Rotary body combined seal device

A combined seal and rotary body technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as reduced reduction rate, large gap between sealing surfaces, and unreliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

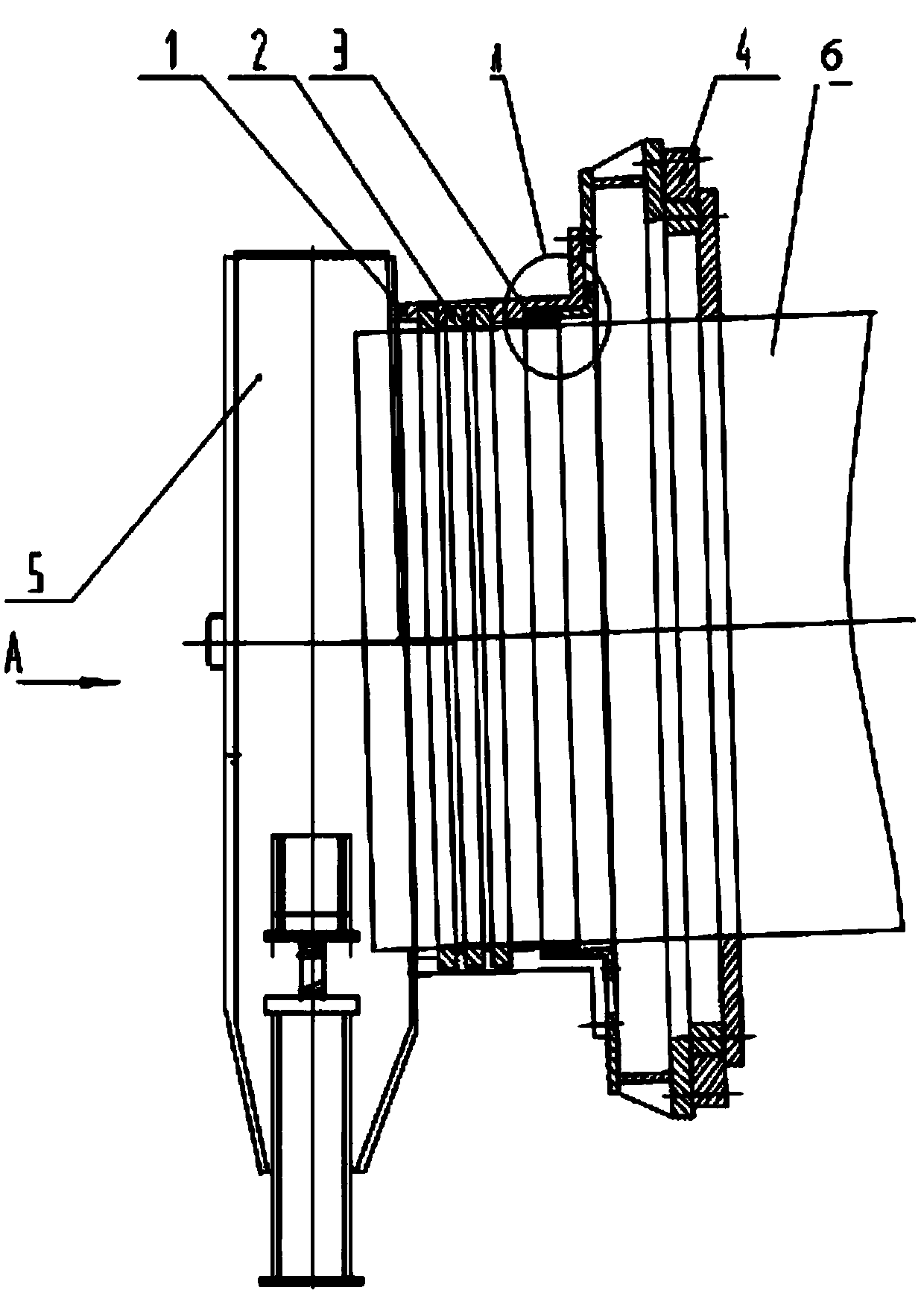

[0018] A rotary body combined sealing device of the present invention comprises:

