Combined low-voltage bushing of transformer

A combined transformer and low-voltage bushing technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of difficult operation and backward installation method, and achieve the effects of simplified assembly process, simple structure and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

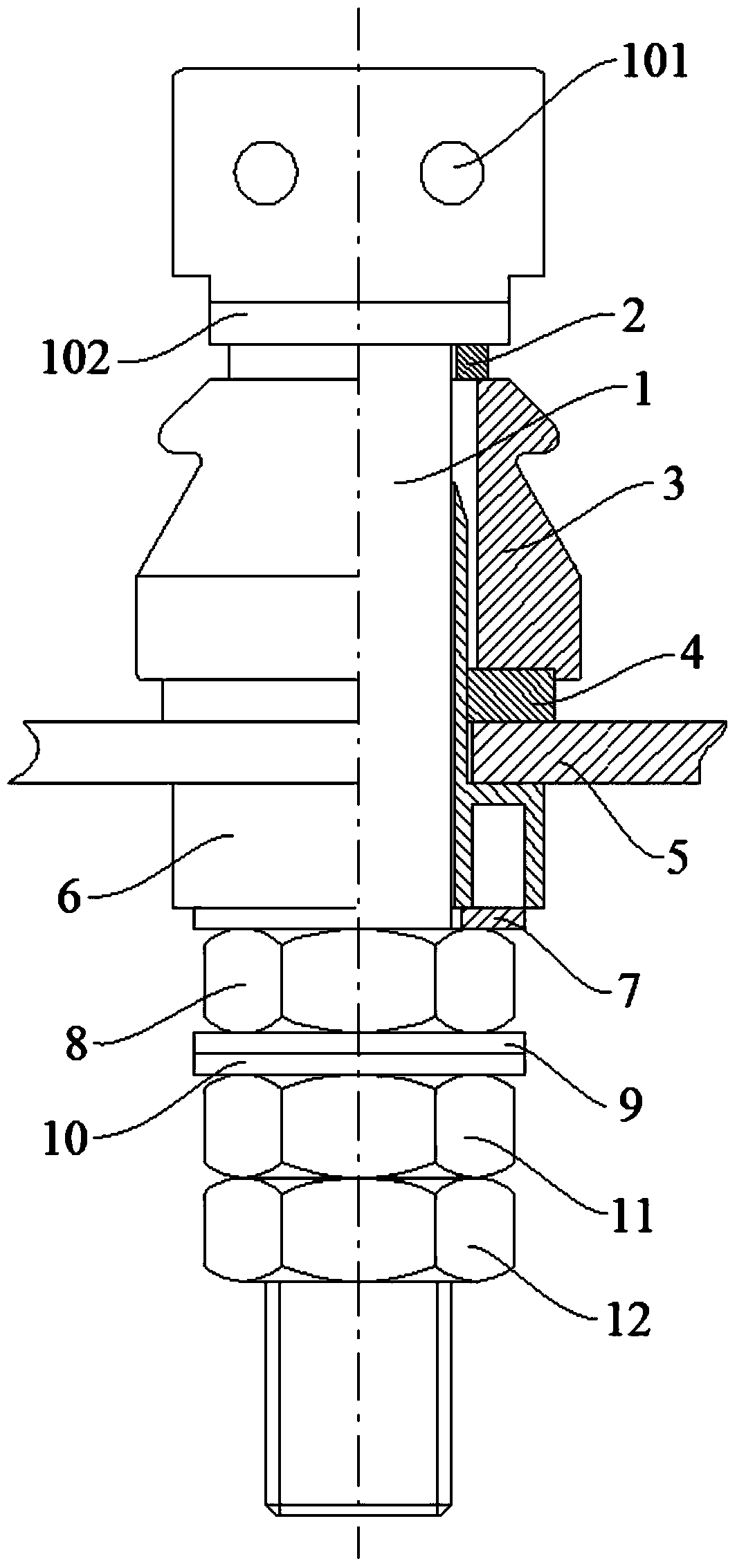

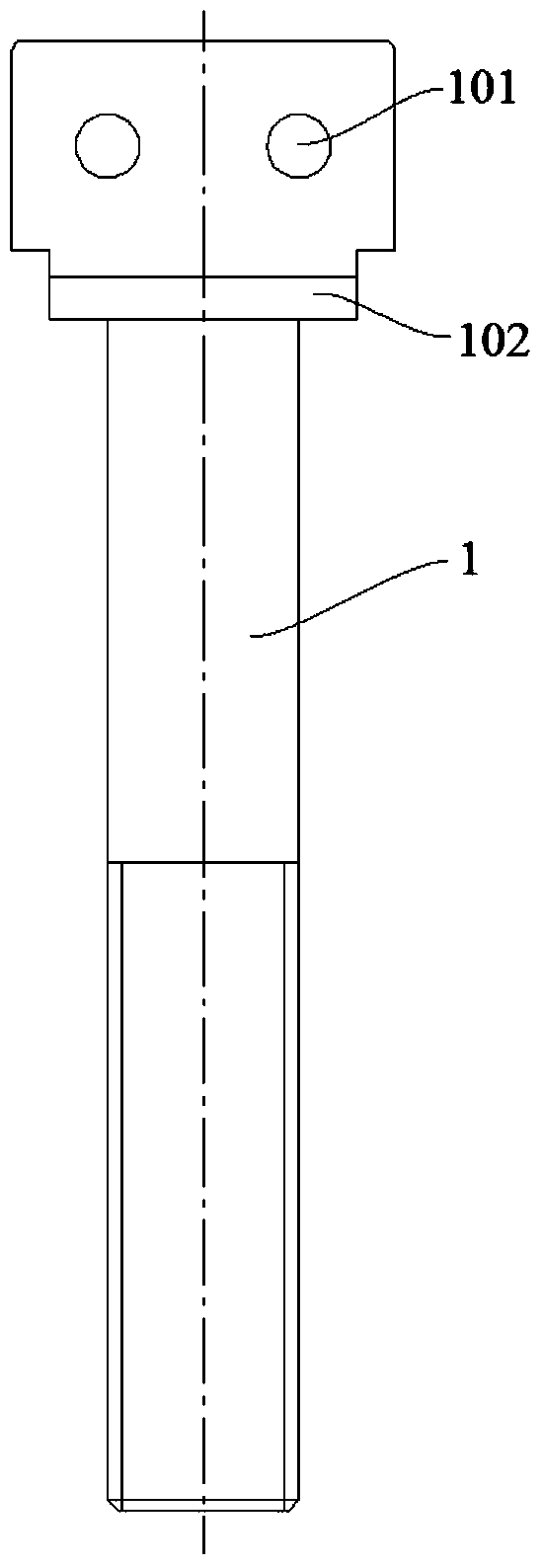

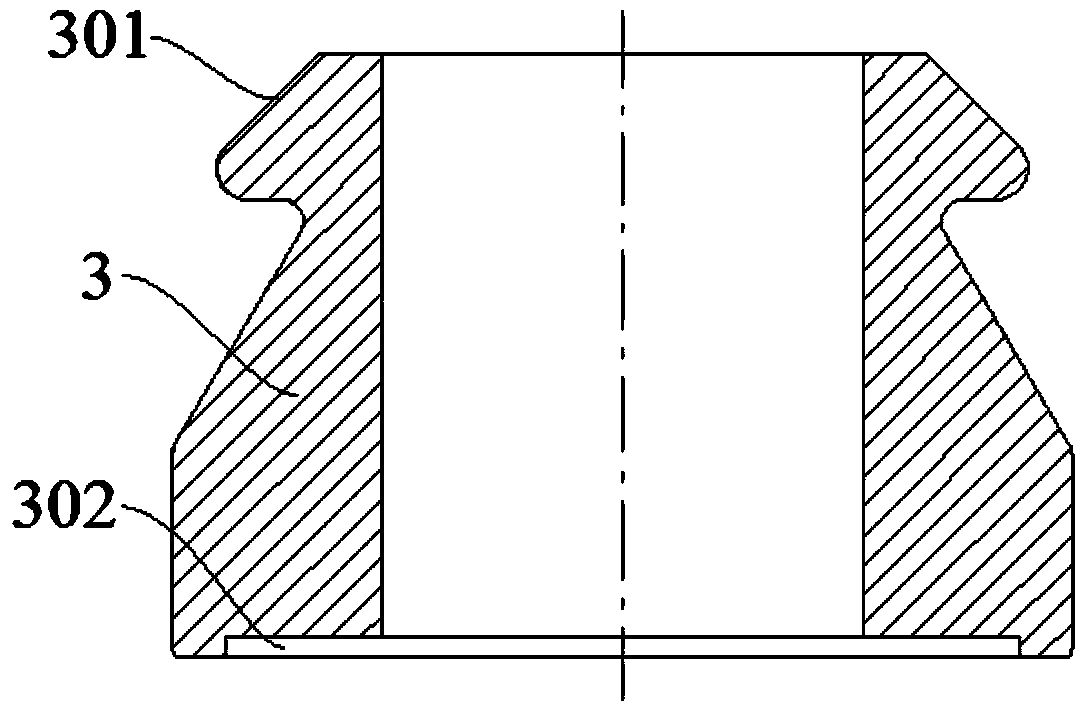

[0034] combine figure 1 with figure 2 , a combined transformer low-voltage bushing in this embodiment includes a conductive rod 1, a porcelain sleeve 3, a first sealing ring 2, a second sealing ring 4, a base 6 and a first nut 8, and one end of the conductive rod 1 is integrally formed with The round table 102 and the terminal, the terminal is located above the round table 102, without welding marks, avoiding local overheating due to poor welding, affecting the conduction of the conductive rod 1; the shape of the terminal is flat, and the terminal is provided with a wire The hole 101 can be easily connected with the wire, and the contact is good. The bottom of the round platform 102 is sequentially set with the first sealing ring 2, the porcelain sleeve 3, the second sealing ring 4 and the base 6. The radial dimension of the round platform 102 is larger than the radial dimension of the first sealing ring 2, preventing the first sealing ring 2 from Long-term direct exposure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com