and the concentricity and ellipse of the power shaft cannot be guaranteed. In order to reduce the vibration, increase the concentricity and stabilize the rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. However, the examples given are not intended to limit the present invention.

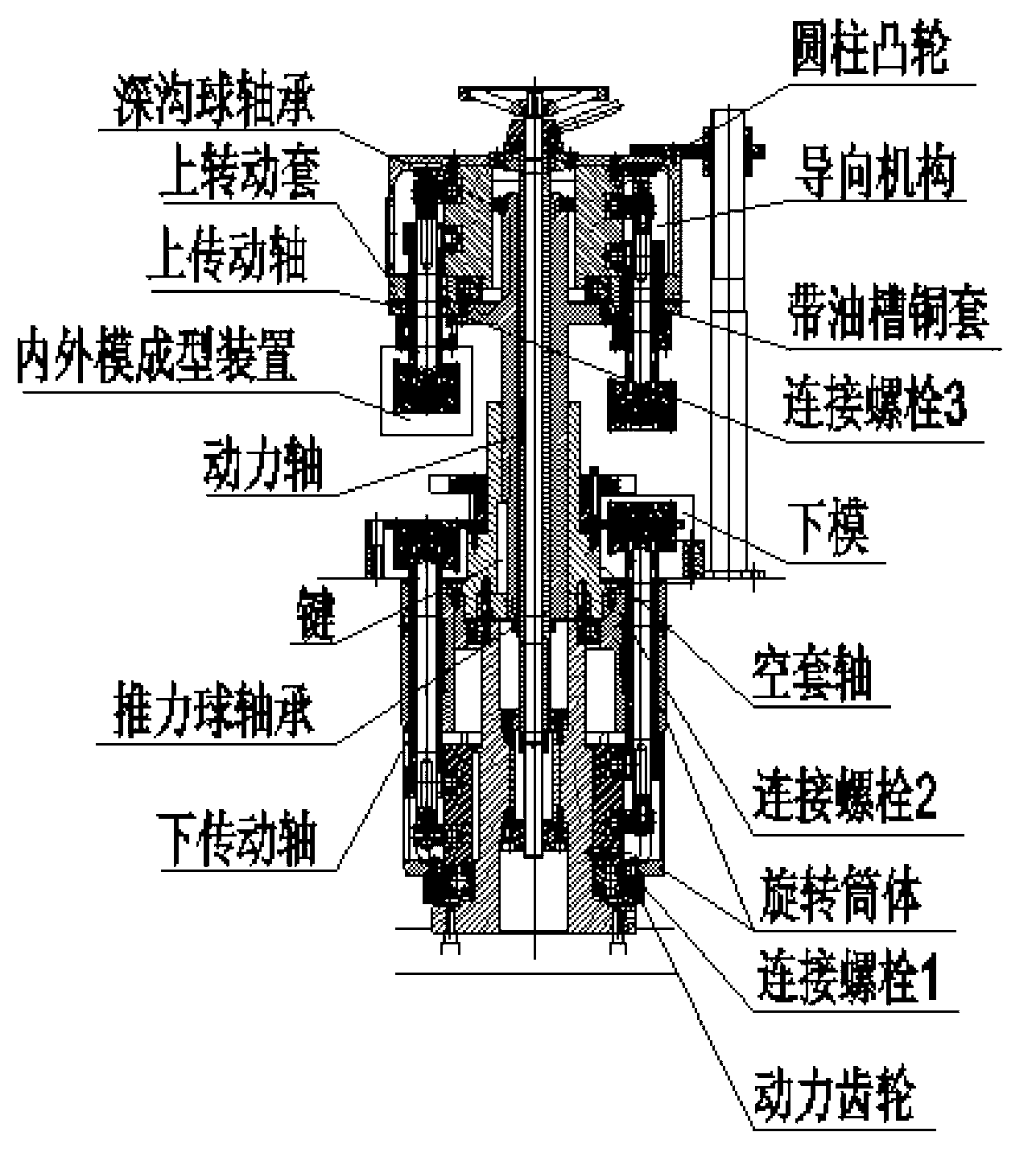

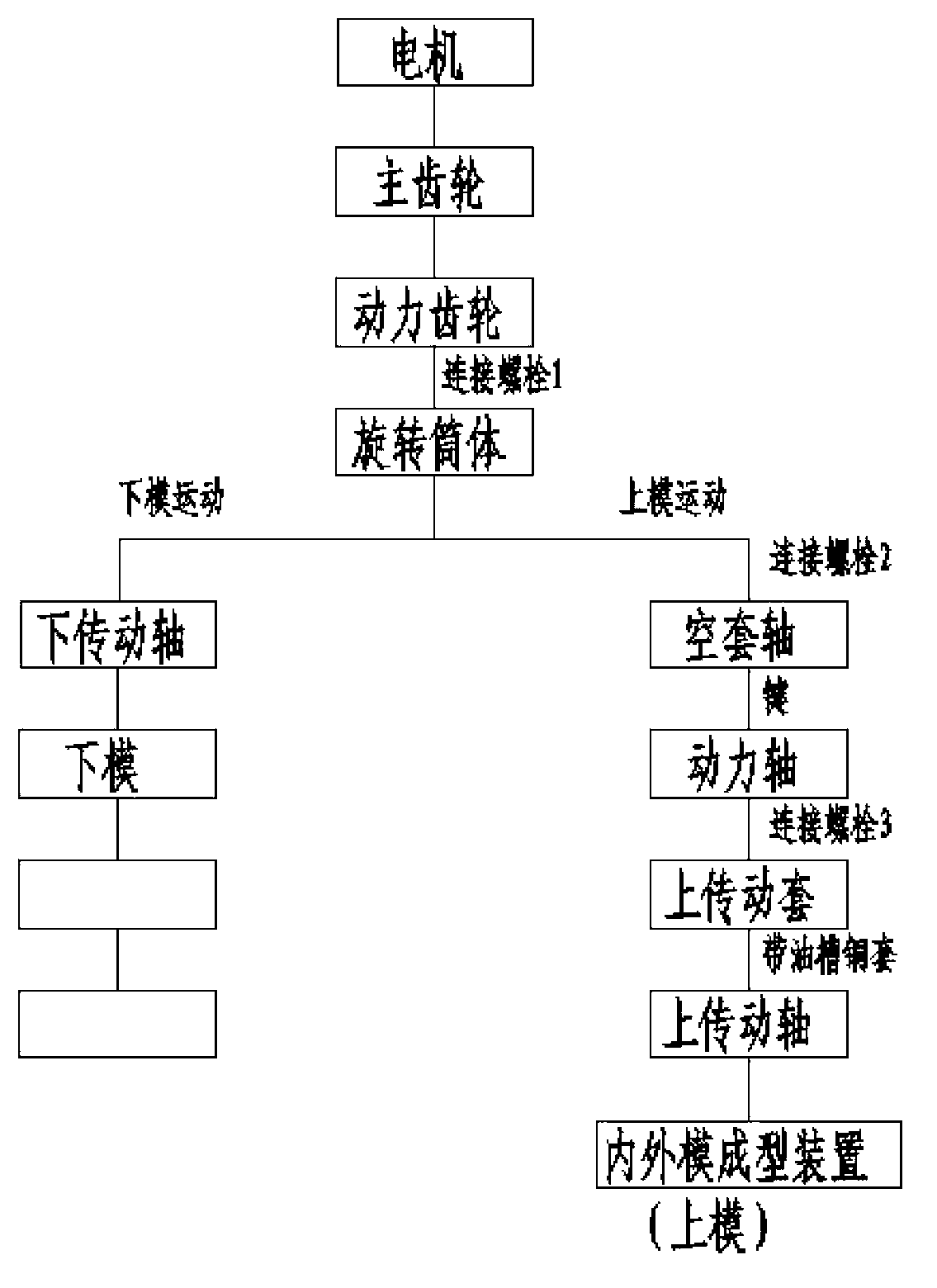

