Mixer scrubbers and mixer scrubber systems for dusty gases

The technology of a washing device and a mixer is applied in the field of coal chemical industry, which can solve the problem of difficulty in efficiently separating high-ash content gas, and achieve the effects of good particle separation, good gas purification, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

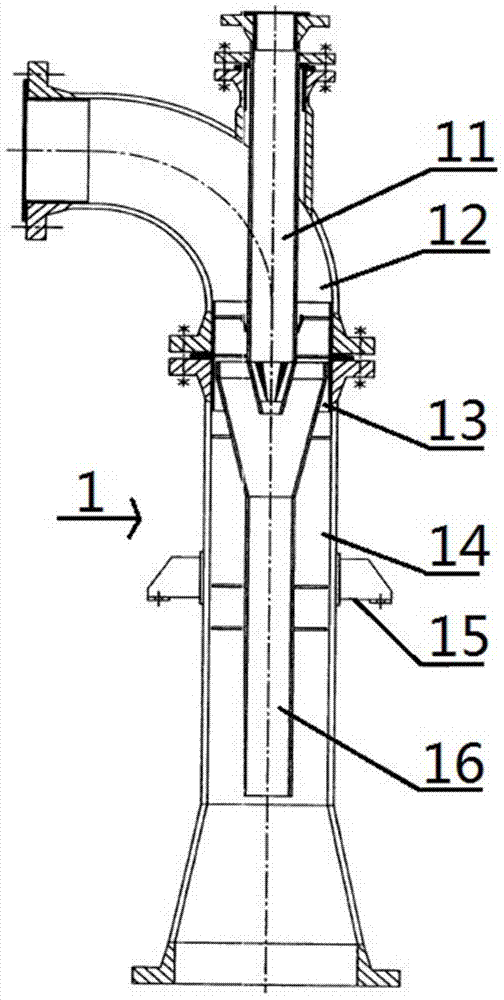

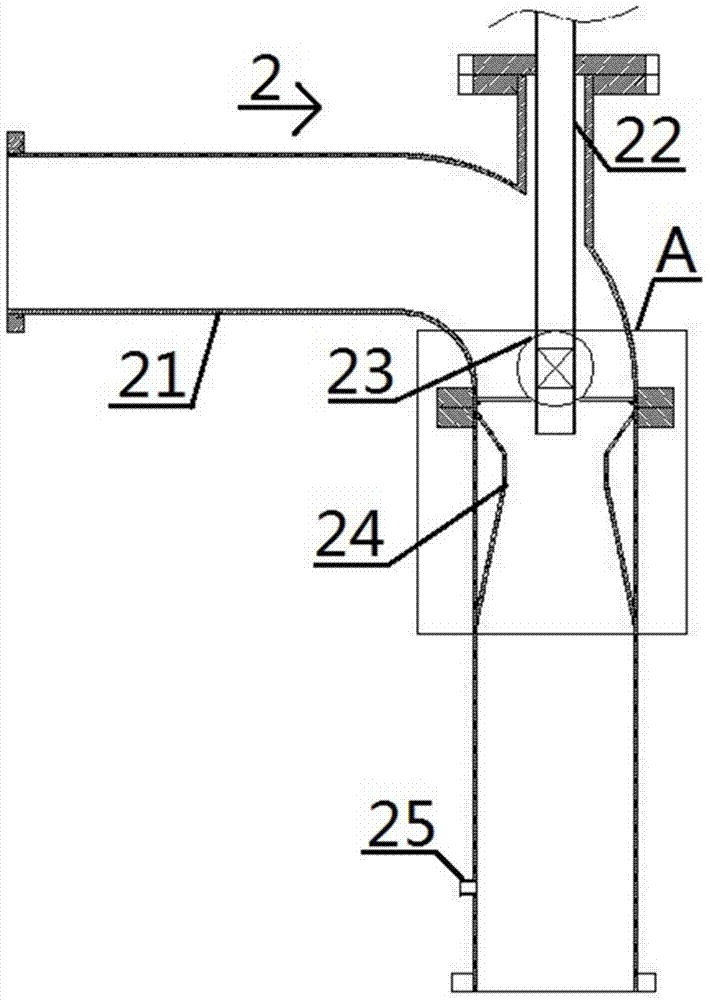

[0031] The structure of the mixer scrubber of the dusty gas of the present embodiment is as follows:

