Material fluidization sending method

A fluidization and material technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve problems such as deterioration, increase in conveying resistance, and affect material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

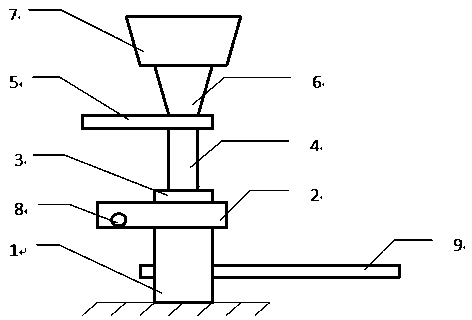

Embodiment approach 1

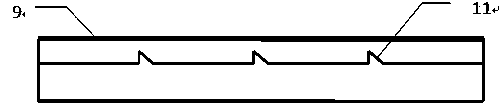

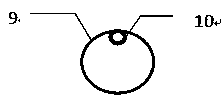

[0022] In the lower part of the sintering flue gas desulfurization device, a method of material fluidization delivery is implemented, and a material fluidization delivery device is installed, which consists of a waste slag bucket 7 at the bottom of the tower, a variable diameter joint 6, a knife gate valve 5, a pipeline 4, and a waveform Compensator 3, double gate feed valve 2, and sender 1. The connection relationship is: the bottom of the waste slag hopper 7 at the bottom of the tower is connected to the upper part of the variable diameter joint 6, and the lower part of the variable diameter joint 6 is connected to the inlet of the knife gate valve 5. , the outlet of the knife-shaped gate valve 5 is connected to the inlet of the pipeline 4, the outlet of the pipeline 4 is connected to the upper part of the wave compensator 3, the lower part of the wave compensator 3 is connected to the inlet of the double ram feed valve 2, and the double ram feed The outlet of the valve 2 is ...

Embodiment approach 2

[0035] In the step (2), when the main ash conveying pipeline has a bend in the conveying process, adjust the internal pressure of the main ash conveying pipeline to ≥0.3Mpa.

[0036] The remaining steps are the same as above and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com