Water pipe lined with thin-walled stainless steel pipe and production method

A technology for stainless steel pipes and tap water pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems of easy collapse of pipe walls, achieve obvious energy saving effects, facilitate diameter reduction, and increase mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

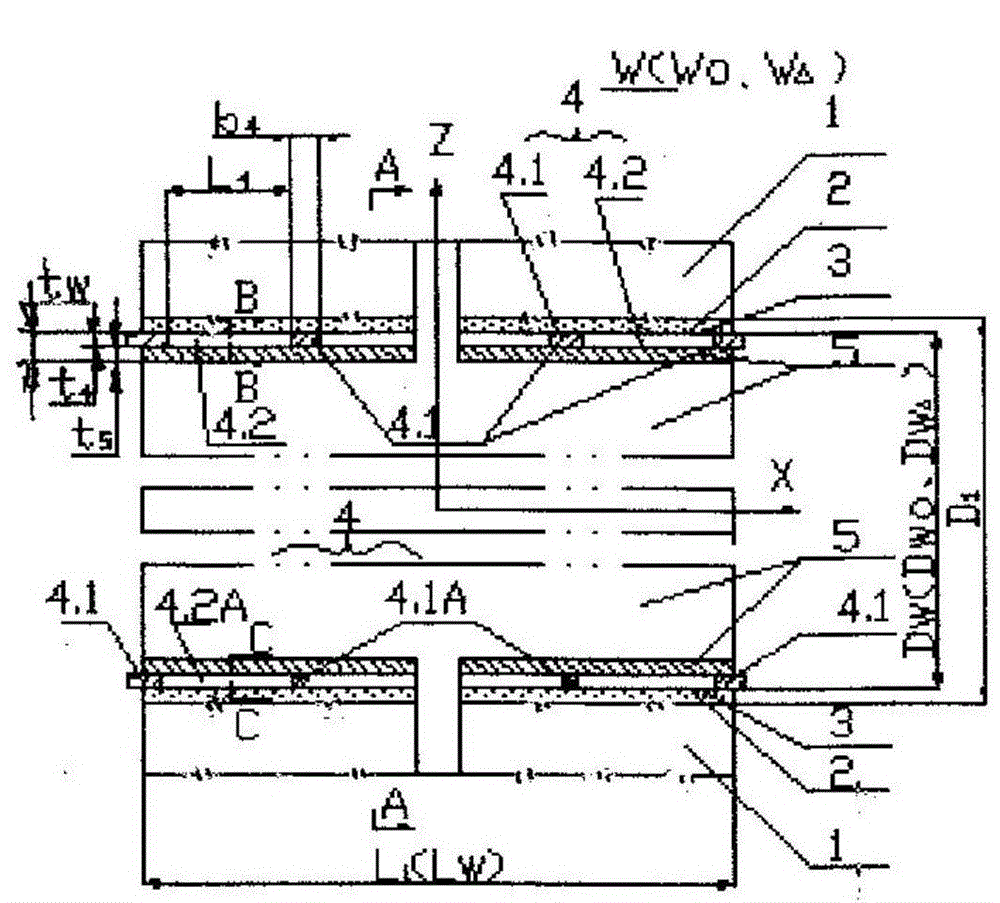

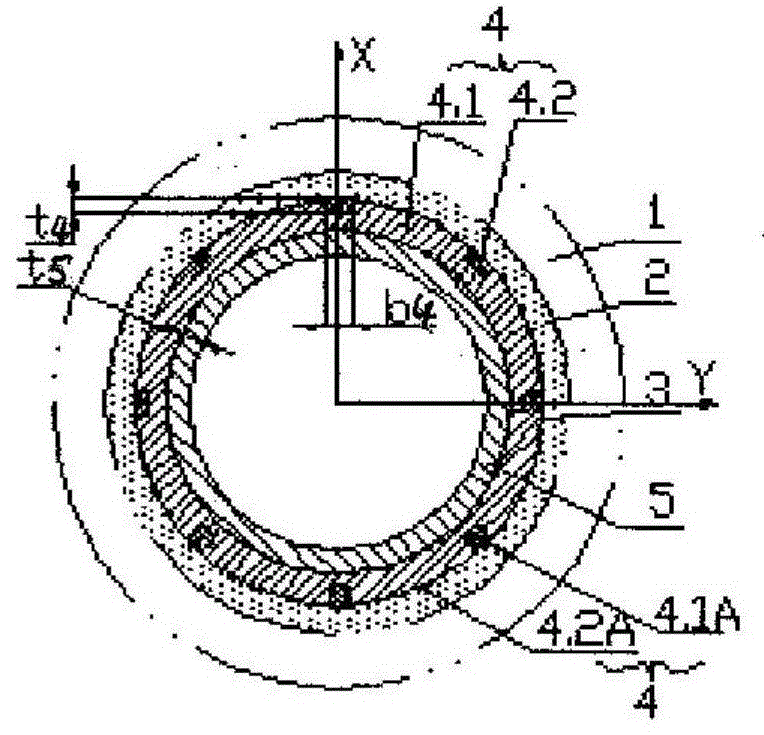

[0029] Example 1: see figure 1 Upper half, figure 2 upper semicircle, image 3 , Figure 5 , Figure 7 .

[0030] Embodiment 1 The tap water pipe lined with thin-wall stainless steel pipes includes: cement pipe 1 for conveying tap water, and the thin-wall stainless steel pipe lining pipe in the cement pipe adopts the following basic lining pipe W:

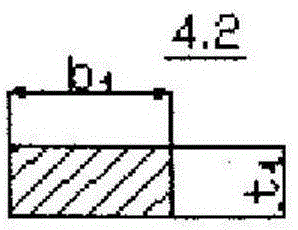

[0031] See figure 1 , the basic lining pipe W includes: ①The flow inner pipe 5 made of thin-walled stainless steel, the wall thickness of the flow inner pipe is t 5 Take 0.2-0.6mm; ② Fix the following frame 4 on the outer periphery of the flow-through inner tube: the ring and the connecting strip are made of thin-walled stainless steel strips. See figure 1 As shown in the upper half of the center, several evenly distributed parallel thin-walled stainless steel rings 4.1 perpendicular to X are arranged along the X direction of the frame axis, and the distance between two adjacent rings is L 4 =300-500mm. See figure 2 As ...

Embodiment 2

[0036] Example 2: see figure 1 lower half, figure 2 lower semicircle, Figure 4 , Figure 5 , Figure 7 .

[0037] This embodiment 2 is different from embodiment 1 except that the following features are all the same:

