Preparing method of iron powder for powder metallurgy

A technology for powder metallurgy and iron powder, applied in the field of preparation of iron powder for powder metallurgy, can solve the problems of high energy consumption, high labor intensity and many impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

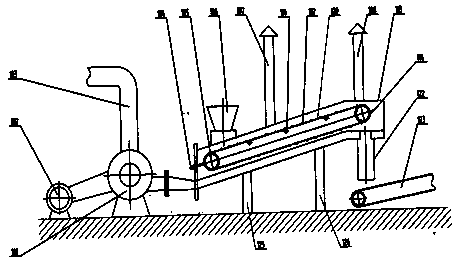

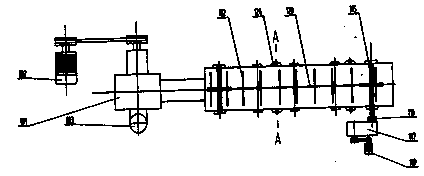

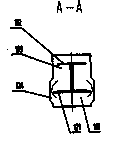

[0127] Embodiment 1 A. The equipment used in the preparation method of iron powder for powder metallurgy provided by the present invention includes: (1) a chain-type double-chamber drying device for raw iron powder; (2) raw material iron powder (3) direct reduction iron powder tunnel kiln; (4) primary reduction iron cleaning device; (5) primary reduction iron crusher, produced by Zhengzhou Hongxing Machinery Co., Ltd., model C1200-35; (6) primary reduction Iron powder wind magnetic separator; (7) Steel belt machine for preparing iron powder for powder metallurgy, manufactured by Ningbo Sailing Heating Equipment Co., Ltd., model GD-1OOO-7500; (8) Pulverizer for iron powder for powder metallurgy, Choose Zhengzhou Hongxing Machinery Co., Ltd., model WN-1200; (9) Powder sieving machine for iron powder for powder metallurgy, choose Henan Xinxiang Sanhe Vibration Equipment Co., Ltd., model SX2-1200;

[0128] Introduce the equipment that the present invention develops below:

[0129...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com