Method for producing full-water-soluble monoammonium phosphate by phosphoric acid by wet process

A wet-process phosphoric acid and monoammonium phosphate technology, which is applied to ammonium orthophosphate fertilizers, phosphates, phosphorus oxyacids, etc., can solve the problems of high production cost of water-soluble monoammonium phosphate, unfavorable promotion of drip irrigation and fertilization, etc., and achieve product quality Good, cost saving, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

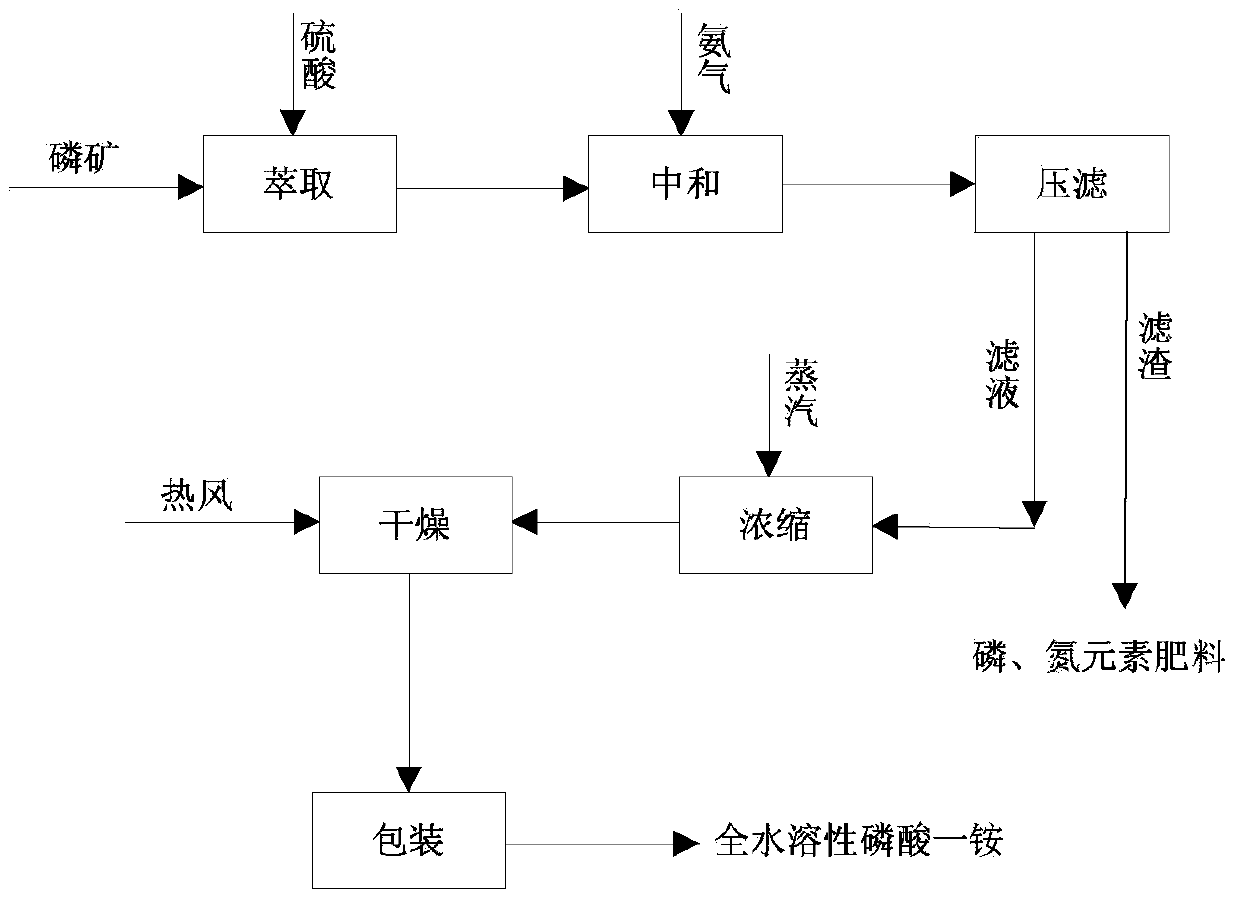

[0025] Such as figure 1 The technological process shown, phosphate rock slurry and sulfuric acid extraction to produce wet-process phosphoric acid, the main technical indicators of the obtained desulfurized phosphoric acid are: P 2 o 5 Concentration 18.5%, SO 3 Concentration 0.65%, F concentration 1.5%. The obtained desulfurized phosphoric acid is neutralized with gaseous ammonia in the ammonia neutralization reactor. After the reaction is completed, the end point of the neutralized slurry is PH=4.0, and the filter press performs liquid-solid separation of the neutralized slurry to obtain a solid phase slag And filtrate, the solid phase slag water content is 15-40%, and the solid phase slag (filter residue) is used for the production of ordinary phosphorus and nitrogen element fertilizers. Concentrate the filtrate from the press filtration of the neutralized slurry to a density of 1.42 / cm 3 Fully water-soluble monoammonium phosphate slurry. The concentrated fully water-so...

