Processing method for novel crease-resistant suit

A processing method and suit technology, applied in the field of clothing, can solve problems such as hidden dangers to health, human discomfort, and low durability of fabrics, and achieve the effects of high bonding strength between layers, good wearing comfort, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

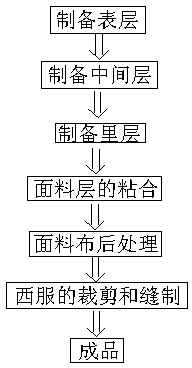

Image

Examples

Embodiment 1

[0016] The specific implementation process of the processing method of the novel anti-wrinkle suit mentioned in the present invention is as follows:

[0017] a) Prepare the surface layer. Rabbit hair is used as the raw material for the surface layer. Quantitative polyester fiber is blended in the wool material, and the polyester content is about 20%. The surface layer is prepared on a computerized flat knitting machine, and the woven fabric is fine knitted wool fabric with a width of 144cm. , the weight is about 240g / m*m, and the thickness is about 0.3mm; after the surface layer is prepared, it needs to be dyed, washed, singed and dried;

[0018] b) Prepare the middle layer, the middle layer is made of high-density polyester fiber cloth, the specification of the selected polyester fiber strip is 75D / 30F; 3:2, the weaving density of the fabric cloth is about 168*196, and the weaving thickness is about 0.15-0.2mm;

[0019] c) Prepare the inner layer, the inner layer is a blende...

Embodiment 2

[0024] The specific implementation process of the processing method of the novel anti-wrinkle suit mentioned in the present invention is as follows:

[0025] a) Prepare the surface layer. The raw material of the surface layer is sheep wool, which is blended with quantitative polyester fiber, and the polyester content is about 15%. The surface layer is prepared on a computerized flat knitting machine, and the woven fabric is a fine knitted wool fabric with a width of 144cm. , the weight is about 260g / m*m, and the thickness is about 0.35mm; after the surface layer is prepared, it needs to be dyed, washed, singeing, and dried;

[0026] b) Prepare the middle layer, the middle layer is made of high-density polyester fiber cloth, the specification of the selected polyester fiber strip is 75D / 30F; 3:2, the weaving density of the fabric cloth is about 168*196, and the weaving thickness is about 0.15-0.2mm;

[0027] c) Prepare the inner layer, the inner layer is a blended fabric of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com