[0019] Rotary cylinder 6,

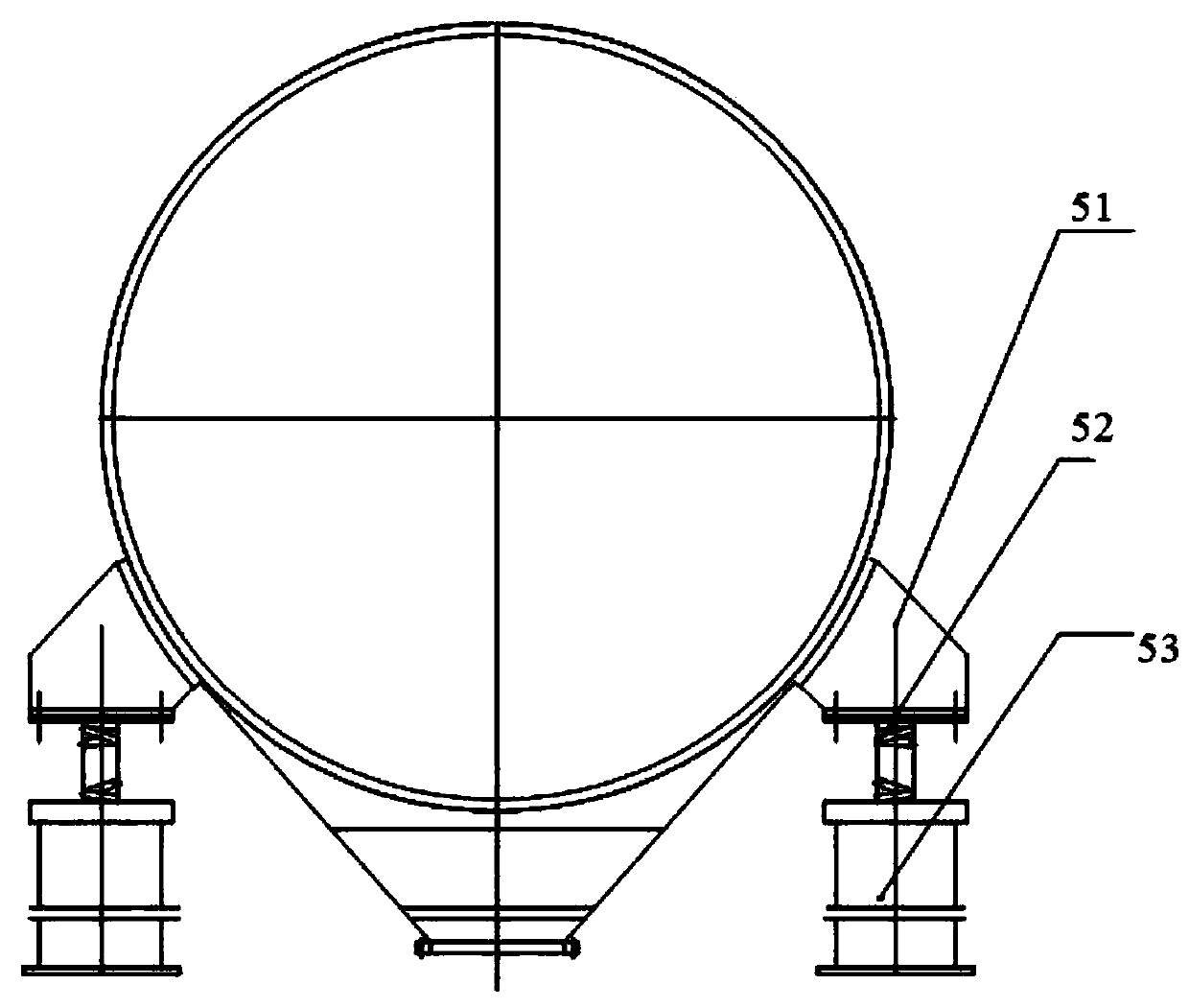

[0020] The elastic material cover 5 adopts the form of elastic floating, and the cover is arranged at one end of the rotating cylinder 6 to eliminate or reduce the interference effect on the V-shaped fabric rubber sealing ring due to the radial runout of the rotating cylinder 6 .