[0038] 1) see figure 2 As shown in the lower semicircle of the center line, the frame 4 is evenly distributed along the circumference of each ring to fix 8 thin-walled stainless steel wire connecting strips 4.2A in the X direction to connect the rings into an overall frame. See Figure 4 , wire diameter d 4 = 0.7-2mm.

[0039] 2) see figure 1 As shown in the lower half of the center line, several thin-walled stainless rings 4.1A that are uniformly distributed and parallel to X are arranged in the X direction of the frame 4. Except for the thin-walled stainless steel strips 4.1 at both axial ends, the middle ring Steel wires are used to make rings. The use of thin-walled stainless steel strip 4.1 at both ends is to facilitate the welding between adja...

Embodiment 3

[0040] Embodiment 3: see Figure 1-Figure 4

[0041] Present embodiment 3 is different from embodiment 1 except following feature, all the other are identical:

[0042] 1) Nominal outer diameter D W With cement pipe 1 nominal inner diameter D 1 The difference is 40-80mm, called the micro-reduced inner liner W Δ . Nominal outer diameter is D WΔ (See figure 1 ). 2) Cancellation of manufacturing method step 3) factory shrinkage in embodiment 1. Micro-diameter liner W Δ No reduction required. 3) Adopt the following steps 4) paint the inner wall of the cement pipe and the suit at the construction site, and replace step 4) of the production method in Example 1: 4) paint the inner wall of the cement pipe and the suit at the construction site: put the micro-diameter liner pipe W Δ Put it into the cement pipe, and then use a cement pump and an 18mm nozzle to fill the 20-40mm gap with cement mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com