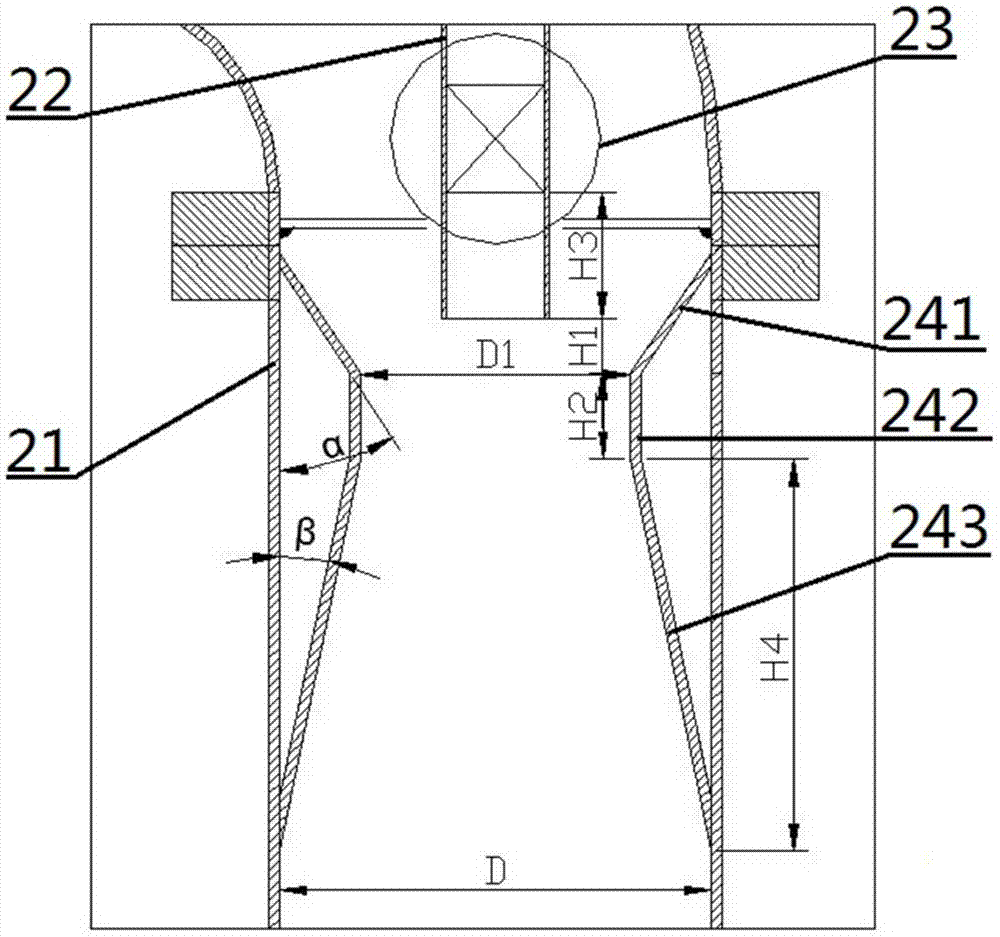

[0032] Please combine Figure 2-3 It should be understood that the mixer scrubber 2 of the dusty gas of the present embodiment comprises a synthesis gas pipe 21 and a gray water pipe 22, the water spray port of the gray water pipe 22 communicates with the synthesis gas pipe 21, and the synthesis gas pipe 21 is provided with There is a sleeve pipe 24, the water spray port of the gray water pipe 22 is opposite to the air inlet of the sleeve pipe 24, and a swirler 23 is arranged near the water spray port of the gray water pipe 22. The diameter of the synthesis gas pipe 21 is D, and the size of the diameter D is 464 mm. During actual production, according to the difference in the operating load of the gasifier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com