Device for exciting micro-jet with laser and detonator using the device

A jet and laser technology, applied in the direction of detonators, fuze ignition devices, fuze connection casings, etc., can solve the problems of undiscovered micro-jet excitation detonator devices and detonators, and achieve strong anti-electromagnetic interference, accurate delay, and high ignition capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Laser excitation device for micro-jet

[0030] Dissolve 5 g of the bi-base drug in 50 ml of acetone, and cast the mixed solution on a PET film with a thickness of 80 microns. The wet film thickness is 100 microns. The dry film thickness after drying for 1 hour at 30 degrees Celsius is 10 Micron, a laser-excited micro-jet device is made.

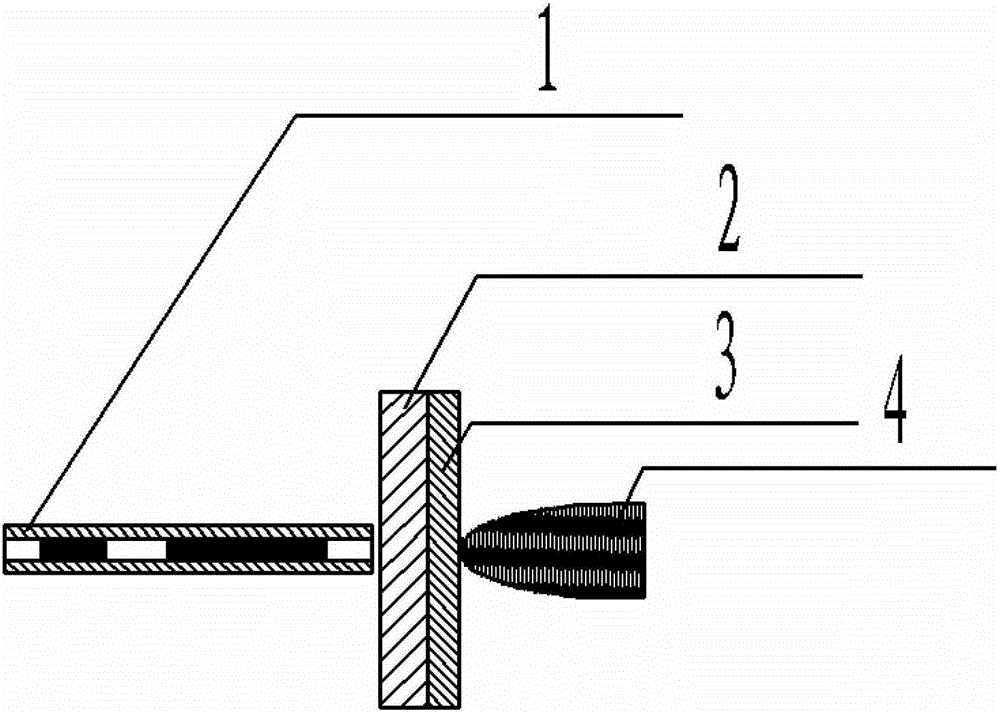

[0031] figure 1 A schematic diagram of the action process of the laser micro-jet device of the present invention is given. Such as figure 1 Shown in: Optical fiber 1 conducts the laser light emitted by the laser source, the wavelength of the laser light emitted by the laser source is 1064nm, and the power is 1W. The thickness of the PET substrate 2 is 80 microns, and the light transmittance is 90%. The thickness of the double-base drug film 3 is 10 microns. The micro jet 4 is produced under the action of the laser.

[0032] Using a vacuum torsion pendulum to test the laser energy utilization rate of the micro-jet under this con...

Embodiment 2

[0036] Example 2: Laser-excited micro-jet device 2

[0037] Dissolve 3 grams of bi-base drug and 2 grams of polyglycidyl azide in 50 ml of a mixture of ether and ethanol with a volume ratio of 7:3, and cast the mixed solution on a polyimide film with a thickness of 50 microns Above, the wet film thickness is 6000 micrometers, and the dry film thickness after drying for 10 hours at 90 degrees Celsius is 2000 micrometers, and a laser-excited microjet device is produced. The laser beam emitted by the laser source has a wavelength of 940nm and a power of 5W.

[0038] Using a vacuum torsion pendulum to test the laser energy utilization rate of the micro-jet under this condition can exceed 300%, that is, 1J of laser energy acting on the micro-jet generating device can generate a micro-jet with an energy of 3J, and the single pulse can be improved after using this equipment Laser energy.

[0039] The energetic polymer used in the laser-excited microjet device in this embodiment can also b...

Embodiment 3

[0041] Example 3: Using laser to excite the detonator of the micro-jet device

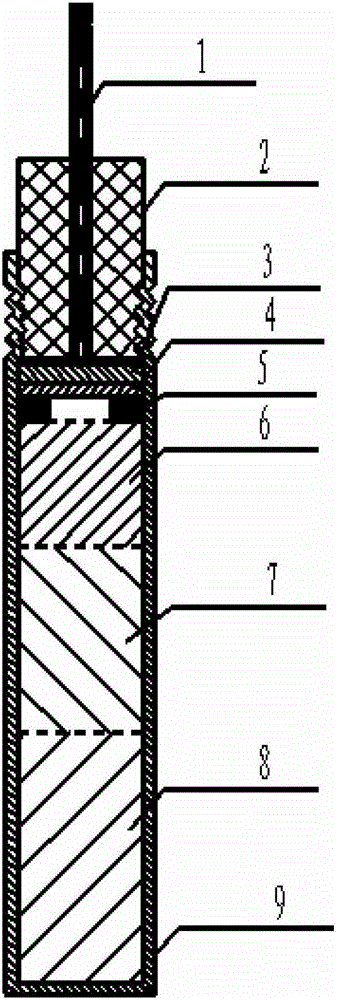

[0042] In this embodiment, a detonator made by the above-mentioned laser-excited polymer on the back of a transparent substrate to generate a micro-sputtering flow is used. image 3 A schematic diagram of the structure of the detonator using the laser microjet device of the present invention is given. Combine below image 3 To illustrate the manufacturing process of the detonator in this embodiment.

[0043] The iron shell of the detonator used in making the detonator of this embodiment has an outer diameter of 7 microns and an inner diameter of 6.2 mm; a charge of 8 black gold is added to the iron shell 9 with a charge of 0.4 g and a density of 1.4 g / cm 3 , And then add the secondary charge of 7 Roxy Gold, the charge is 0.3 g, the density of the press is 1g / cm 3 , And then add three charges of 6 RDX, the charge is 0.3 grams, and the charge density is 0.9g / cm 3 ; Press into the rubber ferrule 5 with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com