Disk stone sawing machine refitted through excavator

A circular saw and excavator technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of unsuitable cutting operations, limited use occasions, only vertical cutting, etc., to improve the yield and operation. Efficiency, reduced equipment setup, and the effect of convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

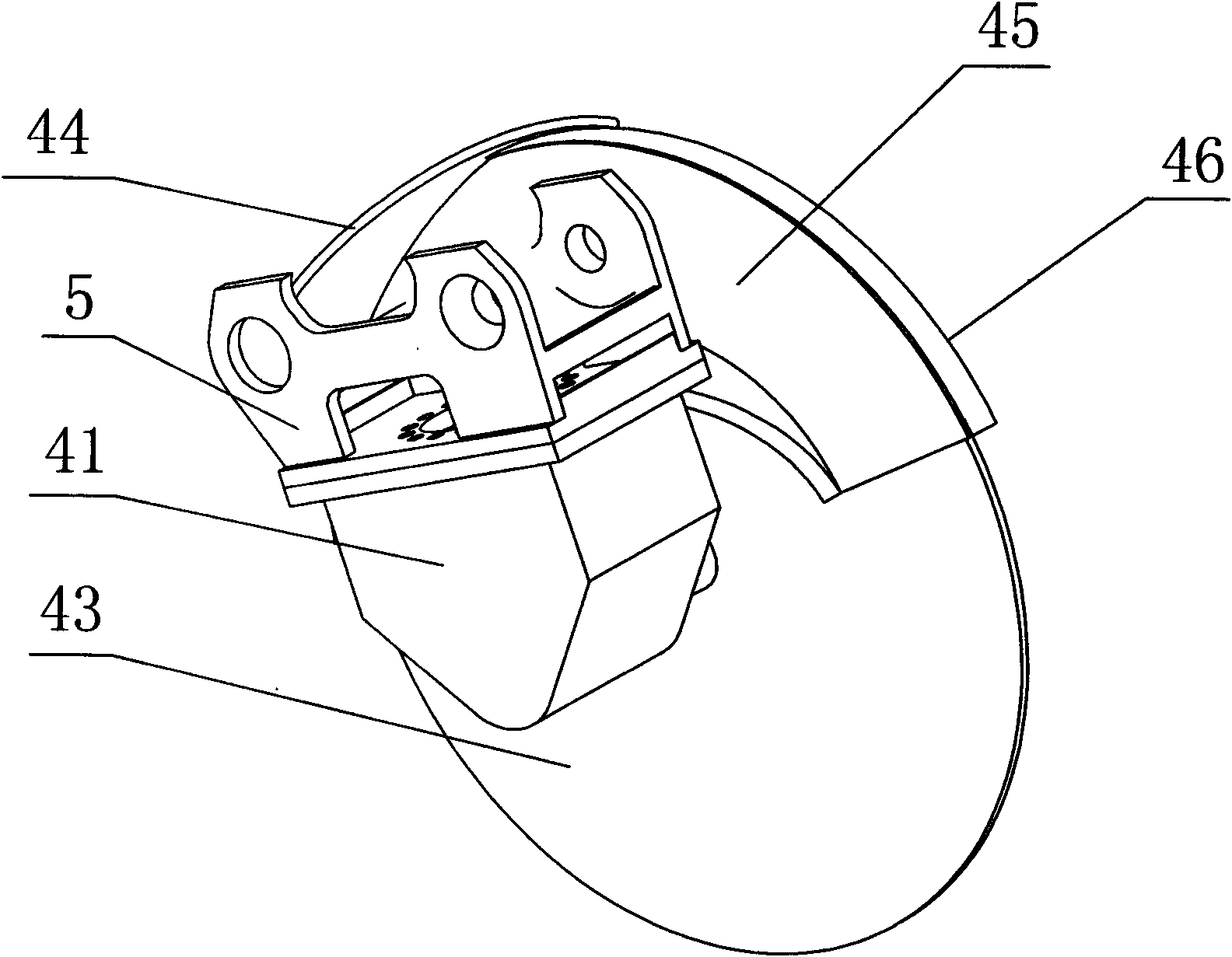

[0027] refer to figure 2 , Figure 4 Shown, a kind of circular saw 4 structure that excavator is refitted into, it comprises excavator body 1, mechanical arm and circular saw 4; Described mechanical arm comprises big arm 2 and forearm 3, and the One end is hinged with the vehicle body 1 , and the other end is hinged with one end of the small arm 3 ; the circular saw 4 is connected to the other end of the small arm 3 through a connecting plate 5 . The circular saw 4 includes a saw blade 43, a motor assembly 41 for driving the saw blade 43 to rotate, and a rotating assembly 42 for driving the saw blade 43 and the motor assembly 41 to rotate. The sheet 43 is connected to the motor assembly 41 which is connected to the rotating assembly 42 .

[0028] Described motor assembly 41 can be various structures, for example: can be following two structures:

[0029] The first structure includes a first housing and a first motor and a transmission shaft arranged in the first housing; t...

Embodiment 2

[0040] refer to image 3 , Figure 5 Shown, a kind of circular saw 4 structure that excavator is refitted into, it comprises excavator body 1, mechanical arm and circular saw 4; Described mechanical arm comprises big arm 2 and forearm 3, and the One end is hinged with the vehicle body 1 , and the other end is hinged with one end of the small arm 3 ; the circular saw 4 is connected to the other end of the small arm 3 through a connecting plate 5 .

[0041] In this embodiment, the circular saw 4 includes a saw blade 43 and a motor assembly 41 driving the saw blade 43 to rotate, and the saw blade 43 is connected to the motor assembly 41 . That is, in this embodiment, the structure of the rotating assembly 42 is omitted.

[0042] Described motor assembly 41 can be various structures, for example: can be following two structures:

[0043] The first structure includes a first housing and a first motor and a transmission shaft arranged in the first housing; the output shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com