Image module and manufacturing method thereof

A manufacturing method and image technology, applied in radiation control devices and other directions, to achieve the effect of reducing bad wear and tear and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a further understanding of the purpose of the present invention, structure, feature, and function thereof, now cooperate embodiment to describe in detail as follows:

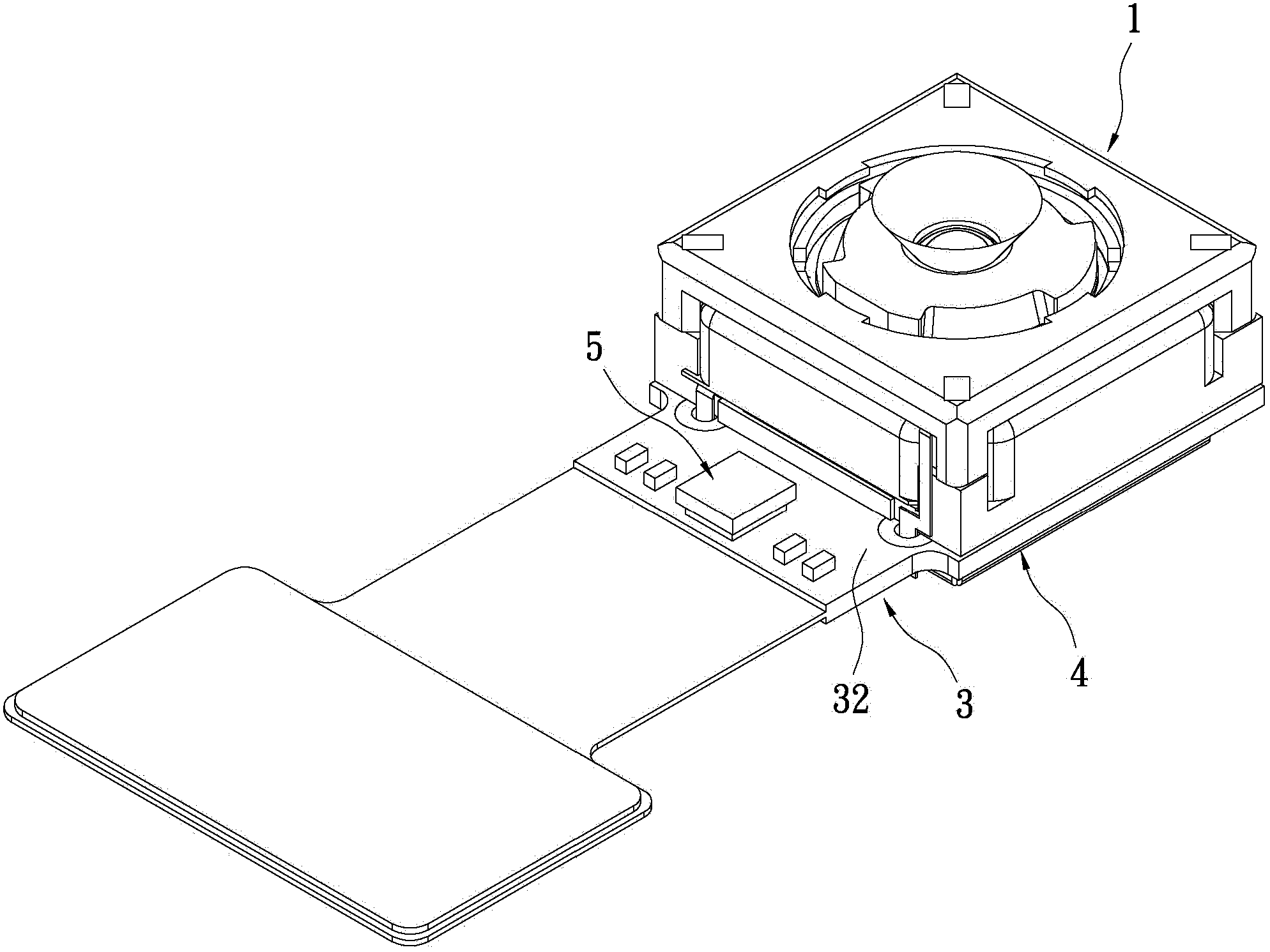

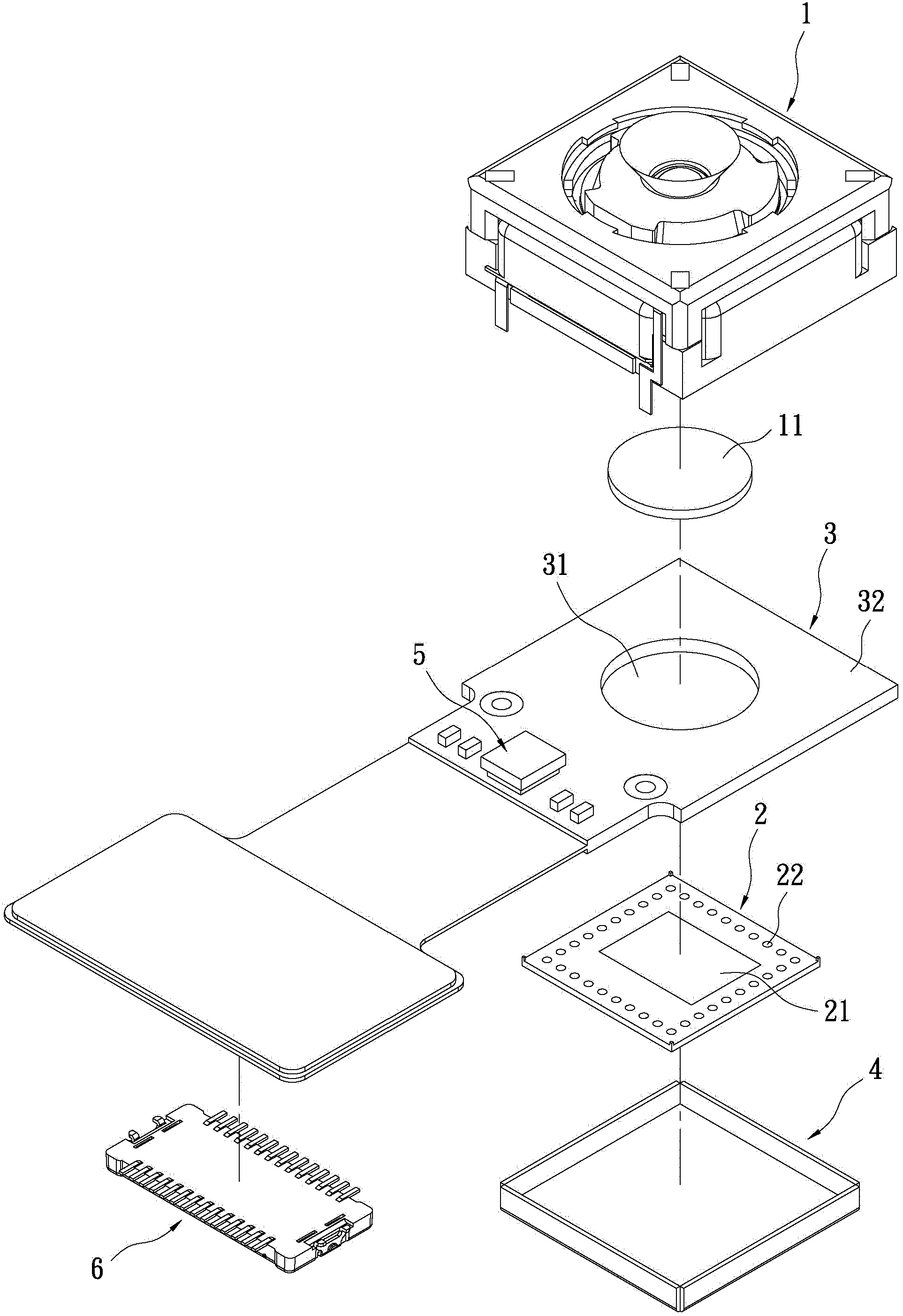

[0041] see figure 1 , and see Figure 2A and Figure 2B . The image module of the present invention includes a lens assembly 1 , an image sensing element 2 , a circuit board 3 , a packaging case 4 , a passive element 5 , and a control element 6 .

