Flexible tooling for milling and turning machining centers

A composite machining center and flexible tooling technology, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve problems such as processing difficulties and reduce processing efficiency, and achieve the effects of improving processing efficiency, saving time, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

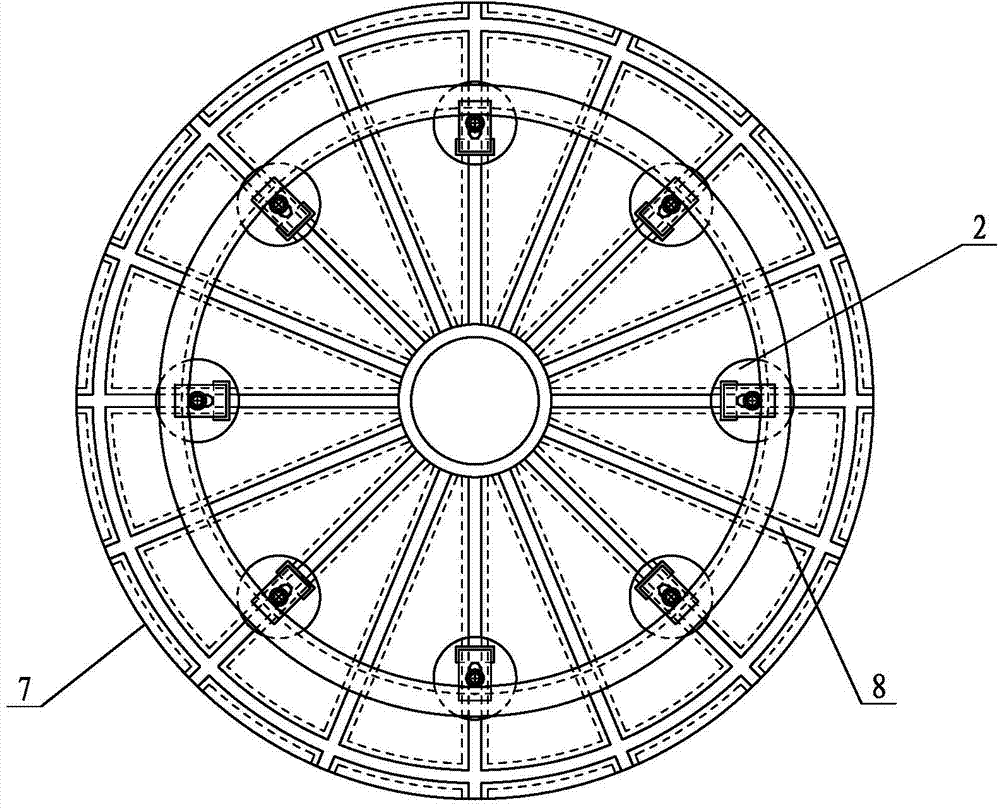

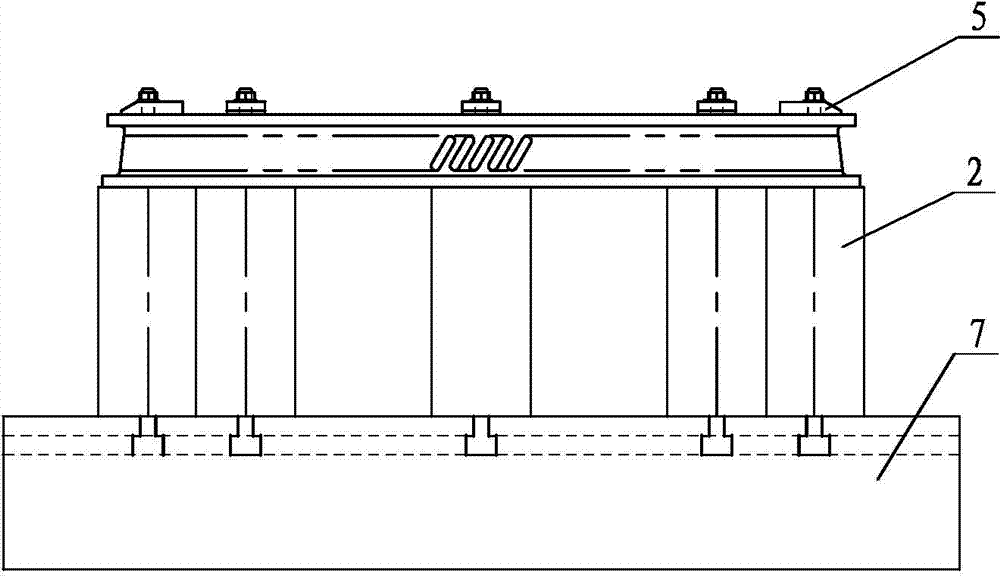

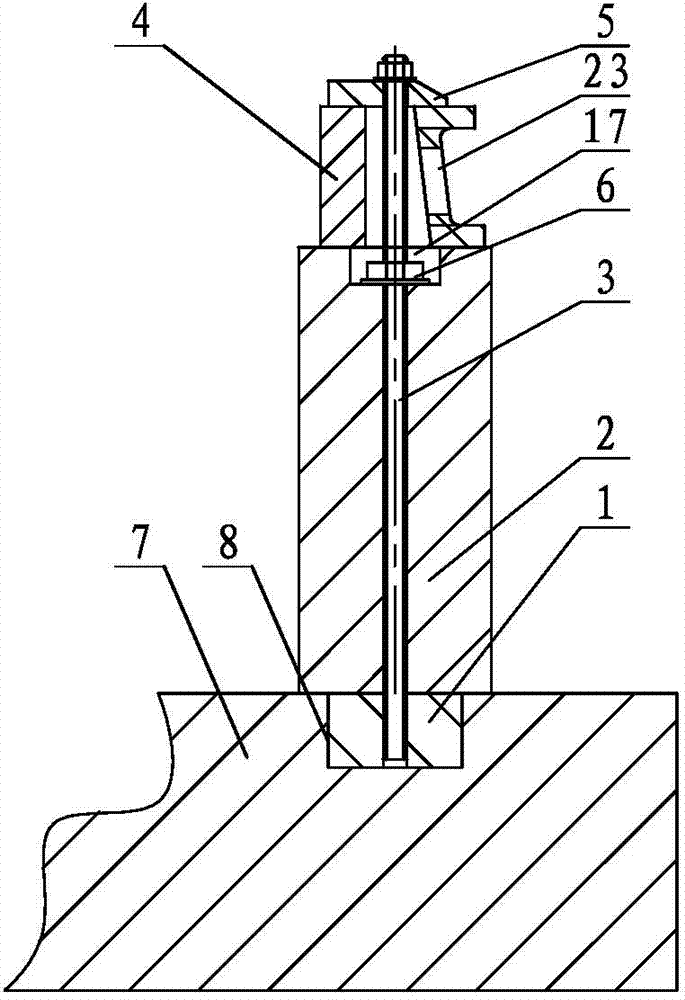

[0012] Specific implementation mode one: combine Figure 1 ~ Figure 3 and Image 6 with Figure 7 Explain, the flexible tooling of the milling-turning compound machining center in this embodiment, the flexible tooling of the milling-turning compound machining center includes at least two T-shaped blocks 1, at least two cylinders 2, at least two screws 3, and at least two pads 4. At least two pressure plates 5 and at least four nuts 6; the at least two T-shaped blocks 1, at least two cylinders 2, at least two screws 3, at least two pads 4 and at least two pressure plates 5 The numbers are all the same, the number of nuts 6 is twice the number of screw rods 3, and the at least two T-shaped blocks 1 are set upside down in the inverted T-shaped chute 8 of the machine tool workbench 7, and the T-shaped blocks set upside down 1 is matched with the inverted T-shaped chute 8 of the machine tool table 7, and a cylinder 2 is erected on the upper surface of each inverted T-shaped block...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 , Image 6 with Figure 7 Note that the number of cylinders 2 in this embodiment is two to eight. Select according to the size of the outer diameter of the workpiece 23 to be processed. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 4 with Figure 5 Explain that the flexible tooling of the milling and turning compound machining center in this embodiment includes a faceplate 9, at least two nuts one 10, at least two T-shaped blocks one 11, at least two T-shaped blocks two 12, and at least two pressure plates one 13 , at least two pressure plates 14, at least two pads 15, at least two pads 16, at least two cylinders 2, at least two screw rods 18, at least two screw rods 19 and at least four nuts two 20;

[0015]The quantity of described at least two pressing plates one 13, at least two pads one 15, at least two screw rods two 19, at least two cylinders 2 and at least two T-shaped blocks one 11 is all the same, and the at least two pressing plates Two 14, at least two pads two 16, at least two screw rods two 19 and at least two T-shaped blocks two 12 have the same quantity, the number of nut one 10 is twice the number of screw rod one 18, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com