Cementing type bell-shaped disk-shaped suspension type composite polymer string insulator unit

A technology of composite insulators and polymers, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of reduced creepage distance utilization, complex operating conditions, and affecting the safe operation of polymer insulators. Water-based, improved pollution flashover voltage, fast and convenient maintenance and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

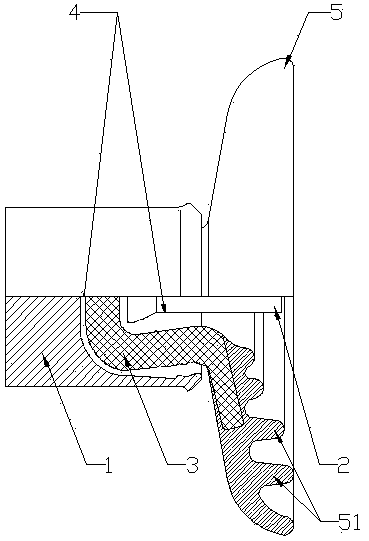

[0019] In order to better understand the purpose, structure and function of the present invention, a glue-mounted bell jar-shaped disc-shaped suspension polymer composite insulator string element according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the rubber-mounted bell jar-shaped disc-shaped suspension polymer composite insulator string element of the present invention includes: steel cap fittings 1, steel foot fittings 2, insulating core 3, and polymer shed 5; The inside of the steel cap fitting 1 is provided with a cavity with a U-shaped cross-section, and the steel foot fitting 2 is provided with a cone head part that is compatible with the cavity; the cone head part of the steel foot fitting 2 It is arranged in the cavity of the steel cap fitting 1, and an insulating core 3 is provided between the cone head and the cavity; the center of the insulating core 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com