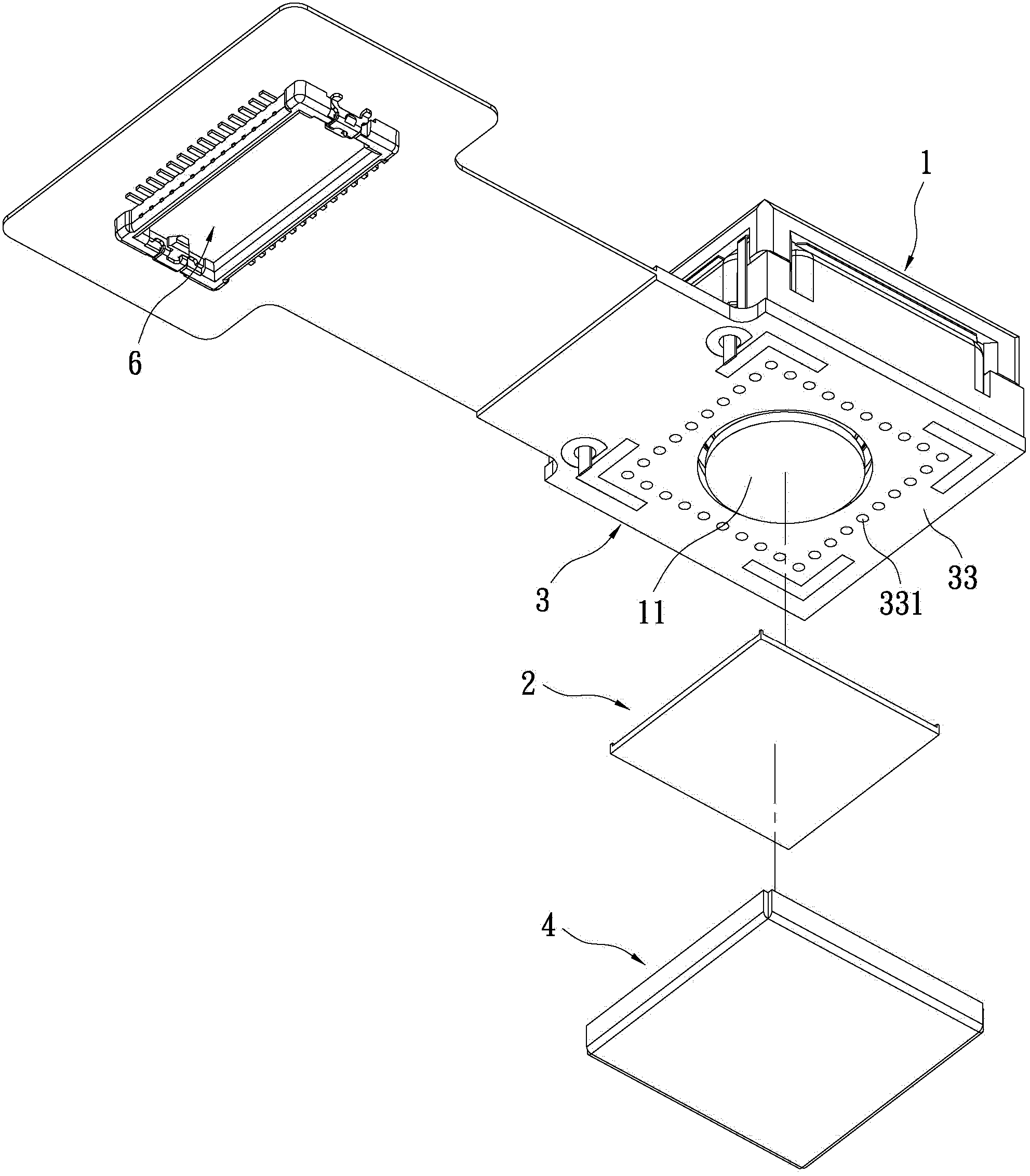

[0042] The circuit board 3 has an opening 31 , a first board surface 32 , and a second board surface 33 . The image sensing element 2 is disposed on the second plate surface 33 and corresponds to the opening 31. Specifically, the image sensing element 2 is an unpackaged sensing chip (Sensor Die) with a sensing region 21, the sensing region 21 corresponds to the opening 31 of the circuit board 3 .

[0043] The lens assembly 1 is mounted on the first board surface 32 and corresponds to the opening 31 . The lens assembly 1 further includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com