Process spray nozzle for chip developing process

A nozzle and process technology, applied in the field of process nozzles of chip development process, can solve the problems of extended stroke pressure loss, uneven distribution of runner pressure, inconsistent flow of outflow fluid, etc., achieving small impact, solving uneven flow distribution, Even pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

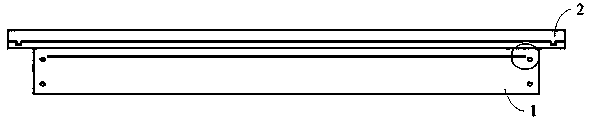

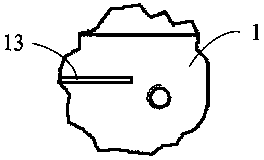

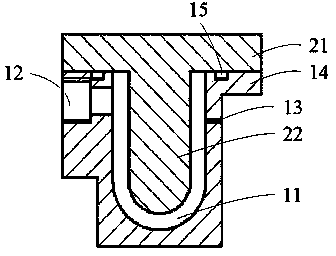

[0022] refer to Figure 1-6 , shows the embodiment 1 of the process nozzle used in the chip development process of the present invention, the process nozzle includes a nozzle body 1 and a baffle 2 .

[0023] The nozzle body 1 mainly includes a main chamber 11 , a developer inlet 12 , a developer outlet 13 and a fixing flange 14 . The main chamber 11 is U-shaped, and the developer solution inlet 12 and the developer solution outlet 13 are respectively located on two sides of the main chamber 11 and communicated with the main chamber 11 . In order to facilitate the rapid input of the developer, the developer inlet 12 can be connected to a quick connector, and the quick connector outputs the developer to the developer inlet 12 . The developer outlet 13 is a long straight slit, which is consistent with the main chamber 11 in the length direction, that is, viewed from the width direction of the main chamber 11, the two ends of the slit are aligned with the two ends of the main cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com