A multifunctional colored insulating porcelain bottle

An insulating porcelain bottle and multi-functional technology, applied in the field of line tower insulators, can solve problems such as poor practicability and complex structure, and achieve the effects of reducing maintenance frequency, reducing three-phase unbalance, and ensuring insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

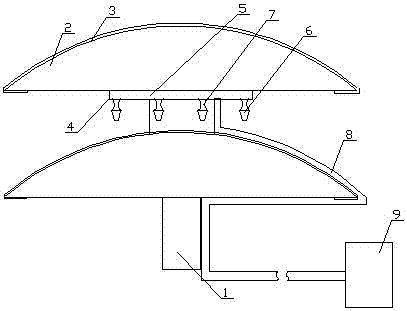

[0031] This embodiment provides a multifunctional colored insulating porcelain bottle, including an insulator 1, the upper surface and edge of the shed 2 of the insulator 1 are sprayed with identification paint 3, and a purging mechanism 4 is arranged under the shed 2, and the identification paint 3 is yellow in color.

[0032] The identification paint is made of the following materials by weight: 110 parts of WT800 silicone resin, 6.5 parts of butyl ester, 9 parts of xylene, 1 part of wetting agent, 2 parts of dispersing agent, 25 parts of pigment, 17 parts of filler, 3 parts of glass fiber, 1.2 parts of leveling agent, 4 parts of luminous powder.

[0033] The filler includes talcum powder and organic bentonite, and the weight ratio of the talc powder and the organic bentonite in the filler is 5:1.

[0034] The pigment is chrome yellow.

[0035] The leveling agent includes polydimethylsiloxane.

[0036] The particle size of the luminous powder is 1000 mesh, the luminous po...

Embodiment 2

[0038] This embodiment also provides a multi-functional colored insulating porcelain bottle, including an insulator 1, the upper surface and edge of the shed 2 of the insulator 1 are sprayed with identification paint 3, and a purging mechanism 4 is arranged under the shed 2, and the identification The color of paint 3 is green.

[0039] The identification paint is made of the following materials by weight: 100-120 parts of WT800 silicone resin, 5-8 parts of butyl ester, 7-11 parts of xylene, 0.5-1.5 parts of wetting agent, and 1-3 parts of dispersing agent. 20-30 parts of pigment, 14-20 parts of filler, 2-4 parts of glass fiber, 0.8-1.6 parts of leveling agent, 3-5 parts of luminous powder.

[0040] The filler includes talcum powder and organic bentonite, and the weight ratio of the talc powder and the organic bentonite in the filler is 5:1.

[0041] The pigment is cobalt green.

[0042] The leveling agent includes polydimethylsiloxane.

[0043] The particle size of the lum...

Embodiment 3

[0045] This embodiment also provides a multi-functional colored insulating porcelain bottle, including an insulator 1, the upper surface and edge of the shed 2 of the insulator 1 are sprayed with identification paint 3, and a purging mechanism 4 is arranged under the shed 2, and the identification The color of paint 3 is red.

[0046] The identification paint is made of the following materials by weight: 100-120 parts of WT800 silicone resin, 5-8 parts of butyl ester, 7-11 parts of xylene, 0.5-1.5 parts of wetting agent, and 1-3 parts of dispersing agent. 20-30 parts of pigment, 14-20 parts of filler, 2-4 parts of glass fiber, 0.8-1.6 parts of leveling agent, 3-5 parts of luminous powder.

[0047] The filler includes talcum powder and organic bentonite, and the weight ratio of the talc powder and the organic bentonite in the filler is 5:1.

[0048] The pigment is iron red.

[0049] The leveling agent includes polydimethylsiloxane.

[0050] The particle size of the luminous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com