Wire wrapping method and wire wrapping device of primary coils of current transformer

A technology of current transformer and winding device, applied in inductor/transformer/magnet manufacturing, coil manufacturing, circuit and other directions, can solve the problems of unfavorable coil forming, consumption of copper wire, low winding efficiency, etc., to save winding The required materials, the stability of the winding device, and the effect of simple demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] A winding method for a primary coil of a current transformer is changed from winding a square coil to a circular coil, so that the winding coil saves material and is easier to operate.

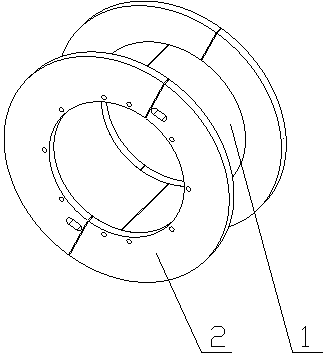

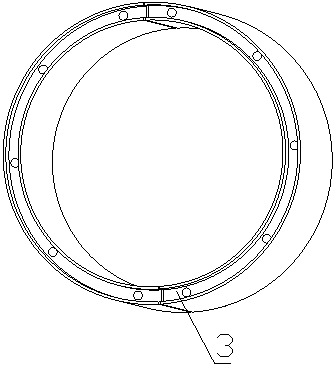

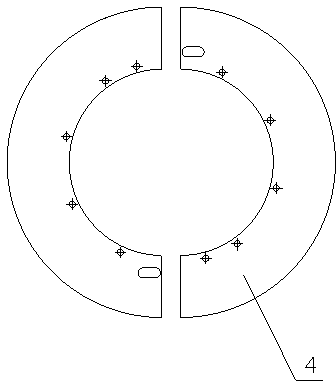

[0016] A winding device for a primary coil of a current transformer, comprising a cylindrical portion 1 and a wing portion 2, the cylindrical portion 1 is hollow in the middle, and is assembled from two semi-cylindrical parts 3, the end surface of the cylindrical portion 1 is open There are screw holes, the wing 2 is composed of two rings 5, the ring 5 is assembled from two semi-circular wing parts 4, and a positioning hole 6 is opened at the joint of the two semi-circular wing parts 4, and the ring The radius of the inner circle of 5 is equal to the radius of the cylindrical portion 1, and the semicircular wing 4 has a screw hole, and the wing 2 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com