Compact trash compactor

A garbage compressor, compact technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large installation distance of the whole machine, narrow compression equipment silo, unstable thrust, etc., to save land and civil construction costs, garbage silos Reasonable effect of increase and thrust direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

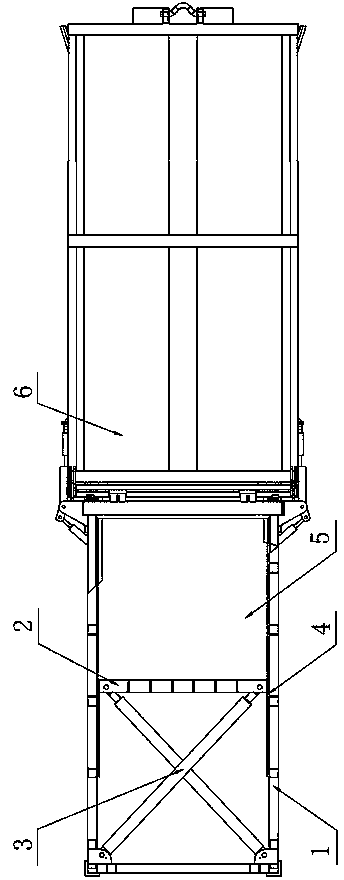

[0009] according to figure 1 A compact garbage compressor shown includes a compressor body 1, a pressure head 2, a pressure head guide rail 4, and a compression chamber 5. The pressure head 2 is directly powered by a cross cylinder 3 to make it advance along the pressure head guide rail 4 and moving in the backward direction, the cross oil, 3 is arranged on the left and right sides of the pressure head 2.

[0010] After using the cross cylinder 3, the installation distance of the pressure head 2 is reduced by half without changing the compression strength of the compression equipment, but the stroke distance of the pressure head 2 is increased by 30%, and the reciprocating speed is also increased; After the installation distance of the head 2 is reduced, the effectively saved space is applied to the garbage bin, which increases the size of the garbage bin and greatly improves the working efficiency of the compression equipment; due to the reasonable thrust direction, the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com