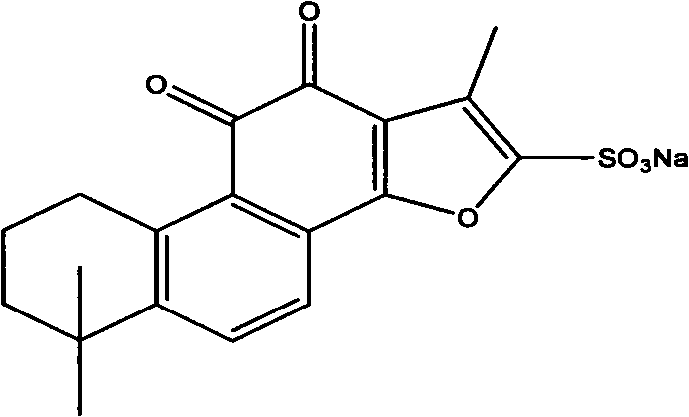

Tanshinone II A sulfonate, preparation method, and applications thereof

A technology of sodium sulfonate and tanshinone, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, steroidal compounds, etc., can solve problems such as difficult large-scale production, low product safety, and difficult operation, and achieve easy operation , Reduce production cost, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In a 5L constant temperature bath, add 50g of the crude product of tanshinone IIA sodium sulfonate (produced by Shanghai First Biochemical Pharmaceutical Co., Ltd.), dissolve it with 3L of 80% (v / v) methanol solution at a temperature of 60°C, and stir until all dissolve. Add 25g of activated carbon (Shanghai Activated Carbon Factory Co., Ltd.), stir for 1 hour, and suction filter while it is hot. The filtrate is concentrated to 60% under reduced pressure (relative pressure -0.09MPa) at 35°C, and the concentrated solution is placed in a freezer at -3°C for refrigerated analysis. crystallized, frozen for 20 hours, suction filtered to dryness, and the filter cake was put into a vacuum oven at 30° C. to dry for 24 hours to obtain 47 g of pure tanshinone IIA sodium sulfonate, with a yield of 94%. After HPLC detection, the calculated content of the dry product was 98.9%; organic solvent residues detected by gas chromatography, methanol was 0.1%, and methylene chloride was not...

Embodiment 2

[0047] In a 5L constant temperature bath, add 50g of the crude product of tanshinone IIA sodium sulfonate (produced by Shanghai First Biochemical Pharmaceutical Co., Ltd.), dissolve it with 3L of 80% (v / v) methanol solution at a temperature of 60°C, and stir until all dissolve. Add 25g of diatomaceous earth, stir for 1.5 hours, and suction filter while it is hot. The filtrate is concentrated to 60% under reduced pressure (relative pressure-0.1MPa) at 30°C. Suction filtration to dryness, the filter cake was put into a vacuum drying oven at 30°C and dried for 24 hours to obtain 46 g of pure tanshinone IIA sodium sulfonate, with a yield of 92%. The calculated content of the dried product was 99.4% through HPLC detection; The solvent remained, methanol was 0.05%, and dichloromethane was not detected.

Embodiment 3

[0049] In a 5L constant temperature bath, add 50g of crude sodium tanshinone IIA sulfonate (produced by Shanghai First Biochemical Pharmaceutical Co., Ltd.), dissolve with 3.5L of 90% (v / v) methanol solution, the temperature is 55% ℃, stir until completely dissolved. Add 15g of activated carbon (Shanghai Activated Carbon Factory Co., Ltd.), stir for 1 hour, and suction filter while it is hot. The filtrate is concentrated to 45% under reduced pressure (relative pressure -0.09MPa) at 30°C, and the concentrate is placed in a freezer at 7°C for freezing and crystallization. , frozen for 20 hours, suction filtered until dry, and the filter cake was dried in a vacuum oven at 30°C for 20 hours to obtain 46 g of pure tanshinone IIA sodium sulfonate, with a yield of 92%. The calculated content of the dry product was 99.3% by HPLC detection. %; gas chromatography detection of organic solvent residues, methanol was 0.08%, dichloromethane was not detected.

[0050] The above-mentioned fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com