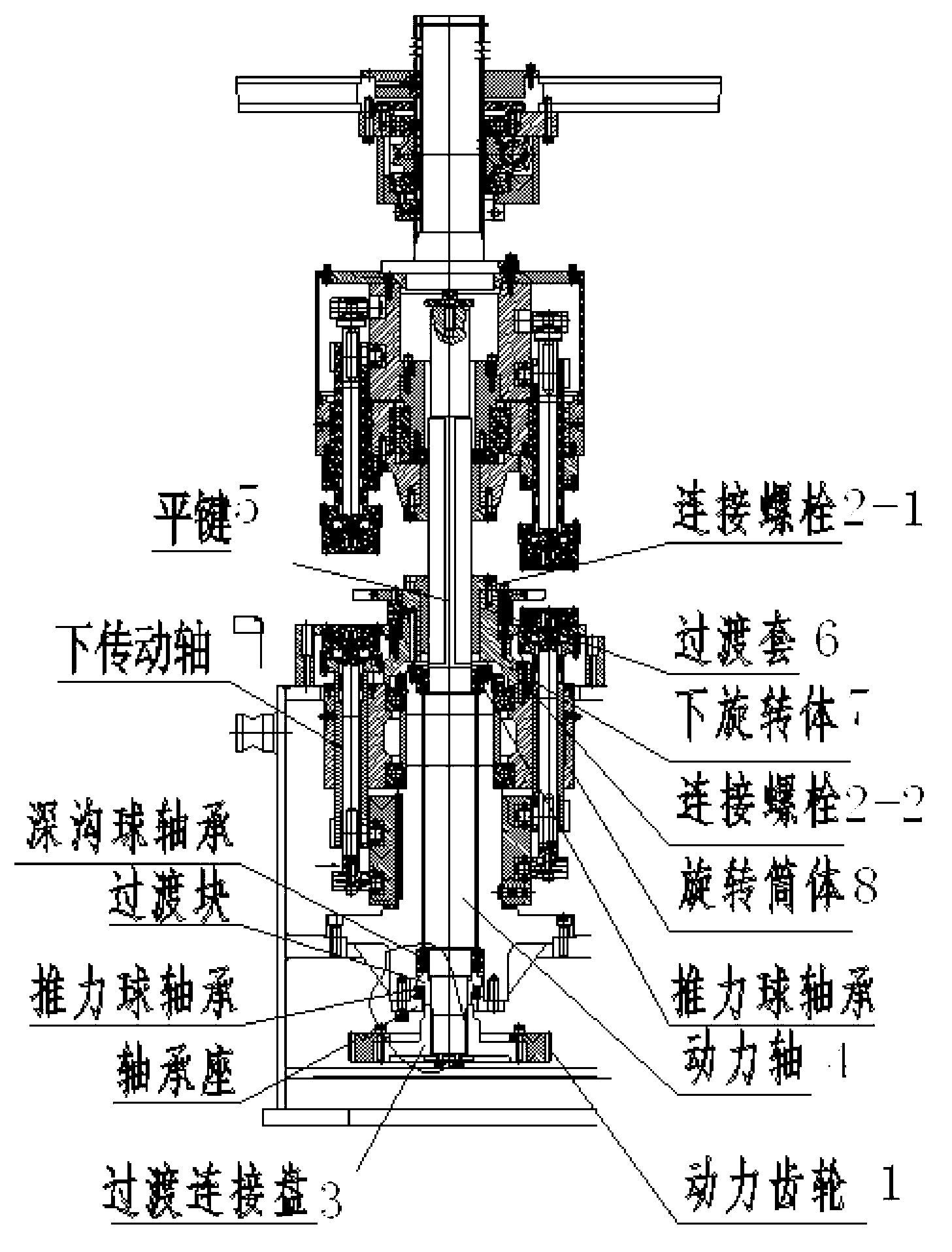

[0017] Such as image 3 As shown, the present invention provides a new type of transmission device for a combination machine, including a power gear (1), a connecting bolt (2), a transition connection plate (3), a power shaft (4), a flat key (5), a transition sleeve ( 6), the lower rotating body (7), the rotating cylinder (8), the lower transmission shaft (9) and the spline (10), wherein the connecting bolts (2) include the first connecting bolts (2-1) and The second connection bolt (2-2), the power gear (1) receives the power of the transmission device, and is connected with the transition connection plate (3) through the connection bolt (2), and the transition connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com