Automobile 4S shop tire cushion for auto exhibition

A 4S shop and tire technology, applied in the field of materials and supplies in the car showroom, can solve the problems of high cost, signs can only be filled with paint, warped corners, etc., and achieve the effects of short production period, convenient portability, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

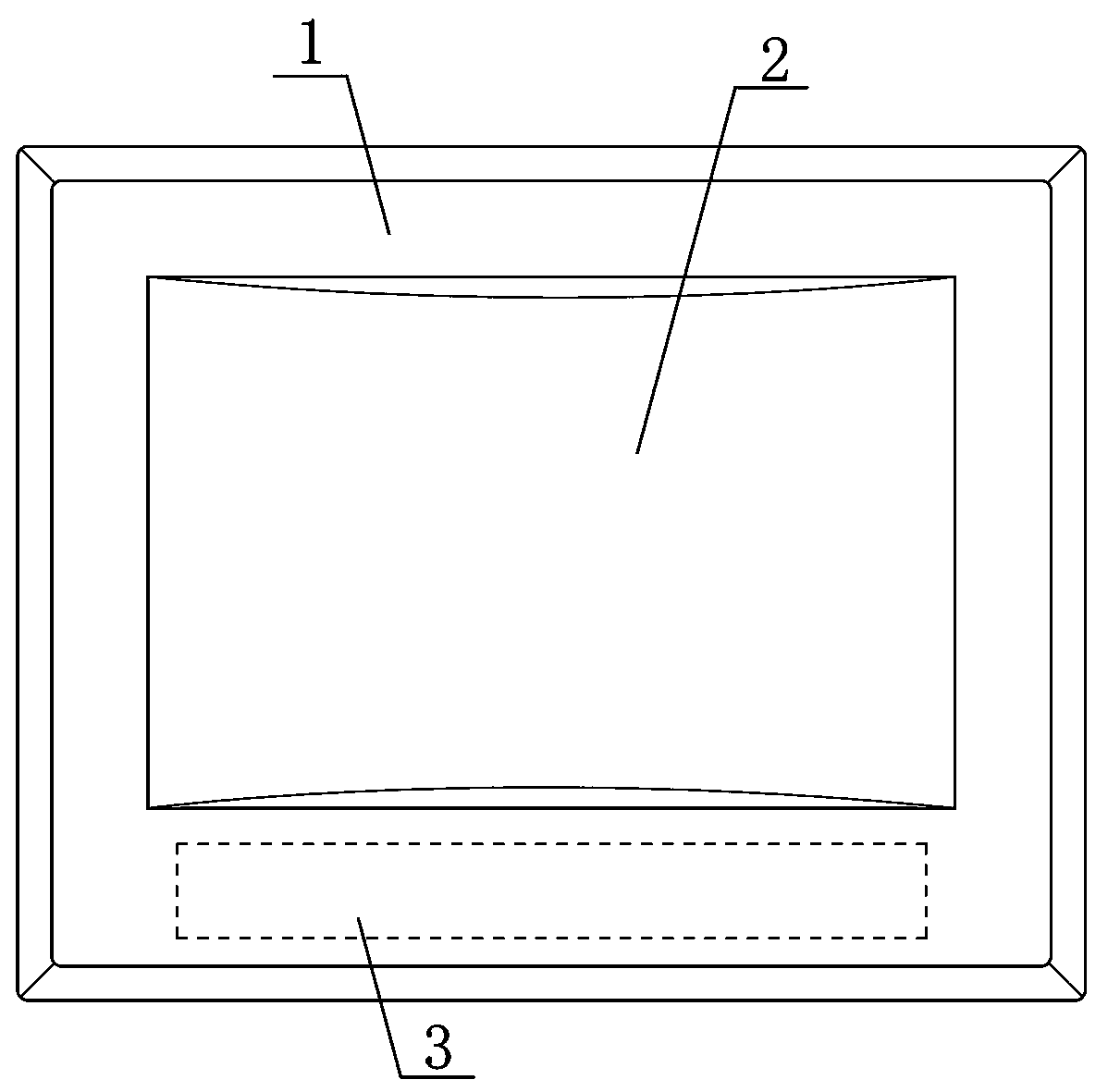

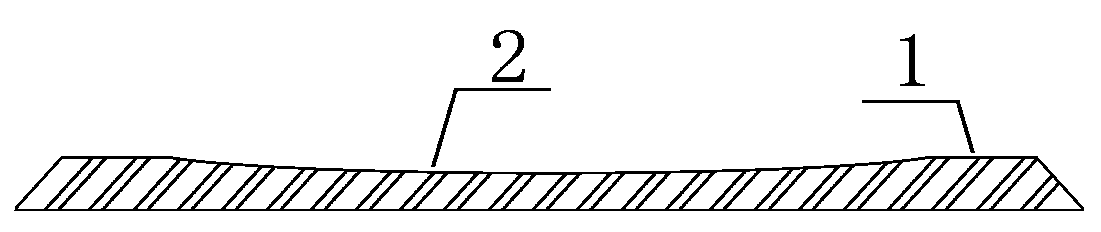

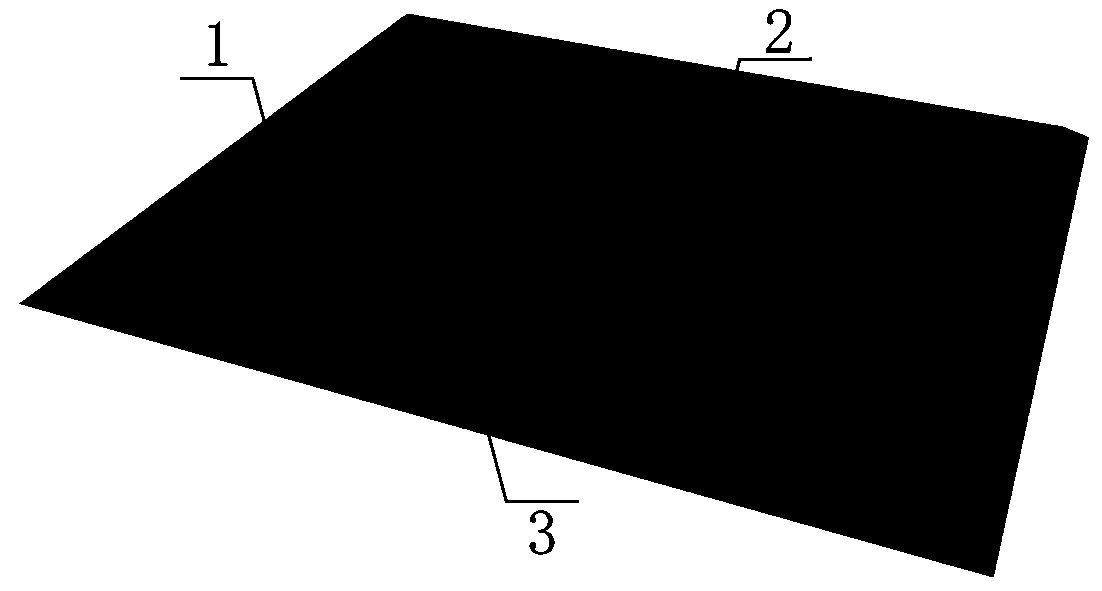

[0017] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 - -3. A car tire pad for 4S shops, including tire pad body (1), groove (2), and sign area (3). The groove (2) is made on the tire pad body (1). The mold is fixed on the mold, and the tire cushion body (1) is produced by using the mold.

[0018] The sign area (3) can be fixed on the mold together with the tire pad body (1) and the groove (2), or a mold for the sign area (3) can be made separately, and the prepared sign can be glued to the glued on the tire body (1).

[0019] The tire pad can be molded according to the material, size, and logo shape required by the customer. After the mold is completed, the tire pad can be produced by one-shot molding.

[0020] The above embodiment is only one embodiment of the present invention, and its description is more specific and detailed, but it should not be interpreted as limiting the scope of the patent of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com