Embodiment 2

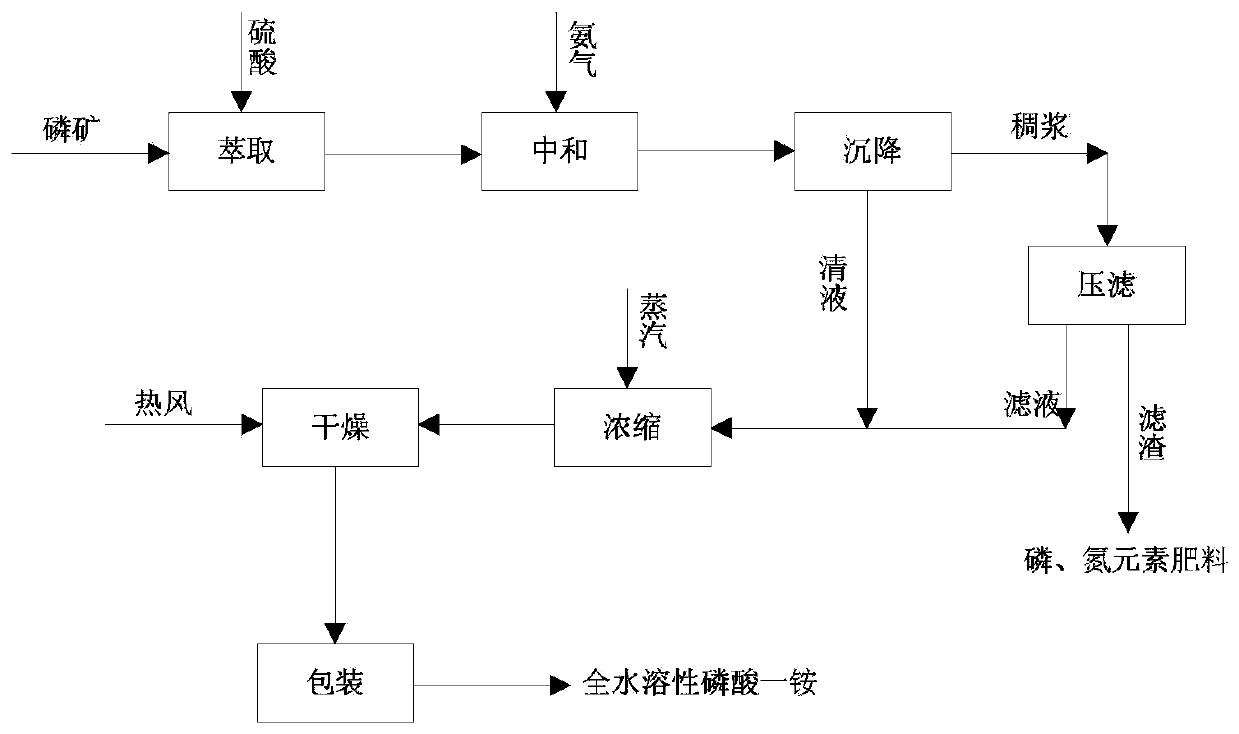

[0027] Such as figure 2 The technological process shown, phosphate rock slurry and sulfuric acid extraction to produce wet-process phosphoric acid, the main technical indicators of the obtained desulfurized phosphoric acid are: P 2 o 5 Concentration 21.2%, SO 3 Concentration 0.7%, F concentration 1.7%. The obtained desulfurized phosphoric acid is neutralized with gaseous ammonia in the ammonia neutralization reactor, and the pH of the end point of the neutralized slurry is 4.2 after the reaction is completed. The solid-liquid separation is carried out by adopting the method of sedimentation separation first, followed by pressure filtration treatment, to obtain solid-phase slag and filtrate, the water content of the solid-phase slag is 15-40%, and the solid-phase slag is used for the production of ordinary phosphorus and nitrogen element fertilizers. Concentrate the filtrate from the press filtration of the neutralized slurry to a density of 1.43g / cm 3 Fully water-soluble ...

Embodiment 3

[0029] Such as figure 2 The technological process shown, phosphate rock slurry and sulfuric acid extraction to produce wet-process phosphoric acid, the main technical indicators of the obtained desulfurized phosphoric acid are: P 2 o 5 Concentration 25.5%, SO 3 Concentration 0.8%, F concentration 1.85%. The obtained desulfurized phosphoric acid is neutralized with gaseous ammonia in the ammonia neutralization reactor, and after the reaction is completed, the pH of the end point of the neutralized slurry is 3.8. The solid-liquid separation is carried out by adopting the method of sedimentation separation first, followed by pressure filtration treatment, to obtain solid-phase slag and filtrate, the water content of the solid-phase slag is 15-40%, and the solid-phase slag is used for the production of ordinary phosphorus and nitrogen element fertilizers. Concentrate the filtrate from the press filtration of the neutralized slurry to a density of 1.39g / cm 3 Fully water-solubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com