Automatic locating and testing socket for CMOS camera shooting chip floating carrier plate

A test socket and automatic positioning technology, which is applied in the field of automatic positioning test socket of CMOS camera chip floating carrier board, can solve problems such as chip crushing, mechanical failure, and test efficiency reduction, and achieve convenient use, extended service life, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

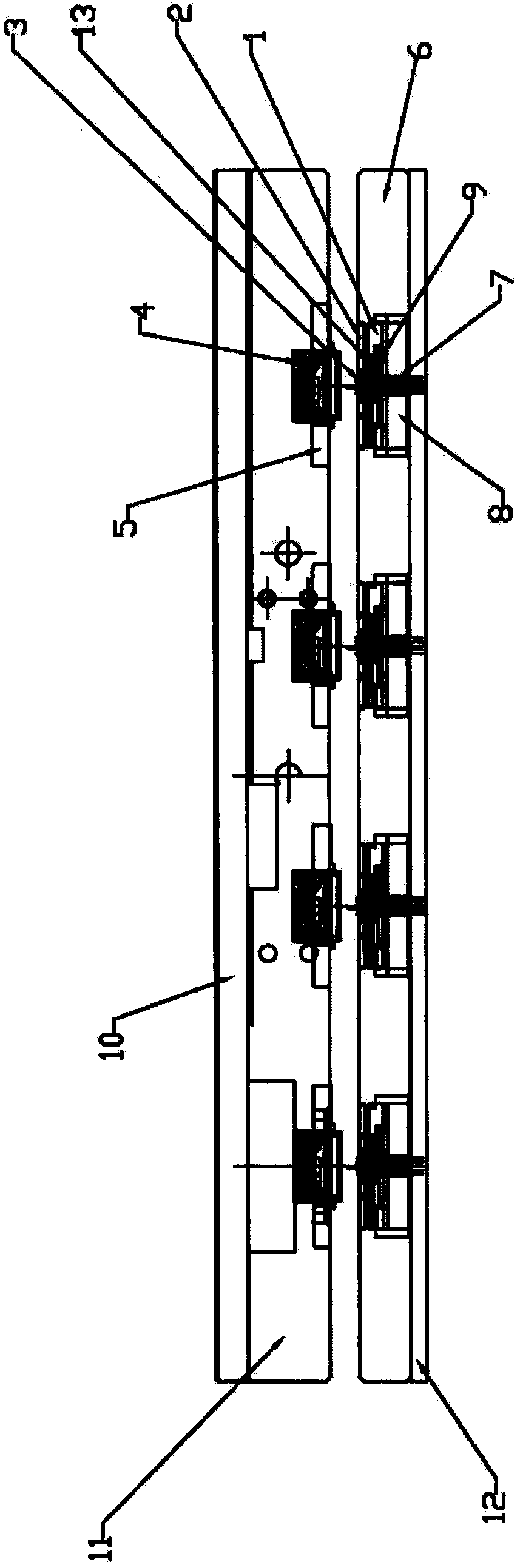

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

[0027] refer to figure 1 , a kind of CMOS imaging chip floating carrier plate automatic positioning test socket involved in the present embodiment comprises a cooperating upper cover and a base, and the base includes a PCB adapter board 12, a test unit and a floating carrier distributed sequentially from bottom to top. Board 1, the upper cover includes a test lens 4 and a lens pressure plate 5, a light source (such as an LED light board 10) is arranged in the dark room ahead of the test lens, and a contrast is also provided between the test lens and the light source. In the image, the test unit includes a plurality of test probes 7 and a probe holding body 9 for installing the test probes, a probe holding plate 8 and a probe holding frame 11 .

[0028] Further, when the upper cover and the base are closed, the float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com