Vending machine

A technology for vending machines and mobile mechanisms, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc., can solve the problem of increased manufacturing costs, reduced workability, and increased installation space. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

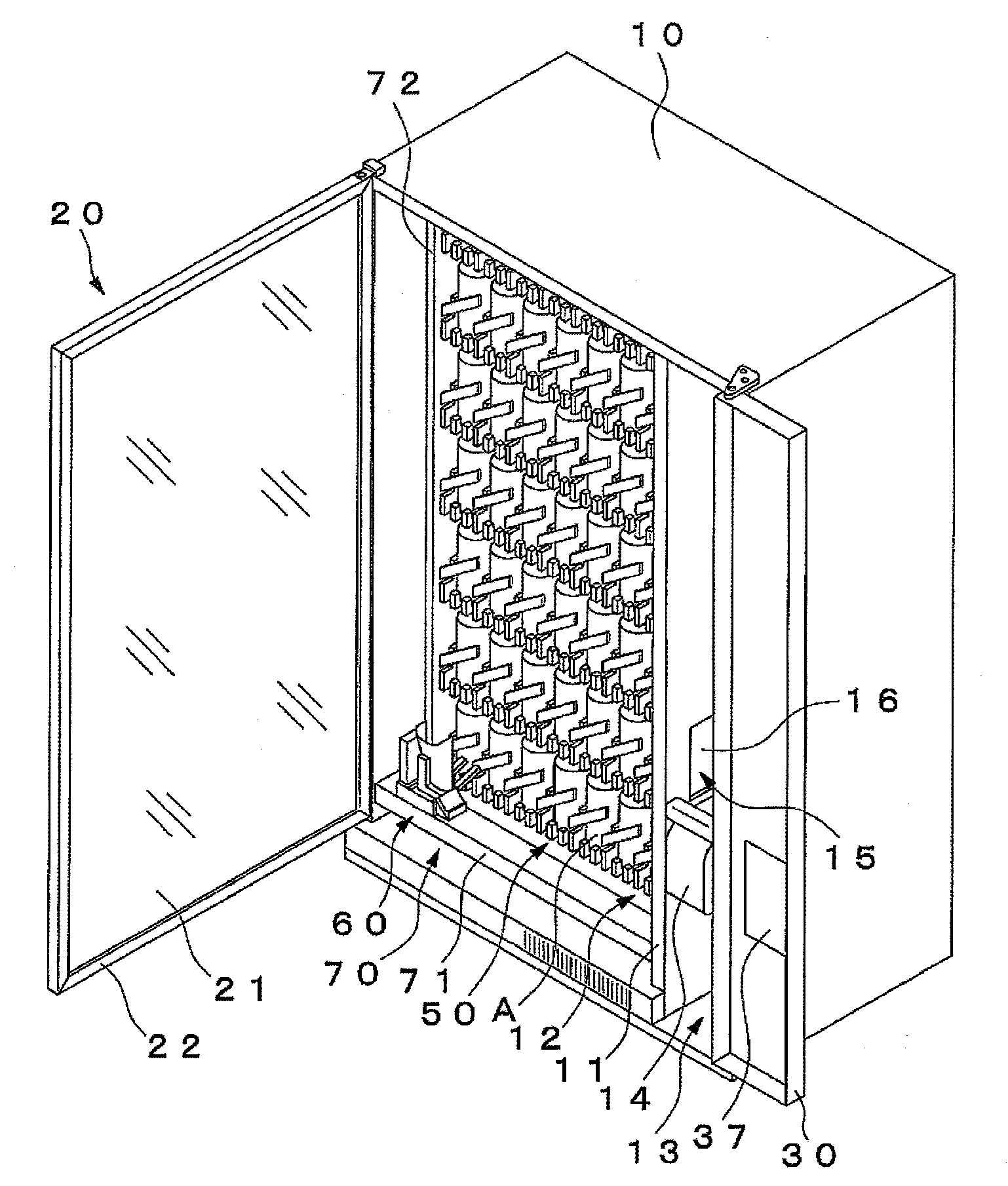

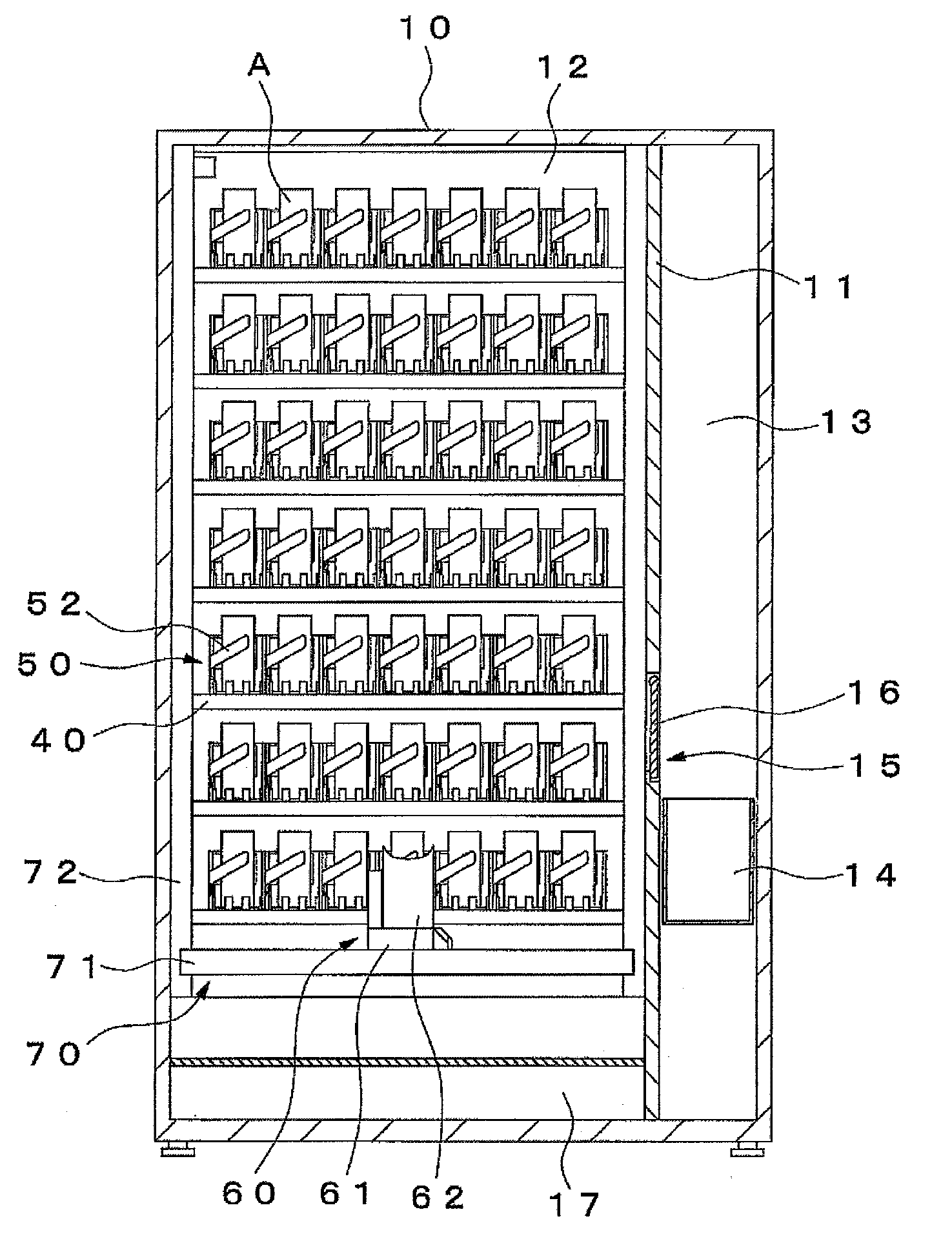

[0021] Figure 1 to Figure 6 An embodiment of the present invention is shown. This automatic vending machine is provided with: the automatic vending machine main body 10 of opening front surface, the outer door 20 of opening and closing the width direction one end side of the opening portion of the automatic vending machine main body 10 , and the width direction of the opening portion of the automatic vending machine main body 10 . The operation door 30 on the other end side.

[0022] The main body 10 of the automatic vending machine has a commodity storage 12 for accommodating commodities A for sale, and a machine storage 13 for accommodating machines for selling. spaced across the width. A product take-out unit 14 from which the product A is delivered is provided at a lower portion of the machine storage 13 , and an opening 15 connecting the product take-out unit 14 and the product storage 12 is provided on the partition wall 11 . Furthermore, the opening part 15 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com