Material fluidization pressurization tube device

A pressurized tube, fluidized technology, used in the transportation of bulk materials, transportation and packaging, conveyors, etc., can solve problems such as increased transportation resistance, deterioration, and reduced material flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

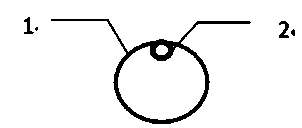

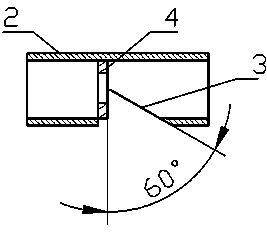

[0019] A material fluidization sending device is installed at the lower part of the sintering flue gas desulfurization device in the iron and steel plant, and then the material fluidization sending device is connected with the material fluidization pressure pipe device. A material fluidization pressure pipe device consists of two sets Tube composition, conveying material fluidization large pipe 1 and double casing inner pipe 2, the connection relationship is that the upper part of the conveying material fluidization large pipe 1 is equipped with double casing inner pipe 2.

[0020] The inside of the double casing inner tube 2 is equipped with throttling orifice plates 4 equidistantly and uniformly.

[0021] The said throttling orifice plate 4 is welded to the inner wall of the double sleeve inner tube 2 .

[0022] The material of the throttle orifice 4 is 16Mn.

[0023] The rear of the throttling orifice plate 4 of the tube wall of the double-sleeve inner tube 2 is equally sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com