Ratchet type tensioner

A tensioner and ratchet-type technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems that the meshing teeth 536 are easy to be missing, misassembled, and meshing mismatches, etc., and achieve the effect of easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

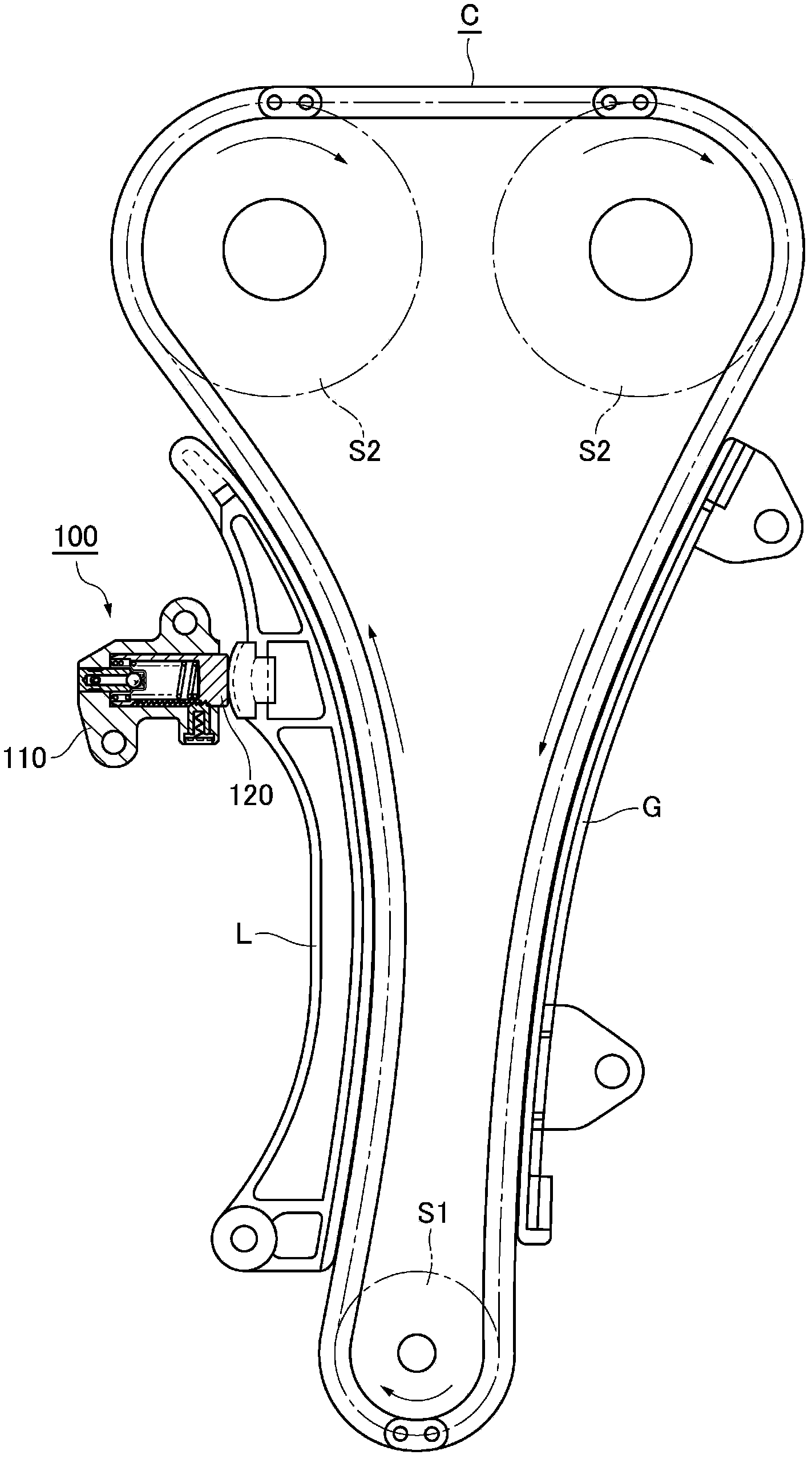

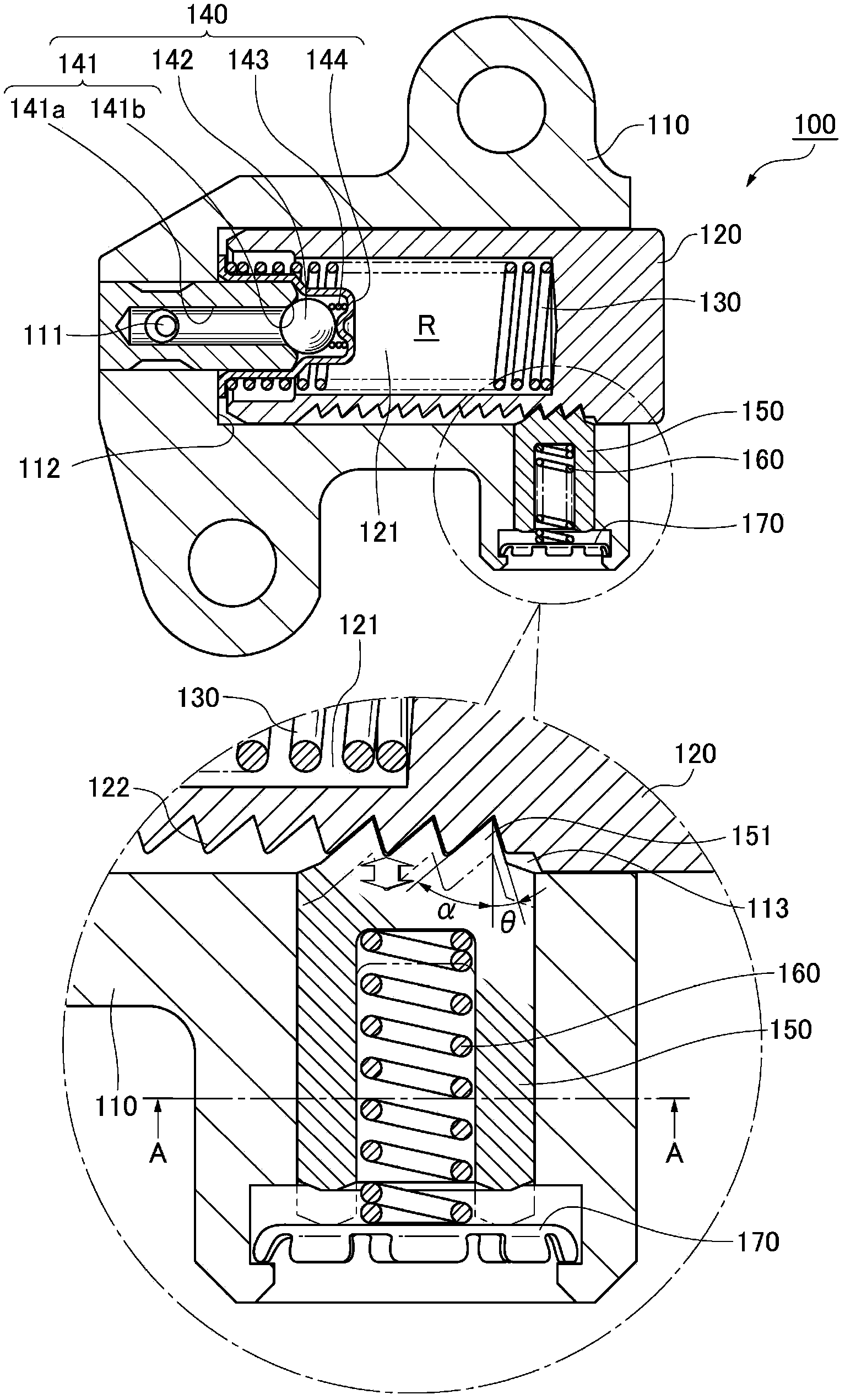

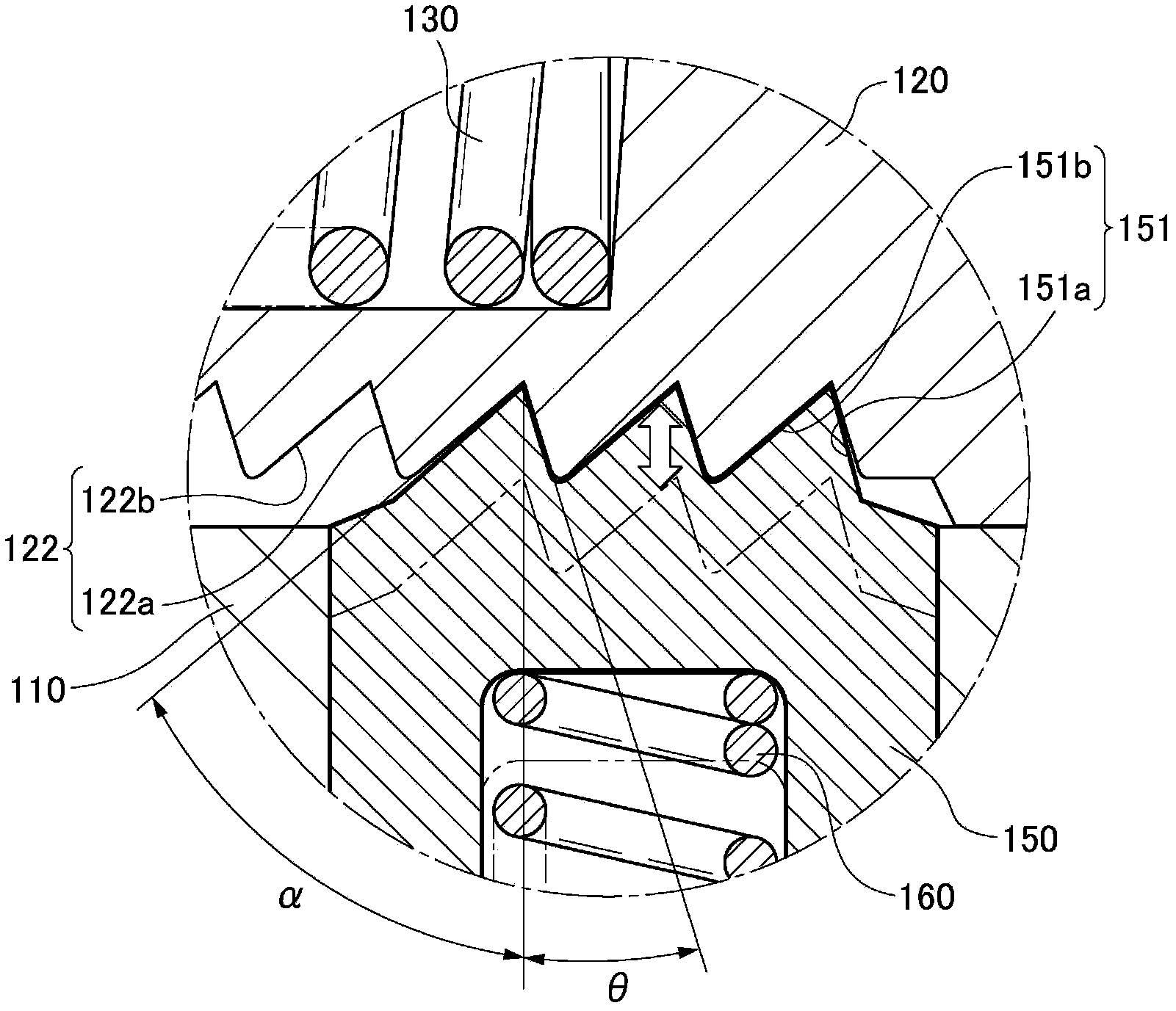

[0120] The ratchet type tensioner of the present invention includes: a housing body on which an oil supply passage for external pressure oil is formed; a plunger protruding freely from a plunger receiving hole of the housing body toward a traveling chain; In the high-pressure oil chamber formed between the plunger receiving hole of the housing main body and the hollow part of the plunger, force is applied along the protruding direction of the plunger; the cylindrical ratchet is inserted into the ratchet receiving hole of the housing main body, and Sliding in a direction perpendicular to the direction of advance and retreat of the plunger; the spring for ratchet loading loads the ratchet teeth provided at the front end area of the plunger side of the ratchet toward the rack teeth on the side of the plunger; the spring lock plug , embedded near the rear end of the ratchet receiving hole and used for the ratchet to be loaded by a spring. The ratchet release mechanism uses a too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com