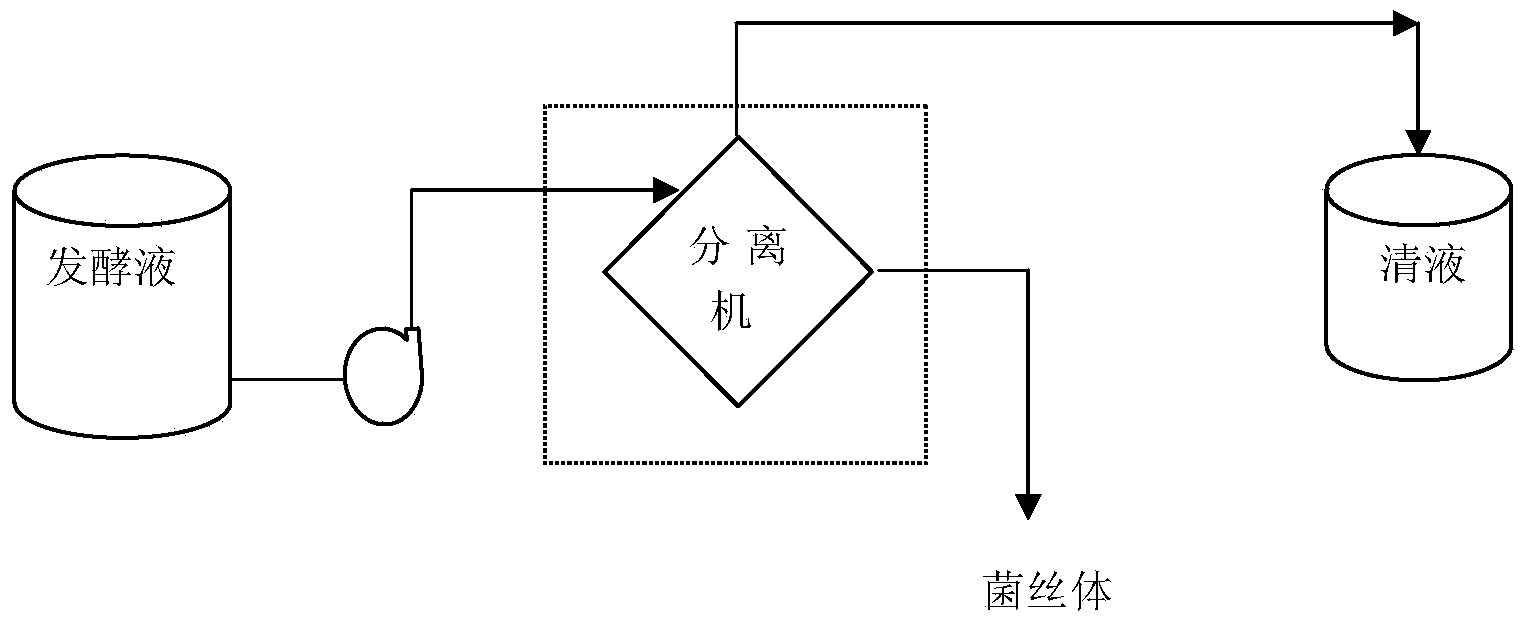

Extraction process of lysine fermentation liquor

The technology of lysine fermentation liquid and extraction process is applied in the field of lysine fermentation liquid extraction process of new feed additives, which can solve the problems of high production cost and maintenance cost, achieve low maintenance cost, less downtime and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Taking the disc separator countercurrent washing process as an example, the feed amount is 18g / dl, the total solid content is 22-24% (w / w), the insoluble solid content is 1-2% (w / w), and the feed amount at 20m 3 / h, the amount of washing water added is 6m 3 / h, small slagging time interval: 2s, large slagging time interval: 55min, solids content in top flow of separator ≤0.4%, mycelium content in bottom flow ≤1g / dl, total yield ≥98.5%.

Embodiment 2

[0022] Taking the disc separator countercurrent washing process as an example, the feed amount is 18g / dl, the total solid content is 22-24% (w / w), the insoluble solid content is 1-2% (w / w), and the feed amount at 17m 3 / h, the amount of washing water added is 8m 3 / h, small slagging time interval: 2s, large slagging time interval: 55min, solids content in top flow of separator ≤0.2%, mycelium content in bottom flow ≤1g / dl, total yield ≥99%.

Embodiment 3

[0024] Taking the disc separator countercurrent washing process as an example, the feed amount is 15g / dl, the total solid content is 22-22% (w / w), the insoluble solid content is 1-2% (w / w), the feed amount at 17m 3 / h, the amount of washing water added is 8m 3 / h, small slagging time interval: 2s, large slagging time interval: 55min, solids content in top flow of separator ≤0.2%, mycelium content in bottom flow ≤1g / dl, total yield ≥99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com