Ash discharging device for alpha waste incineration ash

An ash discharge device and ash incineration technology, applied in nuclear engineering, radioactive purification, etc., can solve the problems of high dose of exposure to personnel, easy contamination of glove boxes, inconvenient operation, etc., and achieve reliable overall operation and accurate weighing and measurement , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings and implementation process.

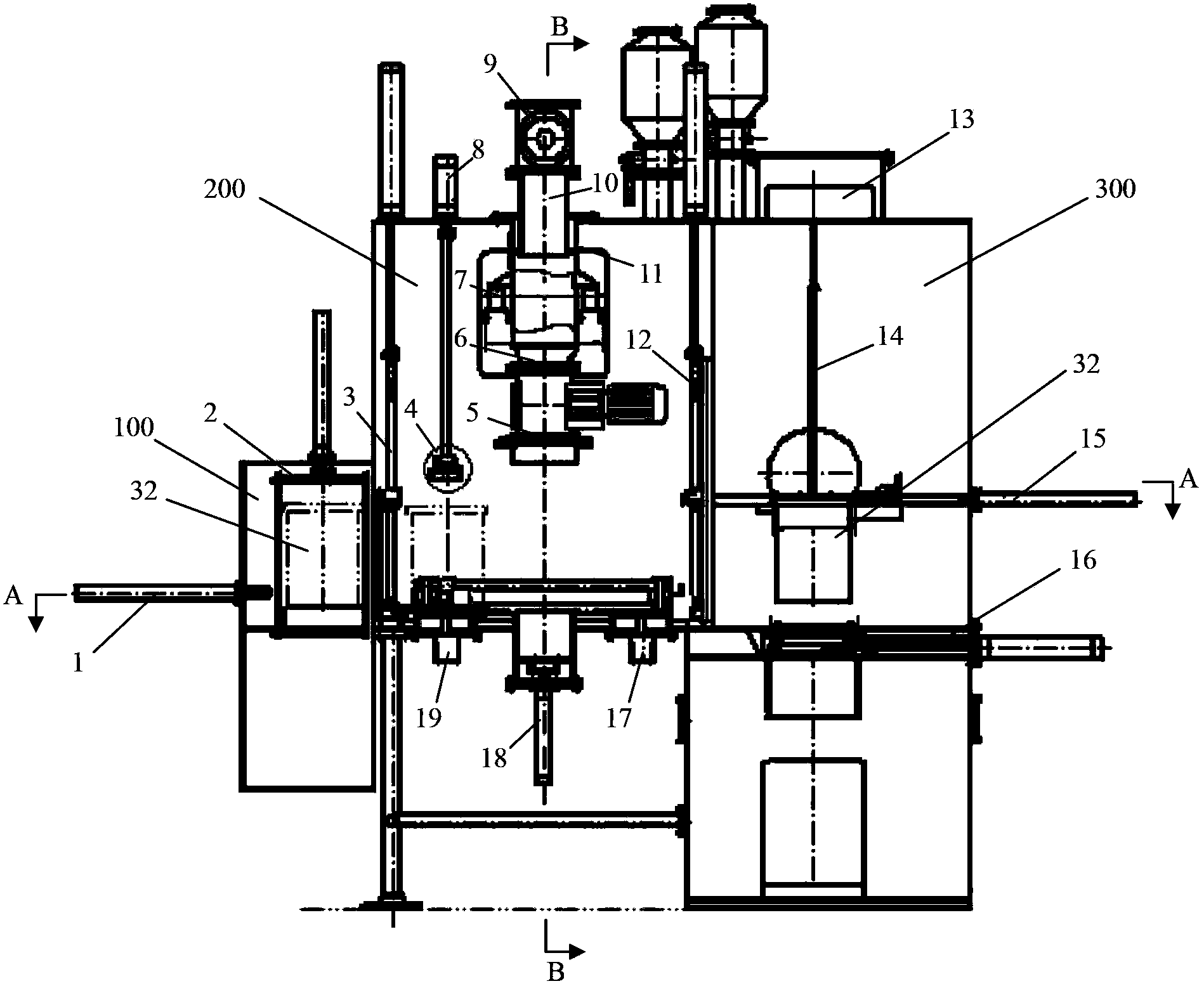

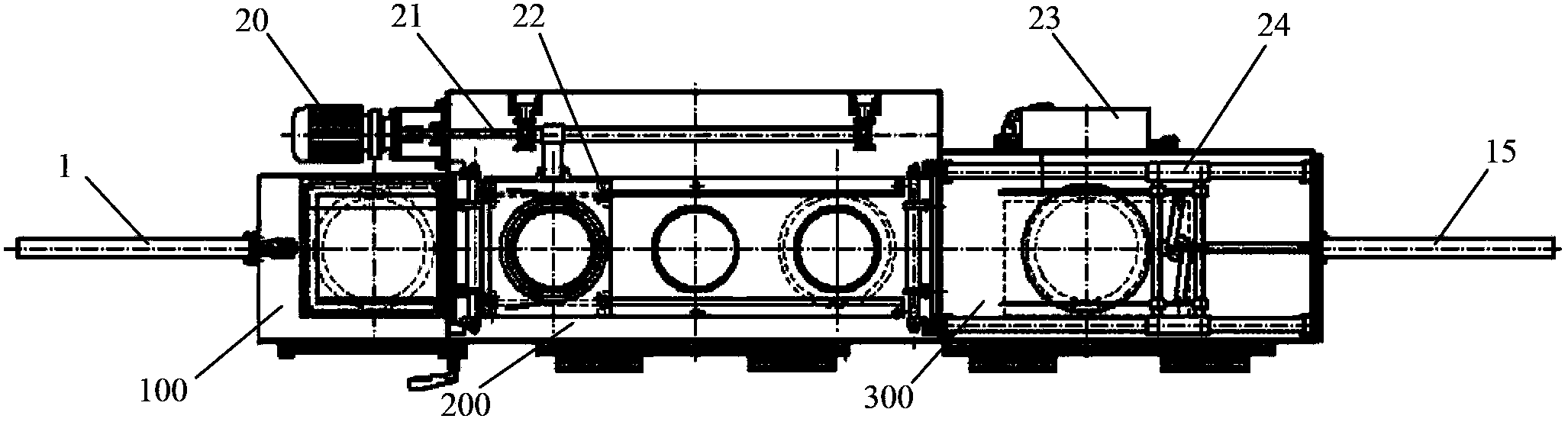

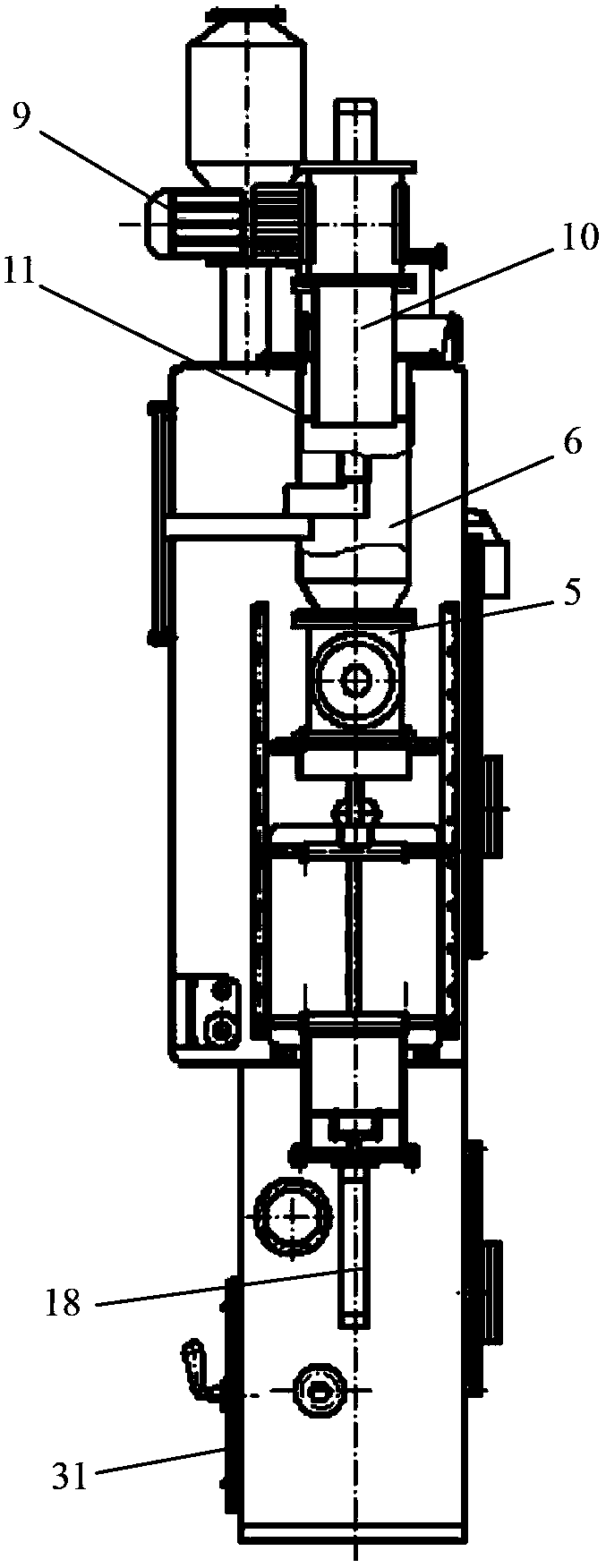

[0022] Such as Figure 1-4 As shown, the α waste incineration ash discharge device provided by the present invention includes an ash bucket 32, an ash discharge working box and a control system. The ash discharge work box is a main auxiliary box glove box structure equipment, including a barrel-inlet auxiliary box 100, an ash-discharging main box 200, and a barrel-out auxiliary box 300. The main material of the equipment is 304 stainless steel. The barrel-feeding sub-box 100 is an upper and lower double-layer sealed chamber structure, and is sealed and isolated from the ash discharge main box 200 through the sealing gate I3. The barrel-feeding sub-box 100 is equipped with a bucket lifting mechanism 2 and a bucket pushing cylinder 1; The ash main box 200 is provided with a buffer storage tank 6 connected to the ash discharge conduit 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com