Automobile engine

An automobile engine and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as engine failure, crankcase ventilation system failure, and engine performance, so as to reduce the risk of icing and avoid disadvantages impact, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

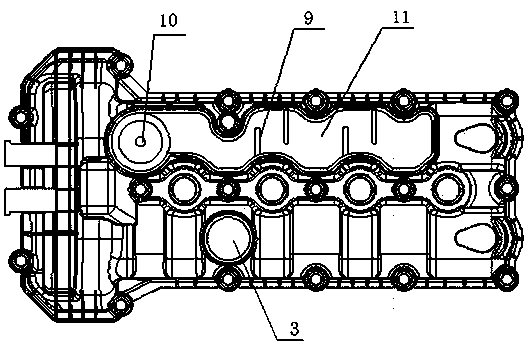

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 , figure 2 The automobile engine shown comprises a cylinder head 8, a cylinder head cover 1, a thermostat seat 7 and an engine water inlet pipe 4, the cylinder head cover 1 is installed on the cylinder head 8, and the thermostat seat 7 is installed on one end of the cylinder head 8, The cylinder head cover 1 is a plastic part, which is provided with an oil filling port 3, a wave-shaped oil sump 11, a labyrinth cover plate 12 for sealing the oil sump, and a shape that is located on one side of the oil sump 11 and bends toward one end of the oil sump 11. The L-shaped water jacket 2, the oil filling port 3 is located at the outer end of the L-shaped bend of the water jacket 2, and is integrated with the water jacket 2, and several fins 9 are alternately arranged on the two side walls in the length direction of the oil collection tank. One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com