Connecting rod big-end hole turning clamp

A technology of large head holes and fixtures, applied in the directions of clamping, manufacturing tools, supports, etc., can solve problems such as low work efficiency, and achieve the effect of improving work efficiency, improving work efficiency, and shortening clamping and disassembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

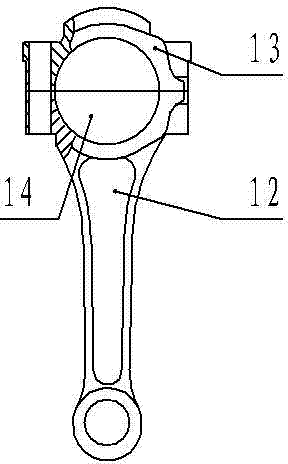

[0016] Such as figure 1 Shown is the connecting rod that needs to be clamped and positioned in this embodiment, including the connecting rod body 12 and the cover body 13. After the connecting rod body 12 and the cover body 13 are combined, there is a big hole 14, which is the hole that needs to be processed.

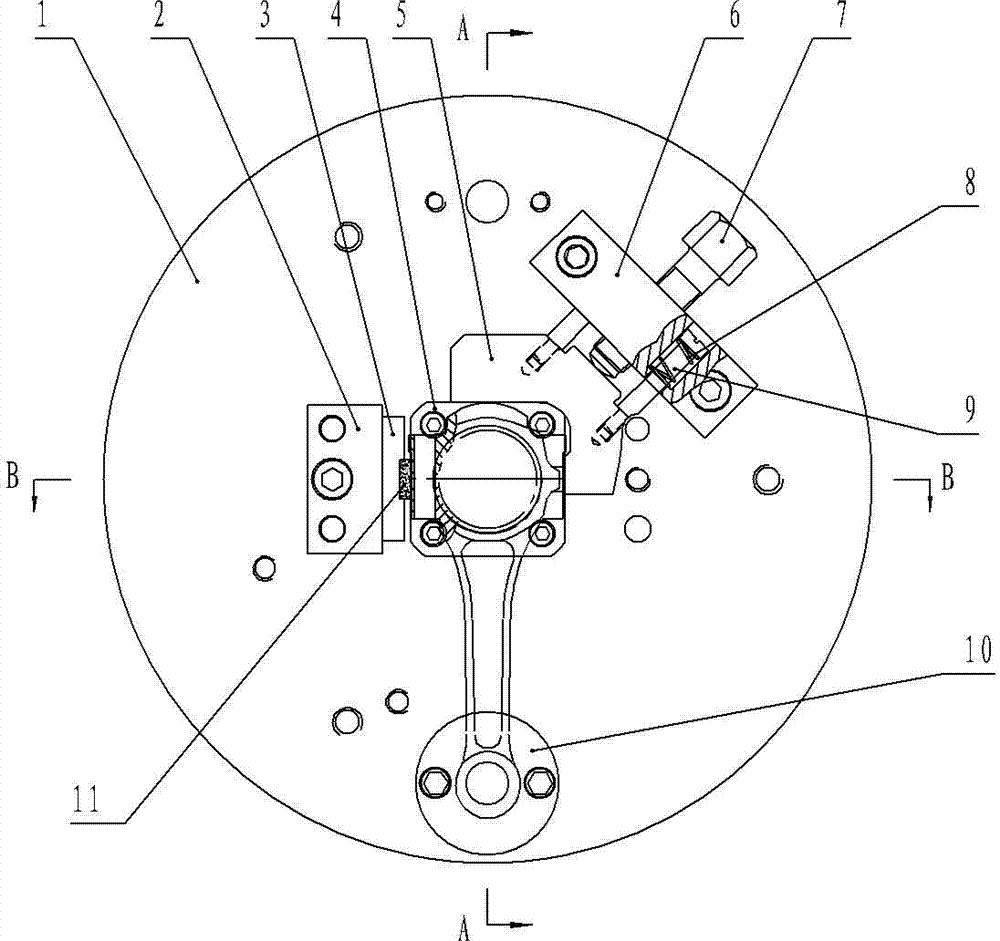

[0017] Such as figure 2 , image 3 , Figure 4 The big head hole clamp for connecting rods shown in the figure includes a clamp body 1 equipped with a small head positioning pin 10 and a big end support block 4, and the clamp body 1 is equipped with a side positioning block 3 and a side clamp on the periphery of the big end support block 4, respectively. A tightening device, an alloy spacer 11 is inlaid on the end surface of the side positioning block 3 near the big head support block 4, and the side positioning block 3 is installed on the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com