A diesel engine pressure detection signal integrated input and output device

A detection signal, input and output technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of high installation and maintenance costs, weak detection signals, and increased costs, and achieve simple installation and maintenance. Accuracy and stability, the effect of high precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be described in detail below in conjunction with accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments, and all equivalent changes and modifications made according to the contents of this description belong to the patent application of the present invention scope of protection.

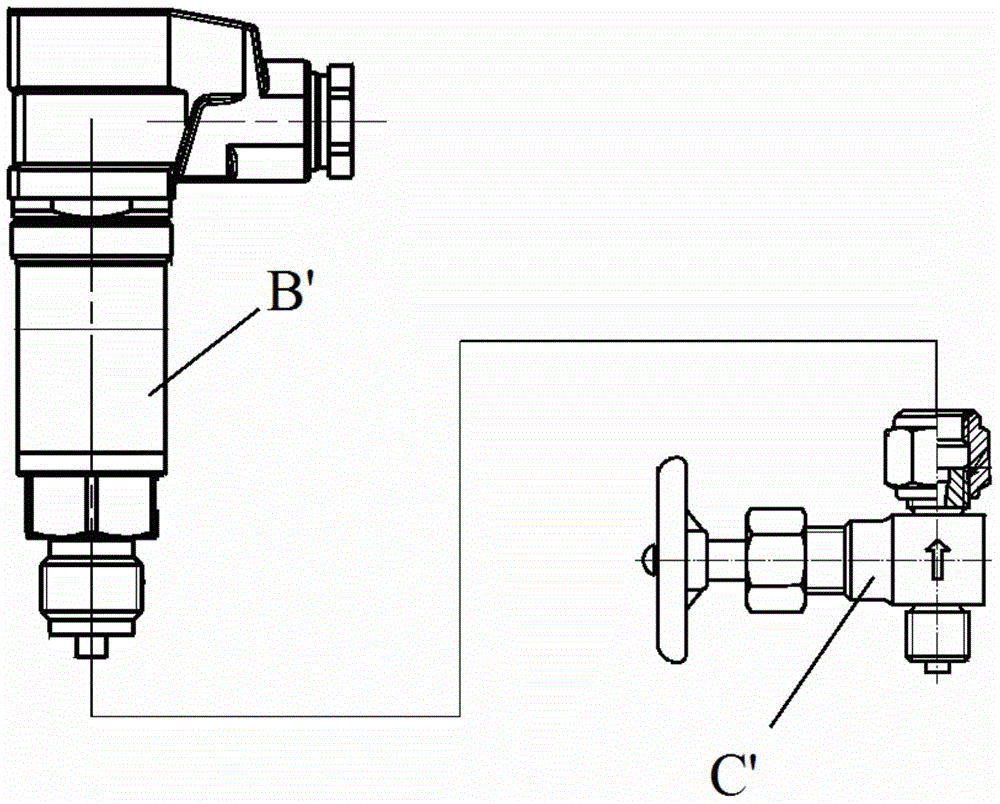

[0042] see figure 2 , the diesel engine pressure detection signal integration input and output device shown in the figure is installed on the diesel engine, such as a marine diesel engine at a position where the rear end is easy to operate and has low vibration, so as to prevent adverse effects caused by vibration. The diesel engine pressure detection signal integrated input and output device includes an integrated operation panel 1, several signal input detection assemblies, an intermediate junction box D, a manipulation detection tube 6 and a cable 4, and the intermediate junctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com