The preparation method of anhydrous ampicillin

A technology for ampicillin and ampicillin trihydrate, which is applied in the field of preparation of anhydrous ampicillin, can solve the problems affecting the quality and safety of anhydrous ampicillin as a pharmaceutical intermediate, easily exceeding the standard of heavy metal ions, and accumulating clutter on the production site, etc. Achieve the effect of being conducive to sub-packaging, fast salt formation, and regular production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

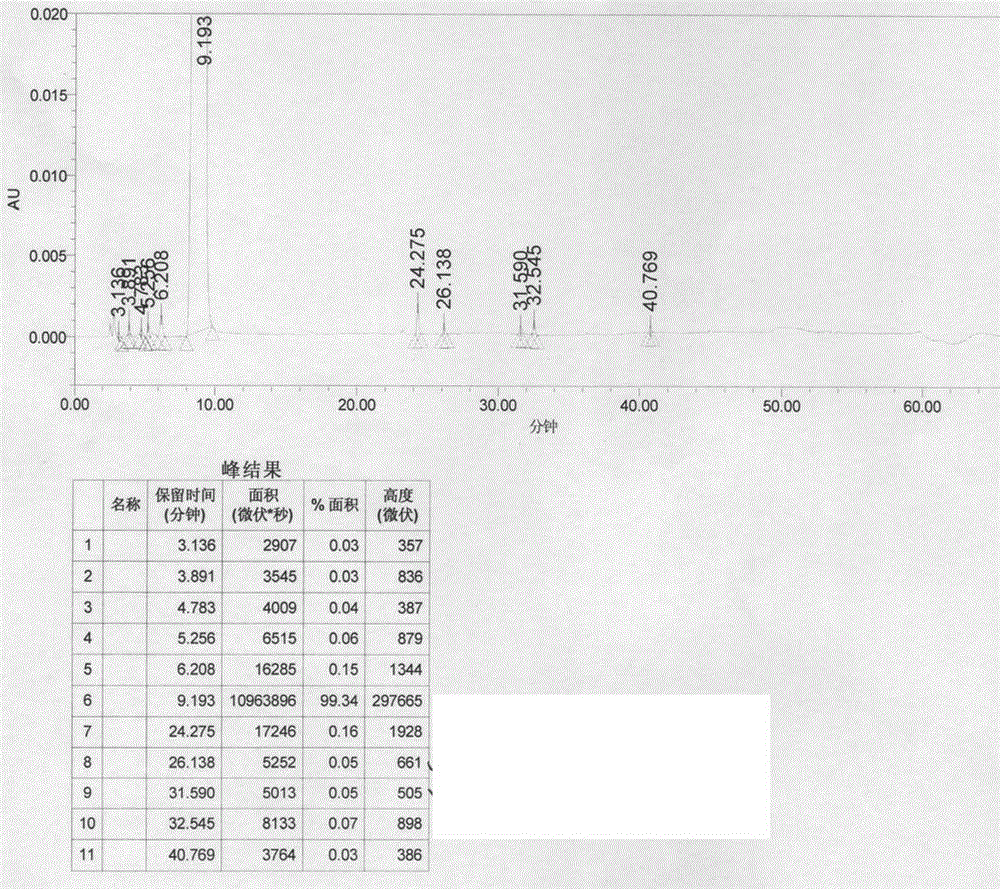

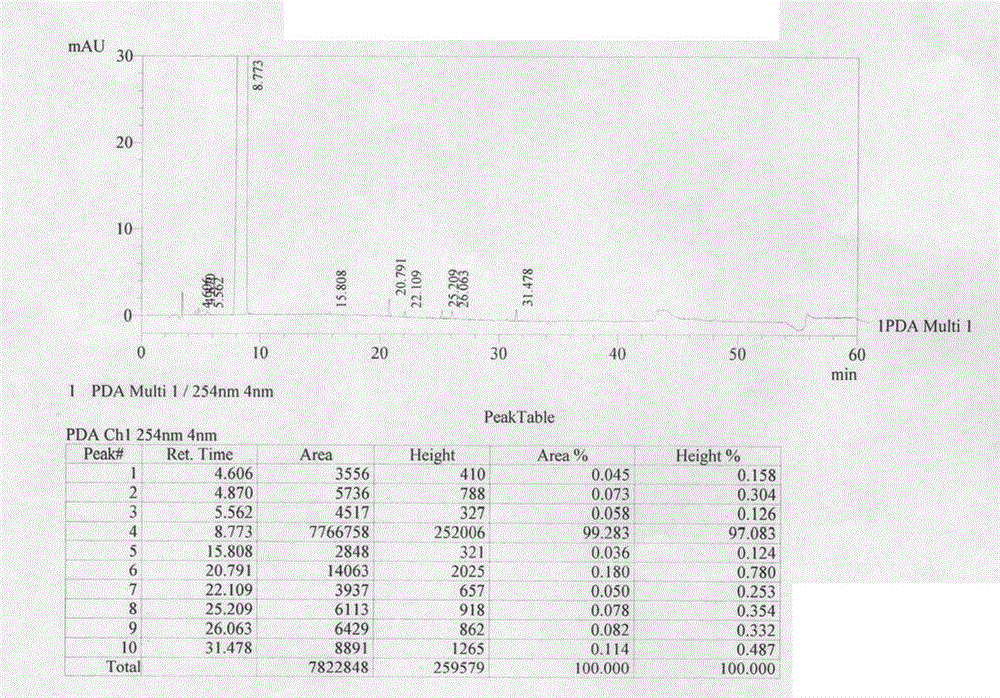

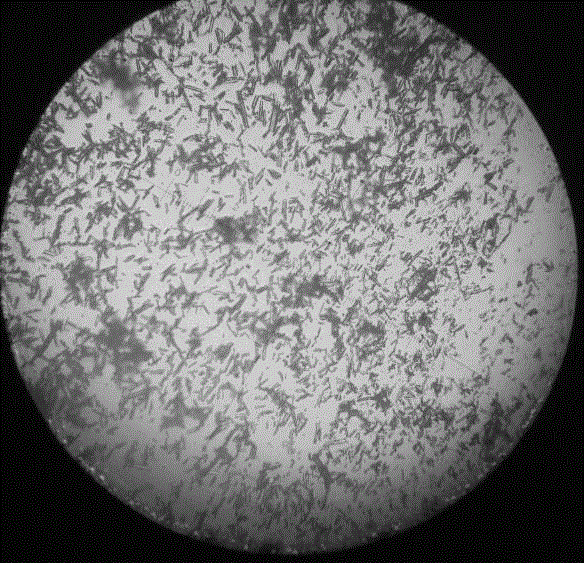

Image

Examples

Embodiment 1

[0019] The preparation method of anhydrous ampicillin is as follows:

[0020] 1. Add 300 kg of ampicillin trihydrate and stir in the enamel tank, then add 1000 L of reclaimed isopropanol (water content 13wt%) and mix;

[0021] ②The above-mentioned enamel tank was heated to 50°C in a water bath, heated to reflux and stirred for 40 minutes; cooled to room temperature with cold water, and centrifuged; soaked and washed the solid obtained by centrifugation with acetone for about 3 minutes, and continued to centrifuge and compact;

[0022] ③Hollow drying for 40-60 minutes, the temperature is controlled at 45-50°C, the vacuum degree is <-0.075MPa, and it is turned 1-2 times during the period.

Embodiment 2

[0024] The basic process is the same as in Example 1, except that the water bath is heated to 55° C. in the second step.

Embodiment 3

[0026] The basic process is the same as in Example 1, except that the water bath is heated to 60° C. in the second step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com