Large-core-diameter bend insensitive energy transmitting optical fiber

A bending-insensitive, energy-transmitting optical fiber technology, which is applied in the direction of multi-layer core/cladding optical fiber, cladding optical fiber, graded index core/clad optical fiber, etc. Poor sensitive performance, fiber failure and other problems, to achieve good bending insensitivity, improve light collection and concentration capabilities, and low additional bending loss

Active Publication Date: 2013-12-25

YANGTZE OPTICAL FIBRE & CABLE CO LTD

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the Chinese patent CN102721998A adopts this method. This kind of energy-transmitting optical fiber can provide convenient and efficient coupling operation, but the disadvantage is that the cost of low-refractive index coating is relatively high, and under the same environmental conditions, when transmitting higher energy, the coating It is easy to generate heat, which will cause the softening or even burning of the low-refractive index coating, resulting in the failure of the fiber, and the bending insensitivity of the fiber with this structure is also poor

[0005] In addition, when the light is transmitted in the optical fiber, its beam quality factor M 2 The core diameter of the fiber changes exponentially, and after being transmitted through a fiber with a certain core diameter and numerical aperture, the beam quality factor M 2 The maximum value is related to the core diameter and numerical aperture angle of the fiber. When we use it, the fiber will inevitably be bent to varying degrees. When the fiber is subjected to large bending stress for a long time, the service life of the fiber will inevitably be shortened, and the transmission performance index It will also decrease. For this reason, the optical fiber is required to have certain bending characteristics to meet the needs of different occasions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

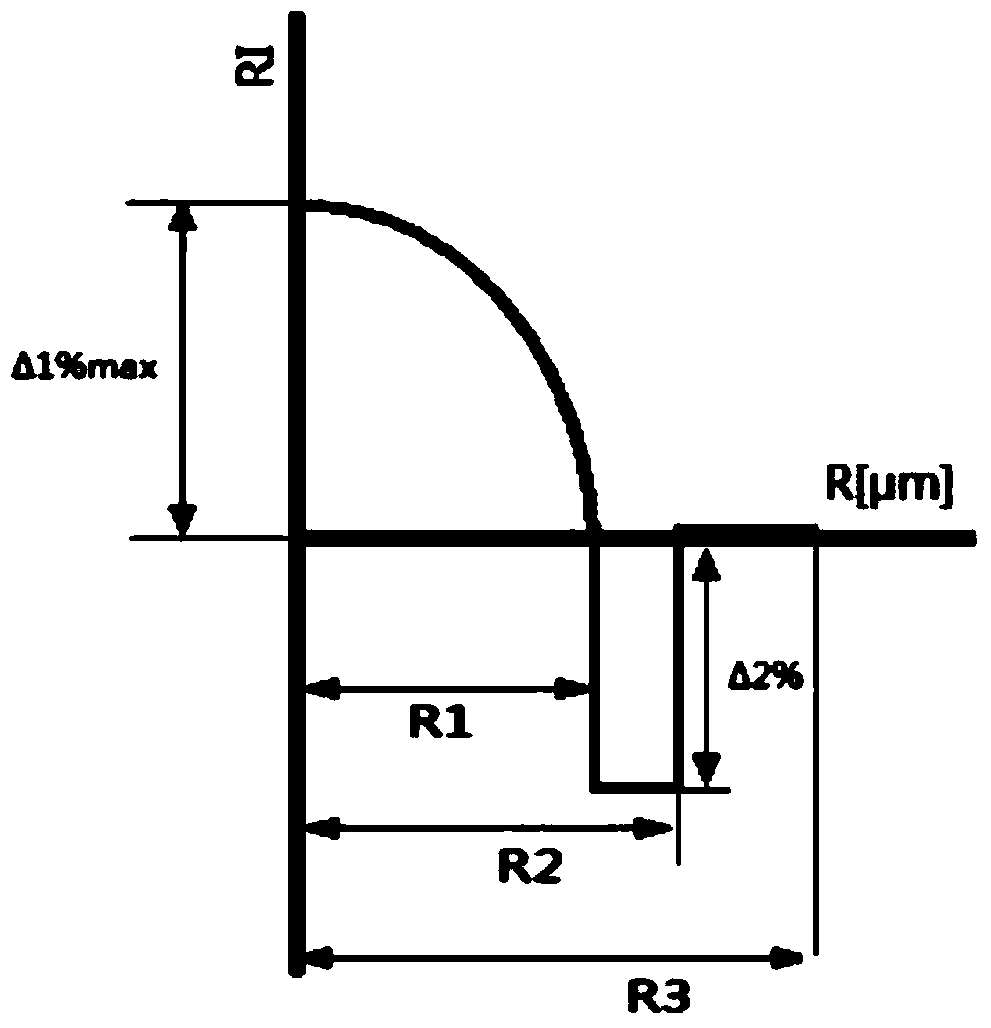

[0039] Detailed examples will be given below to further illustrate the present invention. In Table 1, R1 is the radius of the core layer, R2 is the radius of the inner cladding, R3 is the radius of the outer cladding, W1=R2 / R1, W2=R3 / R1. As shown in Table 1 below.

[0040] Table 1

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a large-core-diameter bend insensitive energy transmitting optical fiber. The large-core-diameter bend insensitive energy transmitting optical fiber comprises a core layer and cladding layers and is characterized in that the core layer is distributed according to a gradually-changing refractive index, the distribution power exponent alpha ranges from 1.8 to 2.1, the maximum value delta1%max of the relative refraction index difference of the core layer ranges from 1.0% to 2.5%, the radius R1 of the core layer ranges from 95 micrometers to 500 micrometers, the inner cladding layer and the outer cladding layer are sequentially arranged on the core layer from inside to outside, the relative refraction index difference delta2% of the inner cladding layer ranges from -0.6% to -1.3%, the specific value of the radius of the inner cladding layer to the radius of the core layer satisfies the equation that w1=R2 / R1 and ranges from 1.05 to 1.2, the outer cladding layer is a pure quartz glass layer, and the specific value of the radius of the outer cladding layer to the radius of the core layer satisfies the equation that w2=R3 / R1 and ranges from 1.1 to 1.4. According to the large-core-diameter bend insensitive energy transmitting optical fiber, the light receiving capacity and the light condensation capacity of the optical fiber can be remarkably improved, the optical fiber has good transmission efficiency and can bear high-energy laser transmission, the design of the profile with the gradually-change refractive index is adopted for the core layer, and therefore the optical fiber has the self-focusing effect and has more advantages in practical application such as laser processing.

Description

technical field [0001] The invention relates to a bending-insensitive energy-transfer optical fiber with a large core diameter. The optical fiber can carry high-energy laser transmission, has good bending insensitivity and excellent transmission efficiency, and belongs to the technical field of optical fiber energy transmission. Background technique [0002] The large core diameter multimode energy transmission fiber can flexibly and safely transmit high laser energy in a three-dimensional complex space, and can transmit high-power laser to a specific position, simplifying the optical path system and improving the flexibility of the laser system application work platform Function, has been widely used in military, laser processing, medical, sensing, lighting and many other fields. [0003] In the prior art, conventional large-core energy-transmitting optical fibers are mainly divided into two structures, one is a step-type refractive index profile structure, and the other is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/036G02B6/028

Inventor 汪松郑伟赵亮刘海华徐进禹雷

Owner YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com