Powder metallurgy brake lining for CRH5 (China railway high-speed) motor train unit

A technology of powder metallurgy and EMUs, applied in the field of brake pads, can solve problems such as increased material wear, inability to ensure uniform diffusion of heat energy, thermal cracks on the surface of brake pads, etc., to prevent rotation and loosening, complete reliability of braking performance, and reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

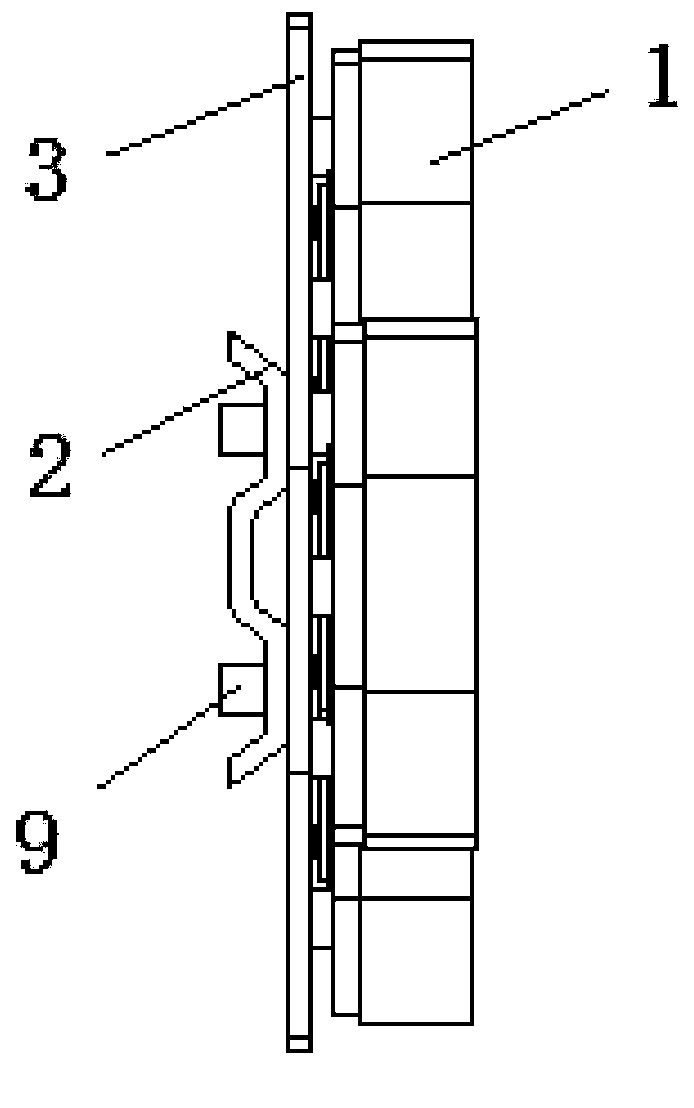

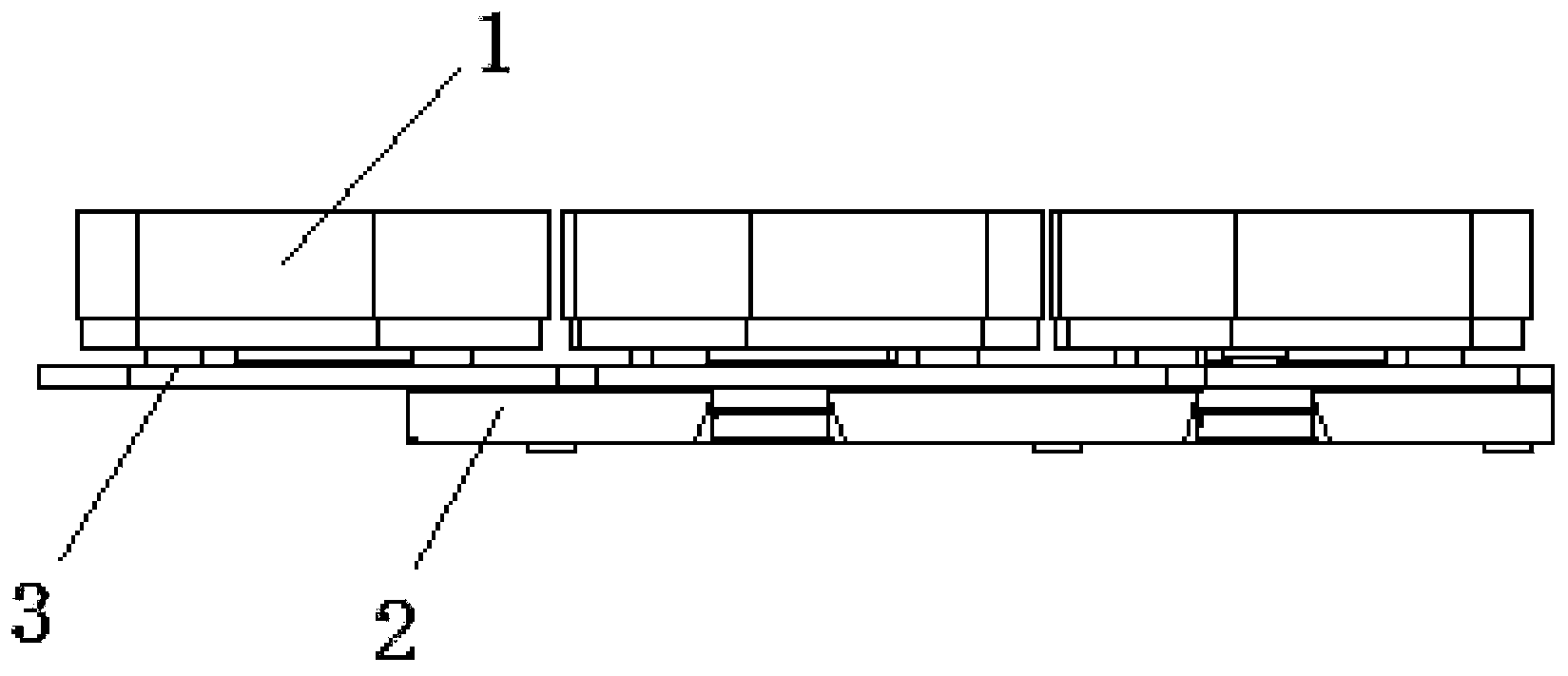

[0026] Such as Figure 1 to Figure 7 As shown, the present invention includes 5 brake pad friction bodies 1, a dovetail block 2, a steel back plate 3, 5 rivets 4, 5 large gaskets 5, 5 small gaskets 6, and 5 butterfly shrapnel 7 , 15 cotter pins 8 and 6 flat head rivets 9.

[0027] Such as Figure 5 , Figure 8 , Figure 9 As shown, five brake pad friction bodies 1 of the present invention are fastened to the front of the steel back plate 3, and each brake pad friction body 1 includes an equilateral triangular friction body skeleton 11 with three arc-shaped chamfers, And a friction body 12 arranged on the upper surface of the friction body skeleton 11 and having the same shape as the friction body skeleton 11 . The center of the friction body frame 11 is provided with a step hole 13, and a guide hole 14 is provided on the three arc-shaped chamfers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com