Auxiliary bracket moving device of circular self-moving advance support

A technology of advanced support and self-moving, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of difficult to guarantee the walking track, slow moving speed, low operating efficiency, etc., and achieve reasonable structural design, Use safe and reliable, mobile stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

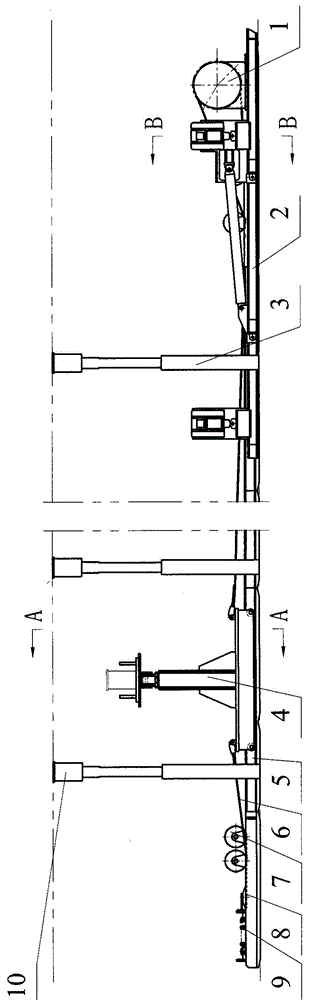

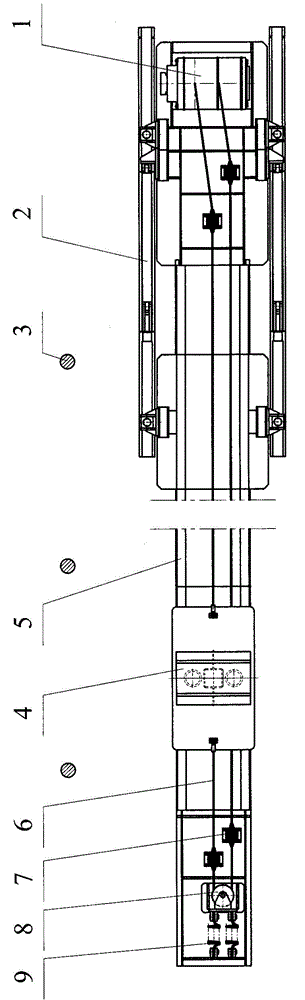

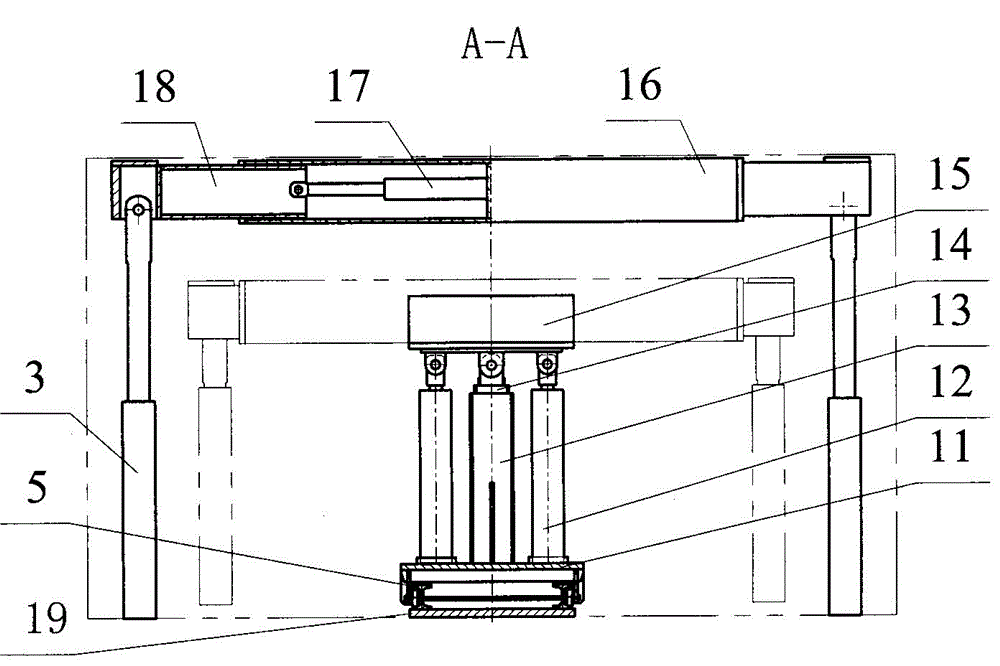

[0021] according to Figure 1-6The specific structure of the present invention will be described in detail. The cyclic self-moving type advanced support auxiliary moving device includes an advanced support bracket arranged longitudinally and continuously along the wind tunnel, which is composed of a telescopic support top beam 10 and a hydraulic column 3 whose top is respectively hinged to the two ends of the telescopic support top beam 10. The conveying device and the like between the two hydraulic columns 3, wherein the conveying device includes a combined base plate composed of a wide base plate 24 and a narrow base plate 19 connected in sections, a hydraulic winch and a tapped track 5 assembled on the combined base plate, assembled on The transport frame car 4 on the split track 5, and parts such as the self-moving device 2. The transport frame car 4 is composed of a sliding base 11 with moving rollers along the tapped track 5 at the bottom, a cylinder body and a guide sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com