Nano-zinc-oxide temperature sensor and manufacturing process thereof

A nano-zinc oxide and temperature sensor technology, applied in the field of nano-materials, can solve problems such as low precision, high cost, and wide measurement range, and achieve the effects of wide temperature measurement range, low cost, and easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

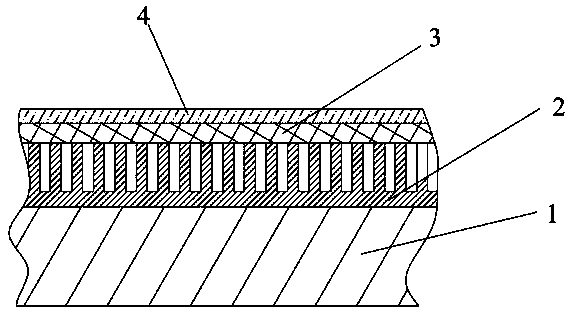

[0033] The preparation technology of nano-zinc oxide temperature sensor specifically comprises the following steps:

[0034] 1) Preparation of nano-zinc oxide: first, Na 2 CO 3 and Zn(NO 3 ) 2 solution, under constant stirring, Zn(NO 3 ) 2 The solution was dropped into Na 2 CO 3 The reaction is carried out in the solution, and then, the precipitate is separated and dried, and calcined at 400° C. for 36 minutes to obtain nano-zinc oxide, such as figure 2 shown;

[0035] 2) Preparation of porous anodized aluminum template: take a high-purity aluminum plate with a thickness of 5 mm, first clean it ultrasonically in a mixed solution of acetone and ethanol with a volume ratio of 1:1, and then clean it in a solution of ethanol with a volume ratio of 4:1. Polished in a mixed solution of perchloric acid (Ra ≤ 0.01μm) for 5 minutes; then, washed with deionized water and placed in a 0.3mol / L oxalic acid solution, anodized at a DC voltage of 40V for 0.5h, on a high-purity aluminu...

Embodiment 2

[0039] The preparation technology of nano-zinc oxide temperature sensor specifically comprises the following steps:

[0040] 1) Preparation of nano-zinc oxide: first, Na 2 CO 3 and Zn(NO 3 ) 2 solution, under constant stirring, Zn(NO 3 ) 2 The solution was dropped into Na 2 CO 3 The reaction is carried out in the solution, and then, the precipitate is separated and dried, and calcined at 450° C. for 60 minutes to obtain nano-zinc oxide, such as figure 2 shown;

[0041] 2) Preparation of porous anodized aluminum template: Take a high-purity aluminum plate with a thickness of 1 mm, first clean it ultrasonically in a mixed solution of acetone and ethanol with a volume ratio of 1.5:1 for 30 minutes, and then clean it with ethanol with a volume ratio of 2:1 Polished in a mixed solution of perchloric acid (Ra ≤ 0.01μm) for 10 minutes; then, washed with deionized water and placed in a 0.35mol / L oxalic acid solution, anodized at a DC voltage of 25V for 0.7h, on a high-purity a...

Embodiment 3

[0045] The preparation technology of nano-zinc oxide temperature sensor specifically comprises the following steps:

[0046] 1) Preparation of nano-zinc oxide: first, Na 2 CO 3 and Zn(NO 3 ) 2 solution, under constant stirring, Zn(NO 3 ) 2 The solution was dropped into Na 2 CO 3 The reaction is carried out in the solution, and then, the precipitate is separated and dried, and calcined at 500°C for 30 minutes to obtain nano-zinc oxide, such as figure 2 shown;

[0047] 2) Preparation of porous anodized aluminum template: take a high-purity aluminum plate with a thickness of 3 mm, first clean it ultrasonically in a mixture of acetone and ethanol with a volume ratio of 2:1 for 15 minutes, and then clean it with ethanol with a volume ratio of 3:1 Polished in a mixed solution of perchloric acid (Ra ≤ 0.01μm) for 15 minutes; then, washed with deionized water and placed in a 0.25mol / L oxalic acid solution, anodized at a DC voltage of 30V for 1 hour, on the surface of a high-pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com