A three-dimensional numerical control wire-cut electric discharge machine tool

A technology of wire electric discharge and cutting machine tools, applied in the field of CNC wire cutting machine tools, which can solve problems such as three-dimensional modeling, complicated programming, large accumulative errors in clamping, and complicated workpieces in clamping, so as to reduce quality management costs and reduce defective products , The effect of low machine maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

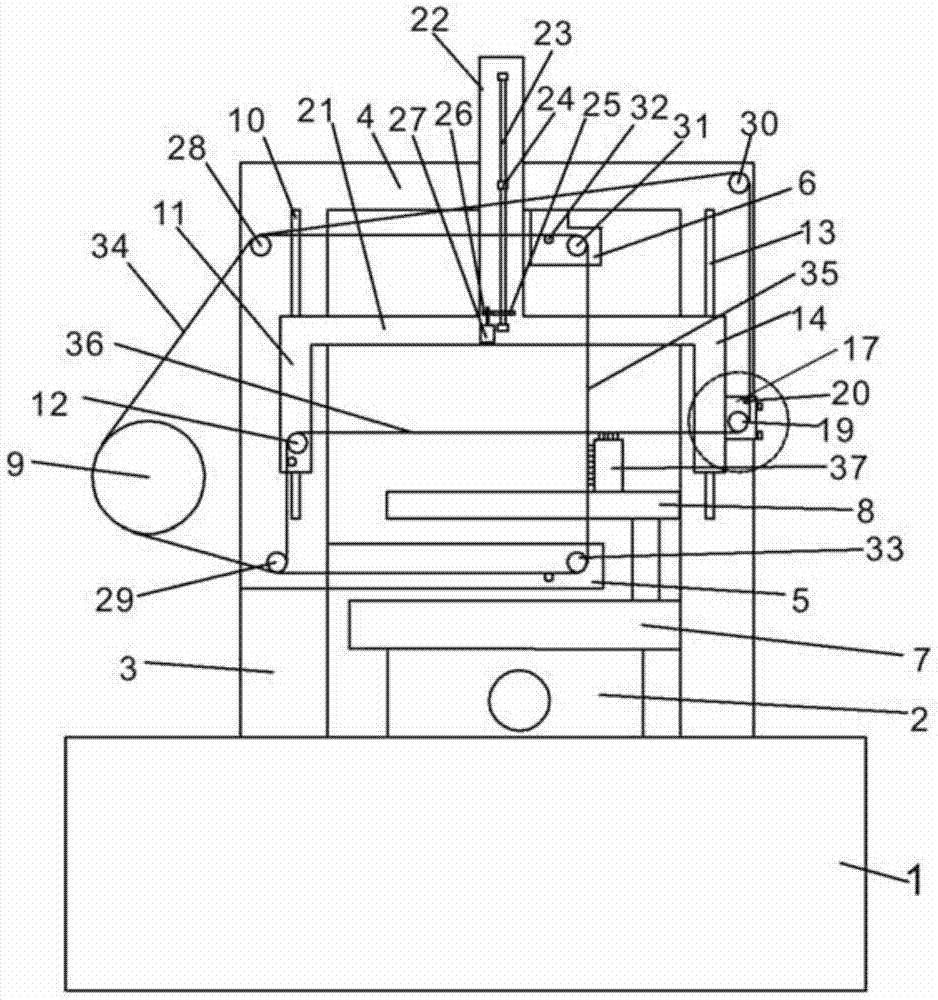

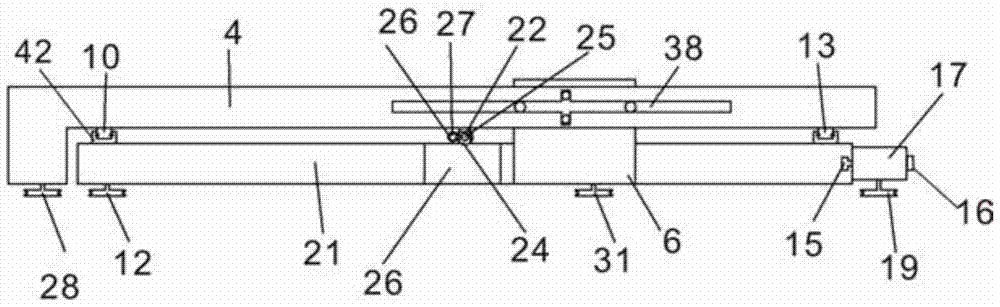

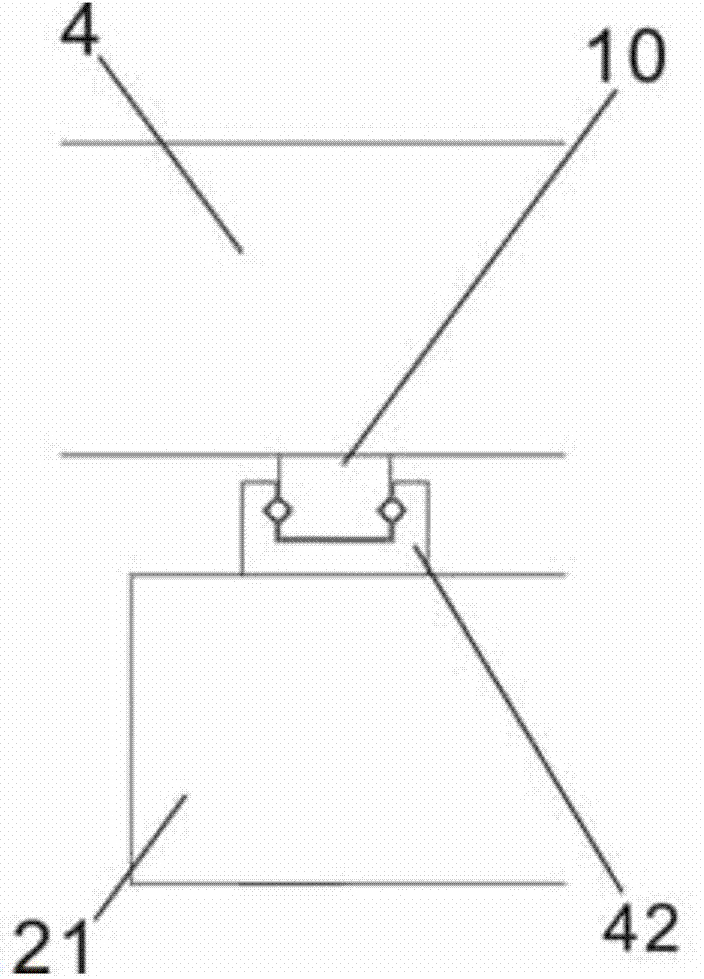

[0035] refer to Figure 1 to Figure 4 ,Such as figure 1 , figure 2 and image 3 A three-dimensional numerically controlled wire-cut electric discharge machine tool shown includes a bed 1, a cross slide 2 arranged on the bed 1, and left and right columns 3 fixed on the bed 1, and the left and right columns 3 The upper part is provided with a crossbeam 4 connecting the columns 3 on the left and right sides, the middle part of the left column 3 is provided with a lower wire arm 5, and the middle part of the crossbeam 4 is provided with an upper wire arm 6, a moving guide rail 38 and a screw pair 24. The upper wire arm 6 is slidably installed on the moving guide rail 38; the cross carriage 2 is provided with a working table 7, and the working table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com