[0021] The sealing cylinder 1 has an L-shaped cross section, one end is welded on the elastic material cover 5, and the other end is sleeved on the periphery of the rotating cylinder 6, including a horizontal part and a vertical part,

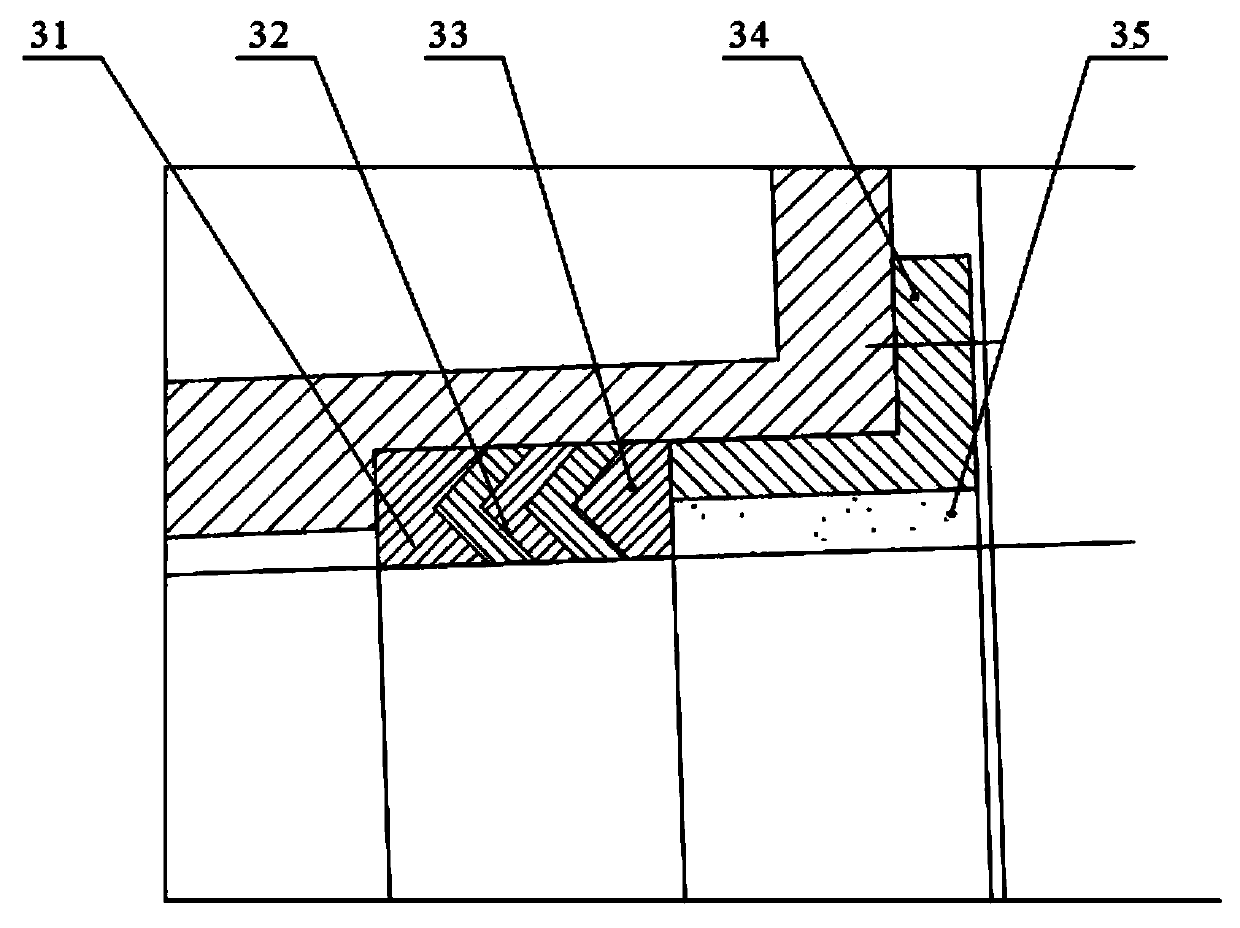

[0022] The sealing device adopts the multi-channel sealing combination form of packing 2, V-shaped fabric rubber sealing ring 3 and sealing coupling part 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com