Steel coil sheath with diameter-changing mechanism

A sheath and steel coil technology, applied in the field of machinery, can solve the problems of unreliable fixing and easy falling, and achieve the effects of reducing friction, avoiding scratches and alleviating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

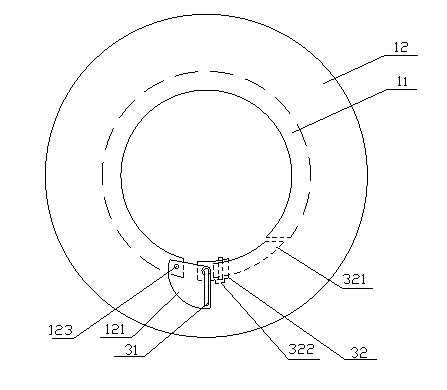

[0031] Embodiment 1: see Figure 1-5, a steel coil sheath with a diameter reducing mechanism, comprising a circular sleeve 11 and a hollow disc base 12, the inner diameters of the circular sleeve and the hollow disc base are equal and connected into a whole body, the steel coil sheath It also includes a diameter-reducing mechanism, which includes a threaded rod 314 inserted into the through hole 112 with a 90-degree handle 31, and the handle is provided with a positioning pin 311; the 90-degree handle adopts a 90-degree shape. The reason is that the operator can hold the handle with his hand to operate the variable diameter mechanism. The operation is smooth and labor-saving. The second function is that the 90-degree handle is parallel to the base surface of the steel coil sheath disc, and can be positioned and stored in the sheath through the positioning pin on the handle. The fan-shaped groove on the base of the disc will not protrude outward, and will not be damaged by acci...

Embodiment 2

[0033] Embodiment 2: The specific process of inserting the diameter reducing mechanism into a steel coil larger than its diameter.

[0034] see Figure 4 , Figure 5 , the steel coil sheath circular sleeve 11 with a diameter-changing mechanism is inserted into the inner ring of the steel coil 2 that is larger than its diameter, and when it cannot be fixed stably, rotate the steel coil sheath 1 until the handle 31 of the threaded rod 314 is vertical At the ground position and the open hollow body 32 falls on the bottom of the inner ring of the steel coil 2. At this time, the sheath is lifted to make the sleeve 11 contact with the top of the inner ring of the steel coil 2, and then the handle 31 of the threaded rod 314 is removed from the inner ring of the sheath. The disc base 12 fan-shaped groove 121 positioning hole 122 is drawn out, the handle 31 is rotated clockwise, the hollow body 32 and the elastic wear-resistant rubber skin 321 fixed on the threaded rod 314 also rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com