Dual metal saw blade

A bimetallic and saw blade technology, applied in the field of improving the cutting structure of metal cutting tools, to achieve the effects of fast heat dissipation, enlarged outer diameter, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

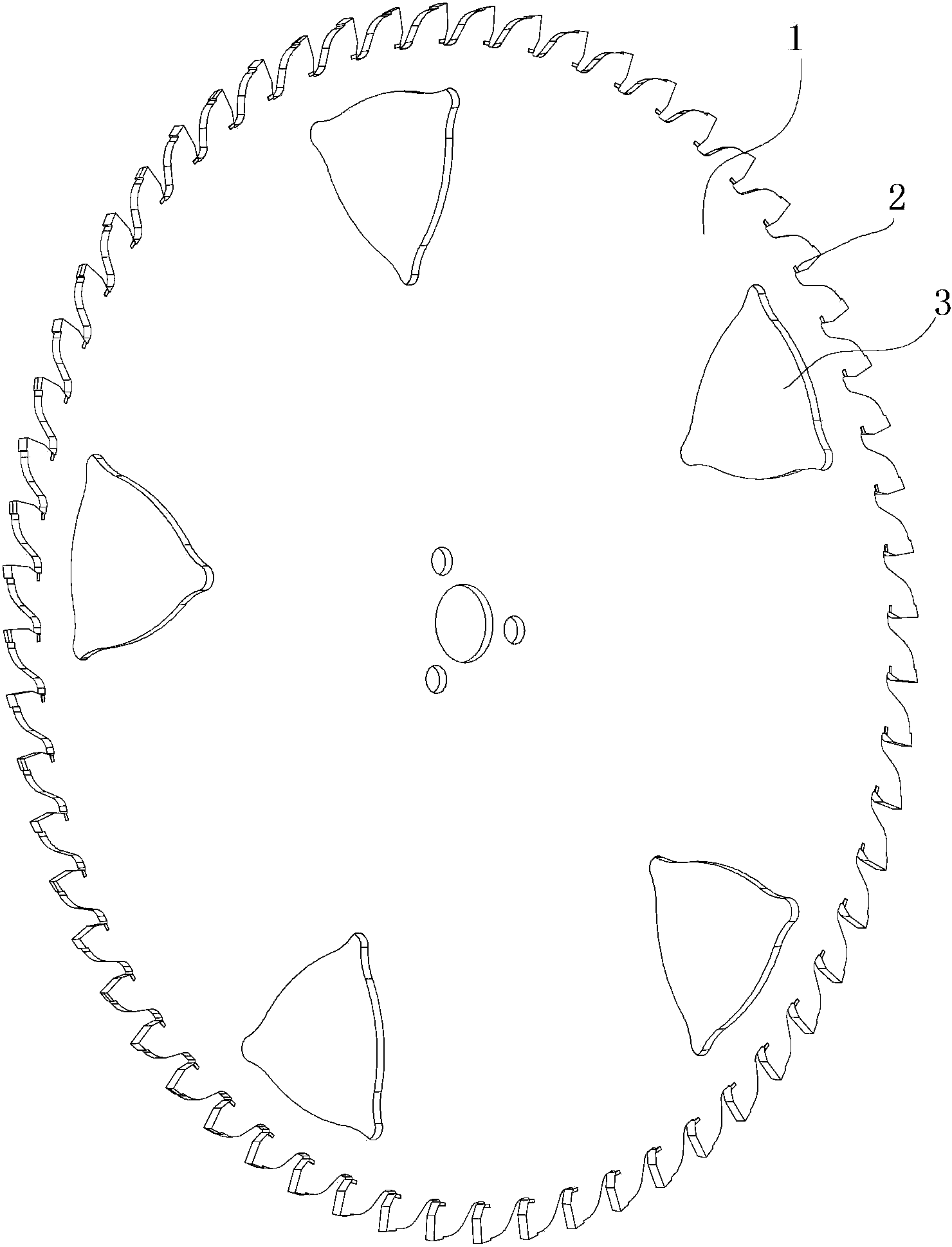

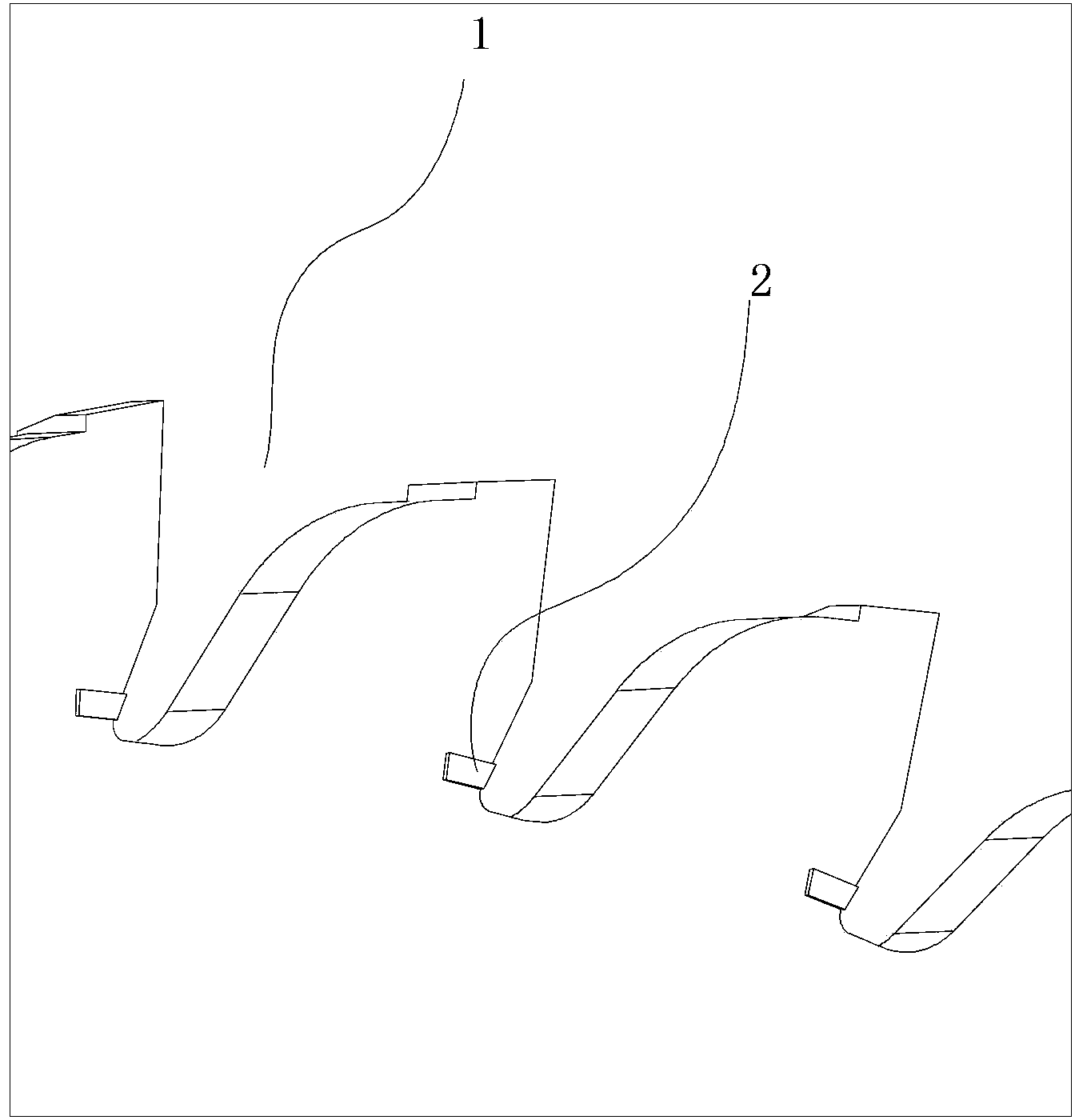

[0015] As shown in the figure, a bimetallic saw blade includes a first saw blade 1 that is arranged concentrically and rotates in the forward direction and a second saw blade that rotates in the reverse direction, wherein the first saw blade 1 is The saw blade of the long-toothed cutter head is distributed on the outside, and the second saw blade is the saw blade of the short-toothed cutter head, which is distributed on the inside. The key point of its invention is: the first saw blade 1 or the second saw blade On the opposite side, there is a 0.05-0.15 mm protruding friction bump 2 near the root of the saw blade head to prevent iron filings from entering the space between the two saw blades and causing deformation; the friction bump 2 is set on the inside of the first saw blade 1 Side: the friction bump 2 has a width in the range of 0.4-0.6 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com